Infrared zooming lens

A zoom lens and infrared technology, applied in the field of infrared zoom lens, can solve the problems of low refractive index of zinc sulfide, difficult aberration correction, large infrared absorption, etc., and achieve easy field curvature and astigmatism, light weight, and less infrared absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

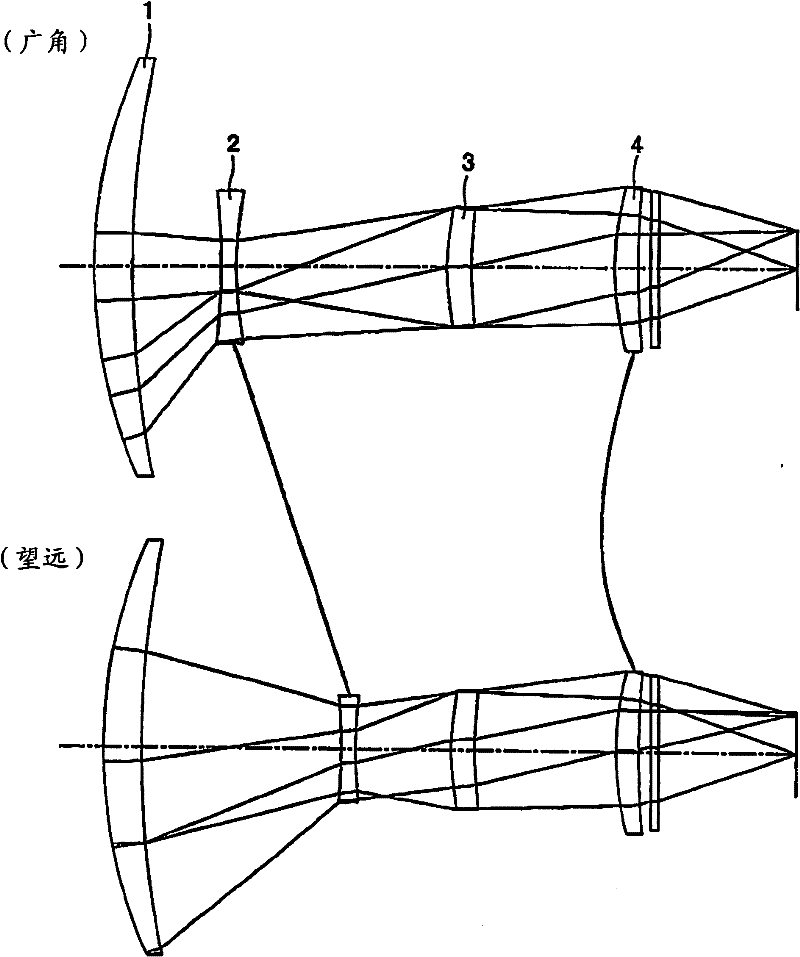

Image

Examples

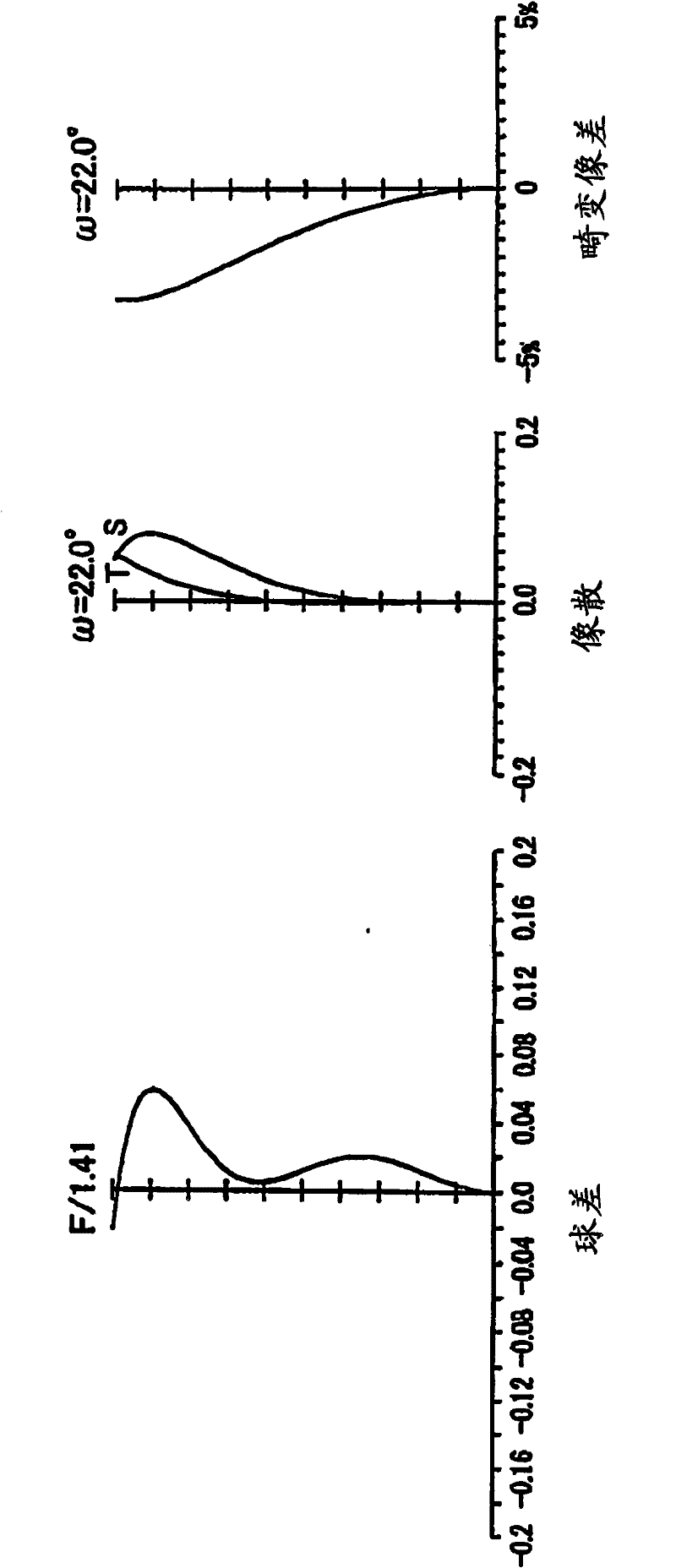

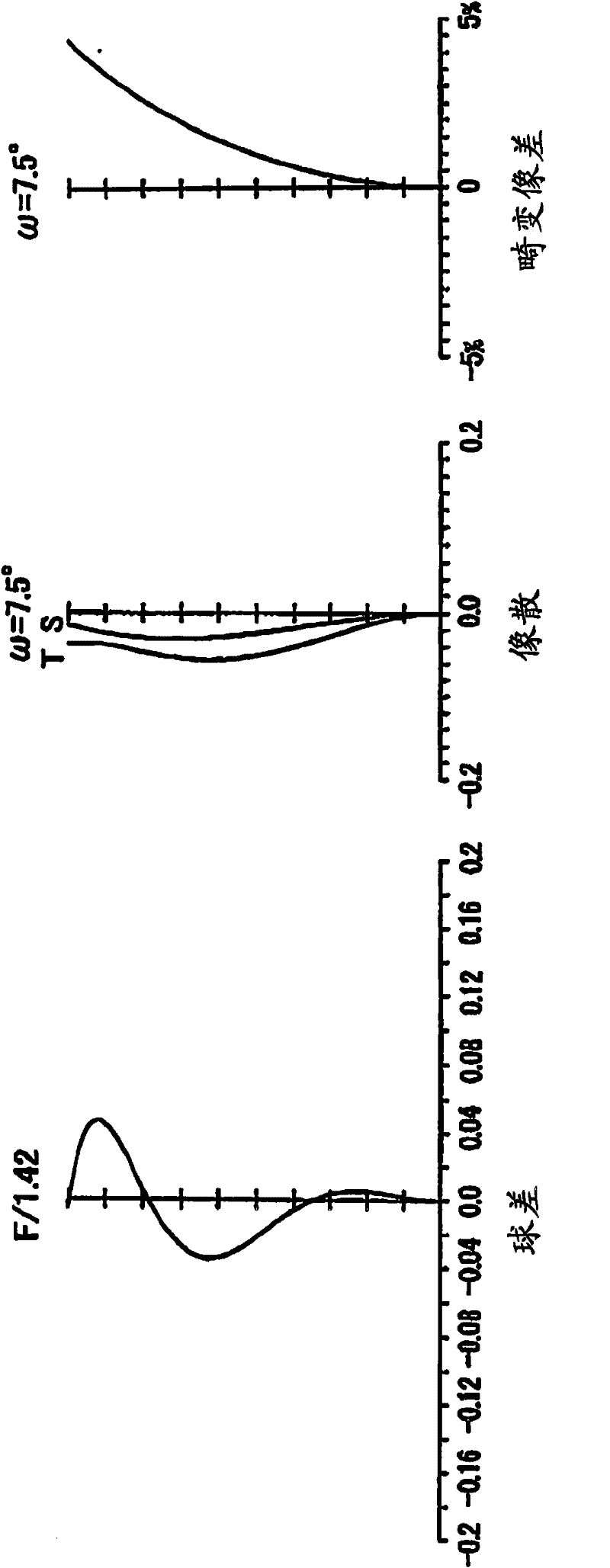

no. 1 Embodiment approach

[0084] The lens data and the like of the first embodiment are listed below.

[0085]

[0086] The part where the lens distance changes with the change of the focal length is represented by D(i).

[0087] The surface with the ASPH symbol after the lens surface serial number is an aspheric surface. The expression of the aspheric surface shape is expressed by the following formula, where the height perpendicular to the optical axis is H, the displacement of the height H in the direction of the optical axis when the top of the lens surface is taken as the origin is X(H), and the paraxial curvature The radius is R, the cone coefficient is ε, the 2nd aspheric coefficient is A, the 4th aspheric coefficient is B, the 6th aspheric coefficient is C, the 8th aspheric coefficient is D, and the 10th aspheric coefficient is E.

[0088] X = H 2 / R 1 ...

no. 2 Embodiment approach

[0094] Lens data and the like of the second embodiment are listed below.

[0095]

[0096] Aspheric Data

[0097]

[0098] Lens Group Interval for Zoom Action

[0099]

no. 3 Embodiment approach

[0101] Lens data and the like of the third embodiment are listed below.

[0102]

[0103] Aspheric Data

[0104]

[0105] Lens Group Interval for Zoom Action

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com