Dilute oil lubricating bearing seat test system and test method thereof

A thin oil lubrication and testing system technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of large investment in debugging, measurement workload, large deviation of actual test results, and large manual testing workload, etc., to improve construction efficiency and Economic benefits, fast testing speed, and the effect of reducing manual workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

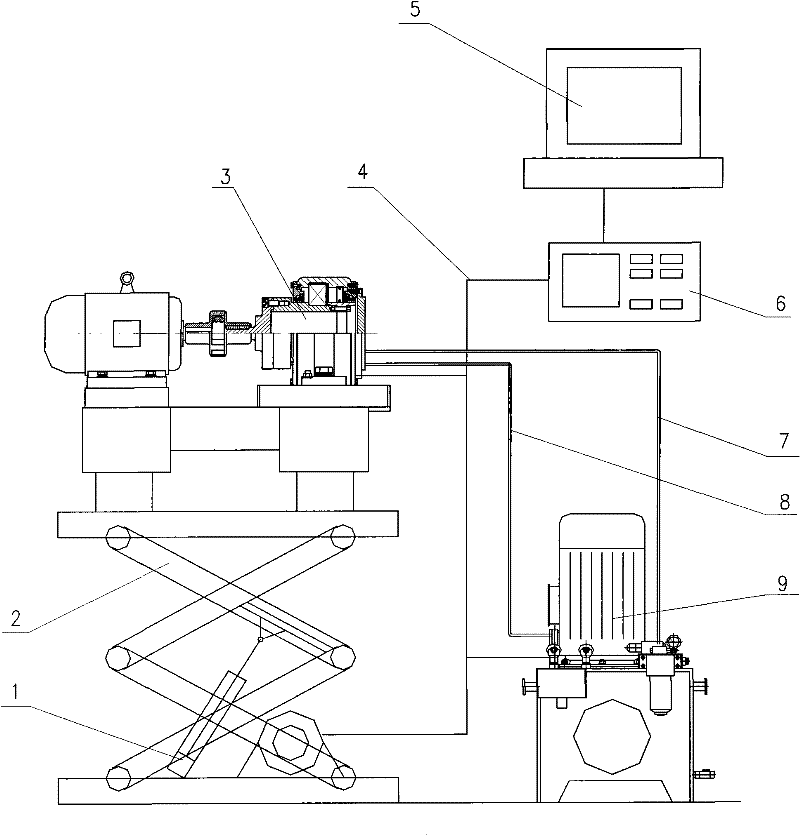

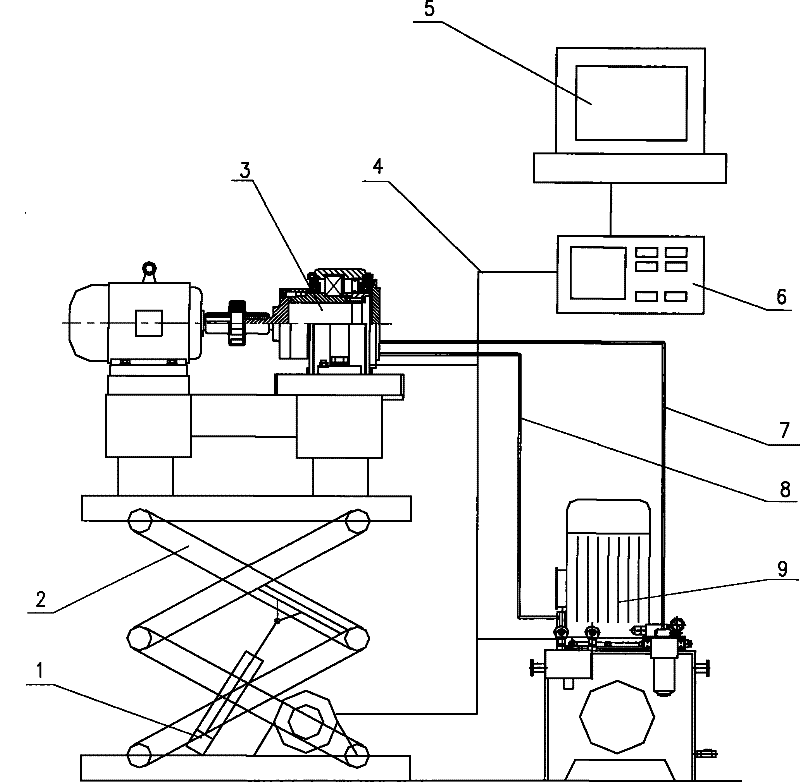

[0024] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] A thin oil lubricated bearing housing test system, the thin oil lubricated bearing housing 3 is driven by a motor and installed on the lifting platform 2 together; the hydraulic station 9 installed on the ground is connected to the thin oil lubricated housing by an oil inlet pipe The oil inlet hole of the bearing seat 3 and the oil outlet pipe of the thin oil lubricated bearing seat 3 are connected to the oil tank of the hydraulic station; Electrical connection between.

[0026] The lifting platform 2 is a rhombus folding structure with left and right cross support rods, and the included angle of the support rods is changed by the hydraulic pump 1 . Pushing out and shrinking the piston rod of the hydraulic pump 1 changes the included angle of the support rod, raises or lowers the lifting platform 2, and changes the oil return pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com