Multifunctional engine starter

An engine, multi-functional technology, applied in the direction of starting the engine, starting the motor with the engine, engine components, etc., can solve the problems of the starter burnout, the engine can not start normally, a large amount of battery power, etc., to prevent the starter from damage, solve the problem It is difficult to start and the effect of saving battery power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

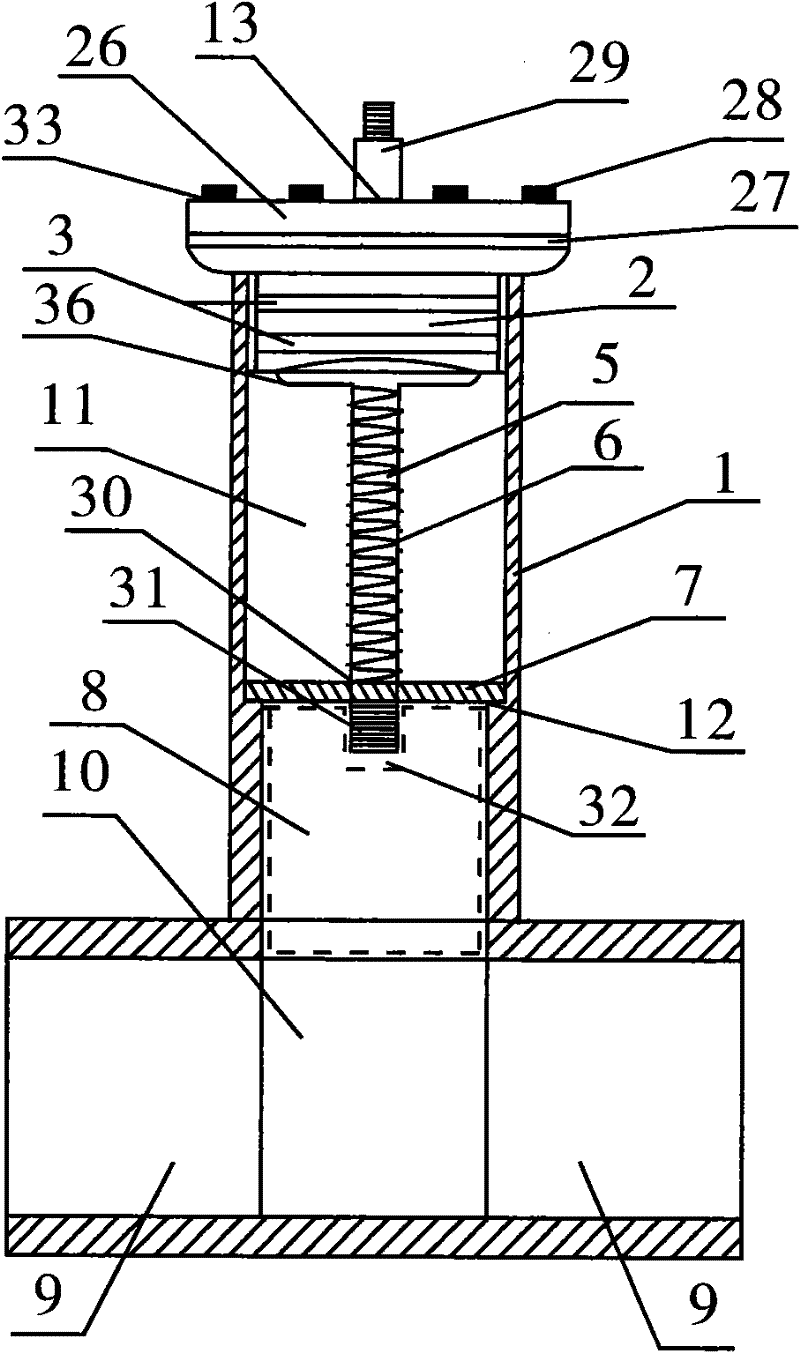

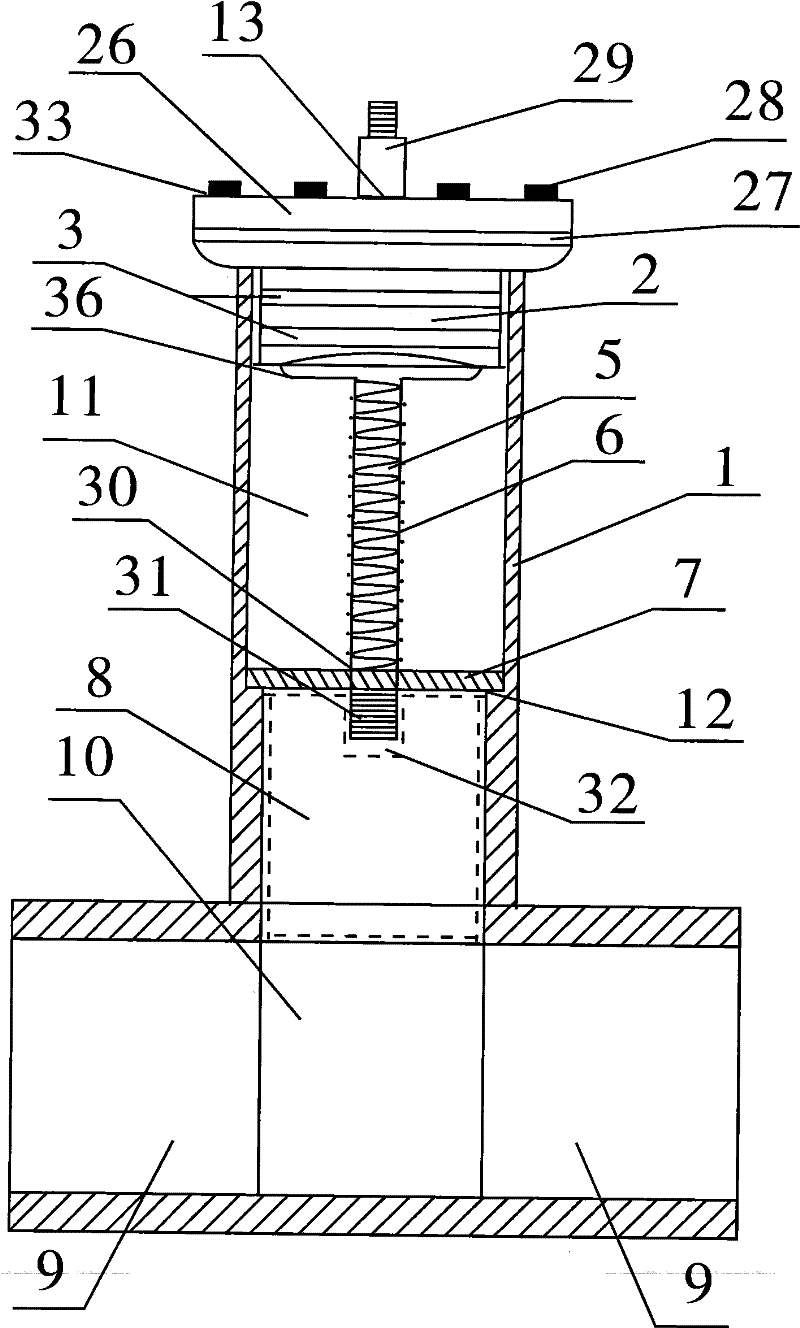

[0014] Embodiment one, such as figure 1 As shown, the product multifunctional engine booster of the present invention comprises a convex air cylinder block 1 assembled from outside to inside, an air cylinder gland 26, a cylinder gland pad 27, an intake and exhaust pipe switch joint 29, an air cylinder pressure Cover fastening bolt 28, pneumatic cylinder piston 2, pneumatic cylinder piston apron 3, umbrella section air ejector rod 5, umbrella section air ejector spring 6, umbrella section air ejector rod spring seat 7, cylindrical section air plug 8.

[0015] The two ends of the horizontal cylinder of the convex air pressure cylinder block 1 are breathers 9, one end is used to connect the engine air filter intake pipe joint, the other end connects the supercharger intake pipe or intake system, and other positions or parts are connected. Convex air pressure cylinder 1, the middle part of the inner cavity of the horizontal cylinder is formed with a section air plug working chamb...

Embodiment 2

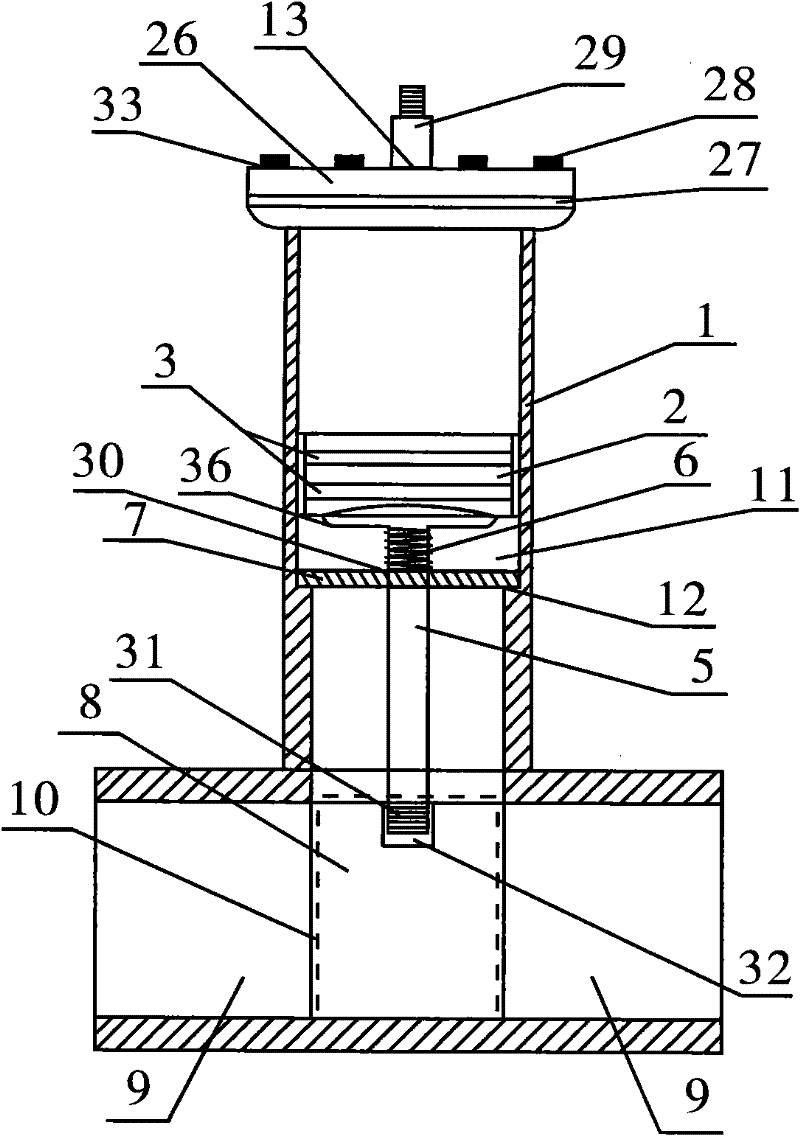

[0016] Embodiment two, such as figure 2 As shown, the product multifunctional engine booster of the present invention comprises a convex pneumatic cylinder block 1 assembled from the outside to the inside, a pneumatic cylinder gland 26, a pneumatic cylinder gland pad 27, an electronically controlled intake and exhaust pipe switch joint 29, Pneumatic cylinder gland bolt 28, pneumatic cylinder piston 2, pneumatic cylinder piston rubber ring 3, umbrella section air ejector rod 5, umbrella section air ejector spring 6, umbrella section air ejector spring seat 7, cylindrical section air ejector rod The plug 8 is assembled into a multifunctional engine booster. When working, the piston 2 of the pneumatic cylinder in the convex pneumatic cylinder 1 turns on the switch of the digital electronically controlled intake and exhaust pipe, and delivers compressed air through the air pipe through the joint 29 of the intake and exhaust pipe. , enter the air cylinder piston working chamber 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com