Bearing system for a wind turbine rotor

A technology of wind turbines and bearings, applied in the field of roller bearings, to achieve high life, improve fatigue life and usability, and avoid slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

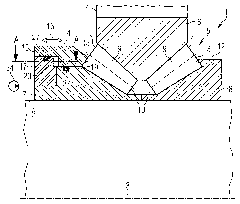

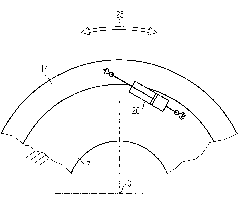

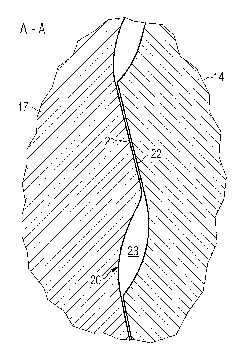

[0016] Such as Figure 1 to Figure 3 As shown, a wind turbine rotor comprises a bearing system 1 , a wind turbine shaft 2 with an axis 3 and a rotor hub 4 , wherein the shaft 2 is fixed and the rotor hub 3 is rotating. A rotor blade or a plurality of rotor blades (not shown) are mounted on the rotor hub 4 and extend in radial direction. The rotor hub 4 is supported to the rotor shaft 2 by the bearing system 1 such that the rotor hub 4 is pivotally mounted on the wind turbine shaft 2 . The bearing system 1 sustains radial forces, axial forces and tipping moments caused by wind loads, the weight of the blades and the rotor hub 4 and unbalance of the wind turbine rotor, etc. In order to provide a stable structure for a wind turbine rotor capable of withstanding operational loads, the bearing system 1 comprises double row tapered roller bearings 5 in an O-arrangement. The double-row tapered roller bearing 5 includes a split collar consisting of a first inner ring 7 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com