Method and system for automatically controlling water level of inverted siphon in open channel

An inverted siphon and open channel technology, applied in control/regulation systems, liquid level control, non-electric variable control, etc., can solve the problems of insufficient water supply, downstream flow fluctuations, abandoned water, etc., to reduce costs, improve water delivery efficiency, The effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

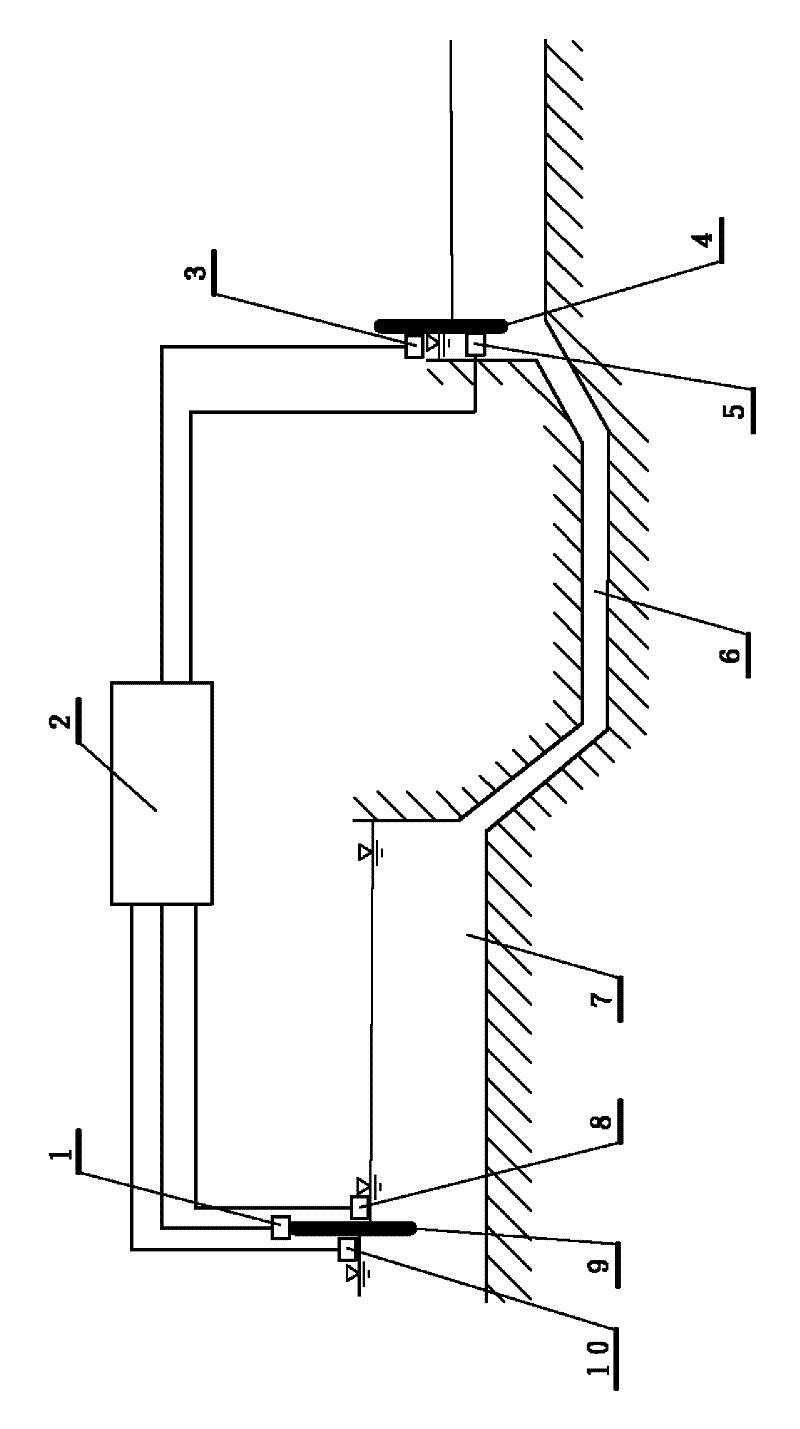

[0027] This embodiment is an automatic control system for open channel inverted siphon water level, such as figure 1 said. This embodiment includes: an open channel section 7, an inverted siphon 6 is connected in series downstream of the open channel section, a working gate 4 is arranged downstream of the inverted siphon, and the working gate is provided with an inverted siphon outlet water level sensor 3, an inverted siphon The siphon outlet flow sensor 5; the working gate opening and closing mechanism of the working gate is connected to the working gate PLC, and the inverted siphon outlet water level sensor, the inverted siphon outlet flow sensor and the working gate PLC are connected with the open channel section storage capacity calculation The control of the program is connected with the data processor 2, and a control gate 9 is arranged upstream of the open channel section, and the control gate is provided with a water level sensor 10 before the control gate, a water lev...

Embodiment 2

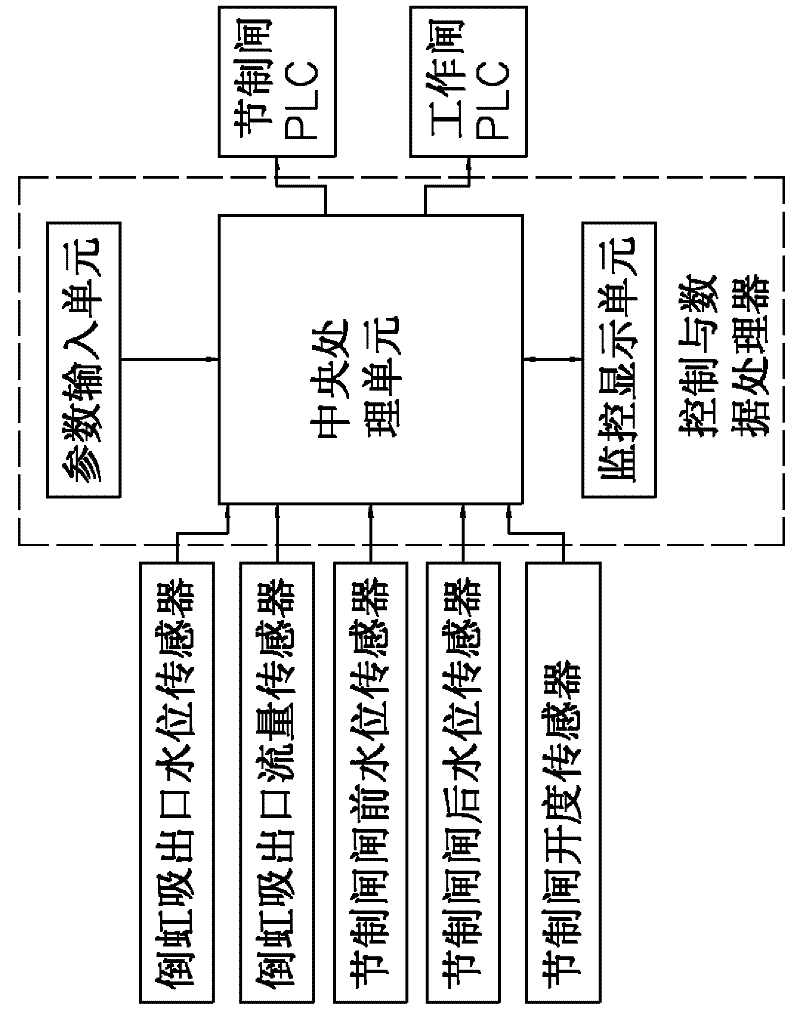

[0036] This embodiment is an improvement of the first embodiment, and it is the refinement of the control and data processor in the first embodiment, such as figure 2 shown. The control and data processor described in this embodiment includes: a central processing unit, a parameter input unit, and a monitor display unit.

[0037] The control and data processor described in this embodiment is an industrial control computer, which is a special industrial control device centered on an ARM chip. It can perform complex logic operations, and has an external storage system with considerable capacity, which can perform complex logic operations and control operations.

Embodiment 3

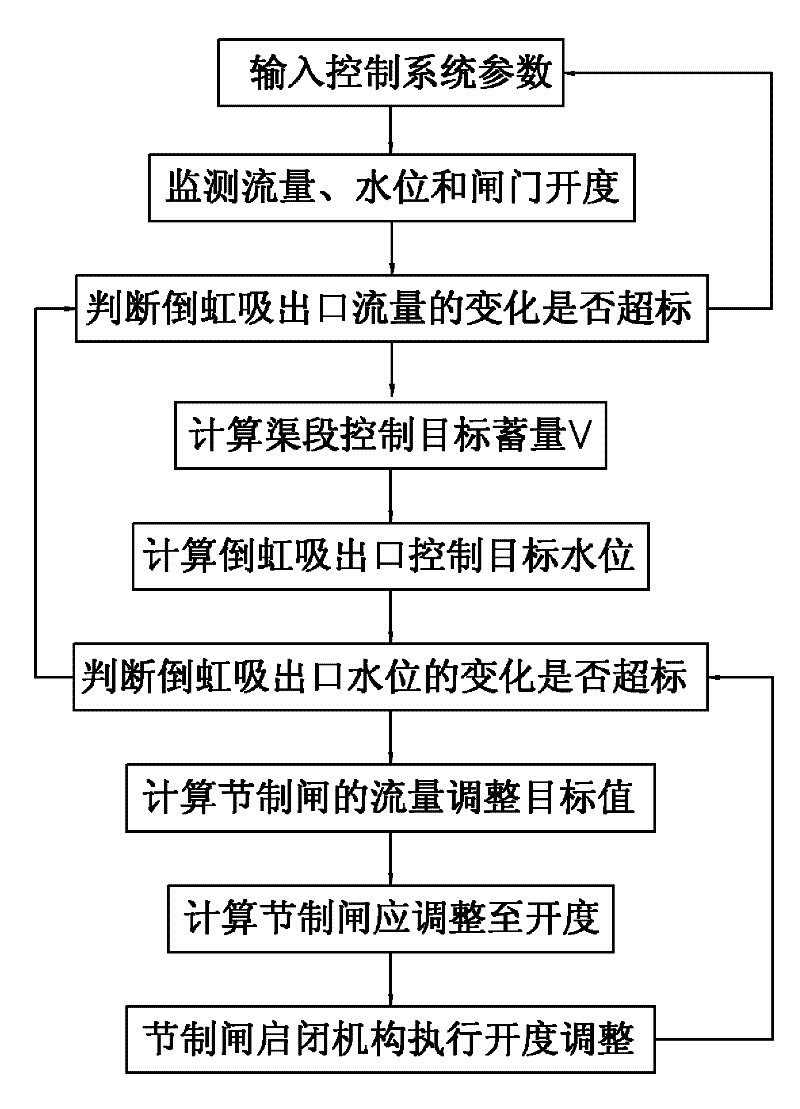

[0039] This embodiment is a method for automatically controlling the water level of an open channel inverted siphon using the system described in the above embodiments. The flow chart of the method is as follows image 3 shown. The variable controlled by the method described in this embodiment is the volume of the water body, that is, the "target storage capacity of the open channel section control", and the control of this variable is indirect, that is, based on the corresponding relationship between the volume of the water body and the water level, it is realized indirectly by controlling the water level Control over the volume of a body of water. In the control process, the target water level in front of the gate is not fixed, but changes dynamically with the change of flow. The steps of the method described in this embodiment are as follows:

[0040] Step 1: The step of inputting the parameters of the control system: it is used to set the physical parameters of the open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com