Piezoelectric stack pump provided with sensor

A piezoelectric stack and sensor technology, applied to pumps with flexible working elements, pumps, pump control, etc., can solve the problems of poor output accuracy and controllability of piezoelectric stack pumps, complex system volume, etc., and achieve easy access , the effect of accurate output flow and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

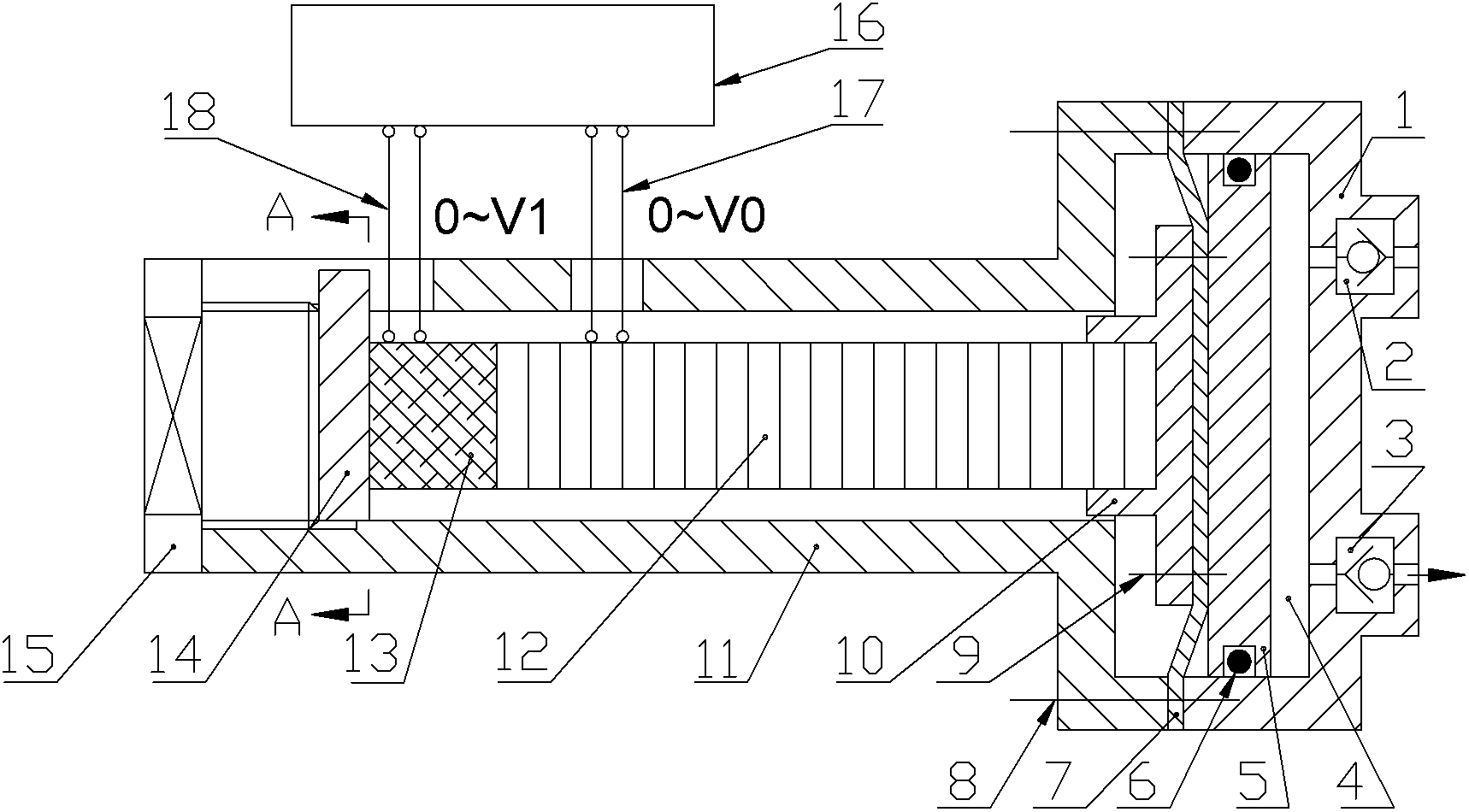

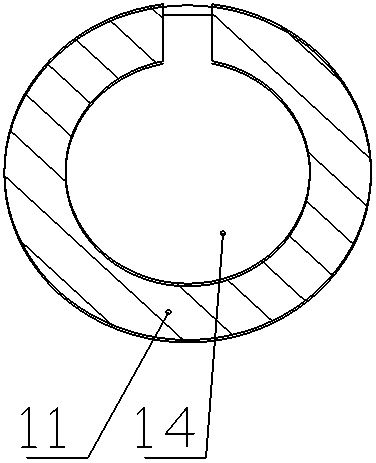

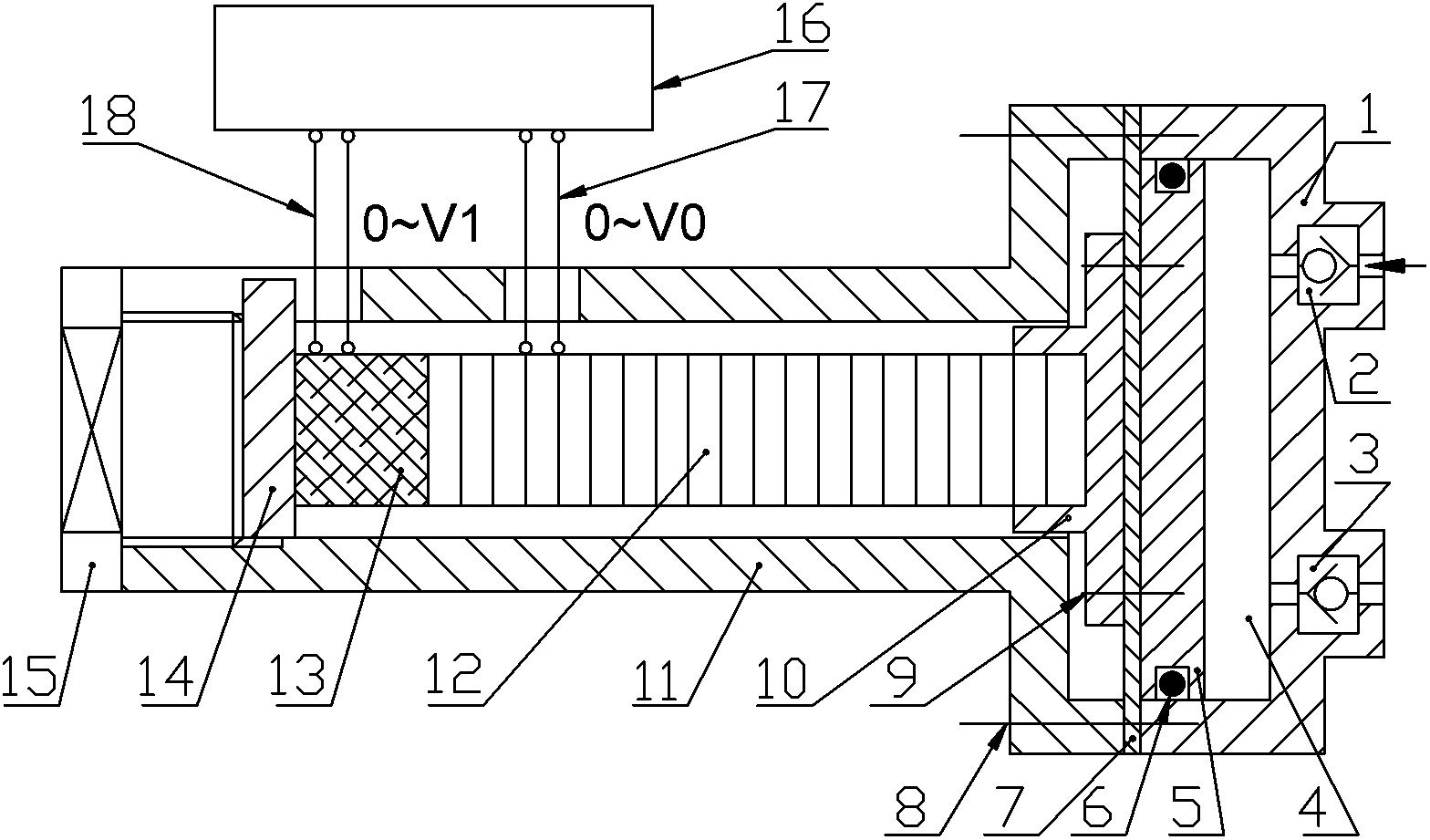

[0014] In the present invention, the piezoelectric stack 12 used for driving and the piezoelectric sensor 13 used for measurement are installed inside the pump body 11; The sheet 14 squeezes the piezoelectric sensor 13 and the piezoelectric stack 12 on the top block 10; the top block 10 is connected with the pump cavity diaphragm 7 and the piston 5 through the screw 9, and the pump cavity diaphragm 7 is connected with the pump body 11 through the screw 8 Connected with pump cover 1; inlet valve 2 and outlet valve 3 are installed on pump cover 1; piston 5 and sealing ring 6 installed on the piston, pump cover 1, inlet valve 2 and outlet valve 3 together constitute pump chamber 4 ; The piezoelectric sensor 13 and the piezoelectric stack 12 are respectively connected to the control power supply 16 through a wire group 18 and a wire group 2 17 .

[0015] Such as figure 1 As shown, after the control power supply 20 is turned on, the piezoelectric stack 12 is subjected to voltage (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com