System and method for detecting quality of metal cap based on machine vision

A technology of machine vision and detection system, which is applied in the direction of instruments, measuring devices, optical testing flaws/defects, etc. It can solve the problems of high computational complexity of the least squares method, uneven illumination, and affecting the effectiveness of the algorithm, so as to improve the function Scalability, the effect of simplifying the decision-making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below through examples and in conjunction with the accompanying drawings.

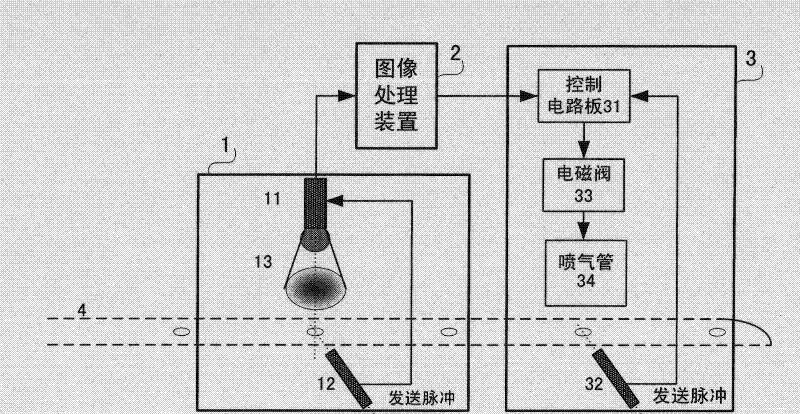

[0023] figure 1 It is a structural block diagram of the metal bottle cap quality inspection system based on machine vision in the present invention, including an optical imaging device 1, an image processing device 2, a rejecting device 3 and a conveyor belt 4, and the optical imaging device 1 includes an area array industrial camera 11, a first The light detection sensor 12 and the light source 13, wherein: the area array industrial camera 11 is respectively connected to the first light detection sensor 12 and the light source 13, the area array industrial camera 11 and the light source 13 are installed directly above the conveyor belt 4 plane, the area array industrial camera 11 and The light source 13 has a common center line and the center line is perpendicular to the plane of the conveyor belt 4. The first photodetec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com