Joint debugging device and joint debugging method for workpiece table interferometer and mask table interferometer

An interferometer and mask stage technology, which is applied to exposure devices, measuring devices, optical devices, etc. in the photoengraving process, can solve the problems of difficult operation, large spacing, and complex lithography machine structure, and achieves flexible and easy use. Loading and unloading, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

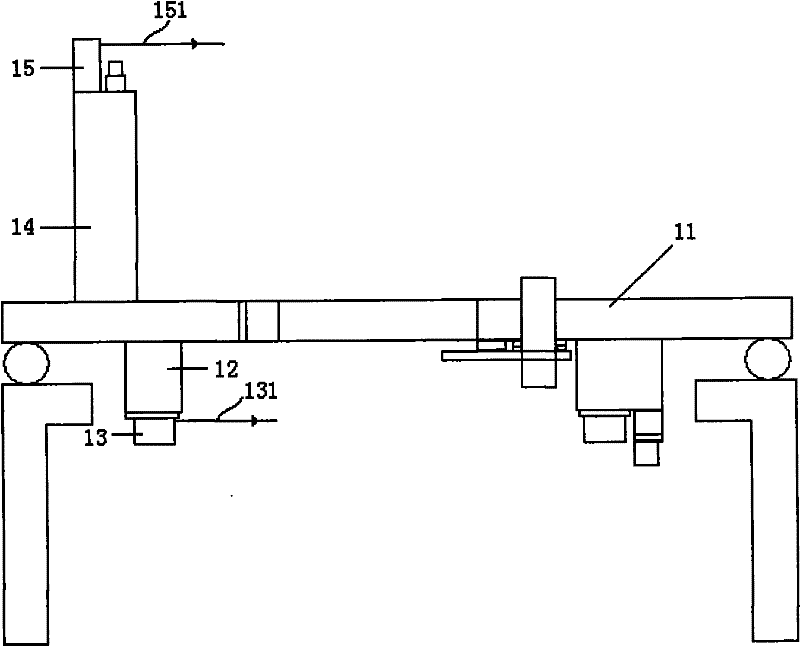

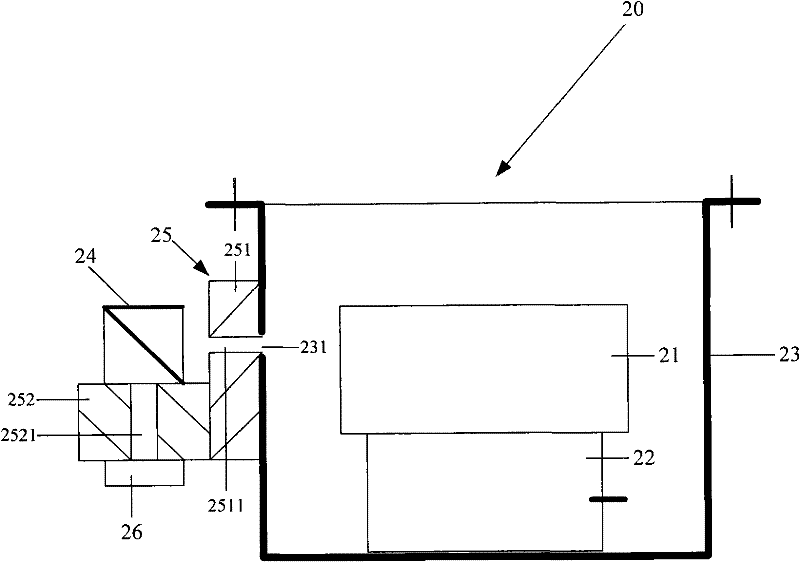

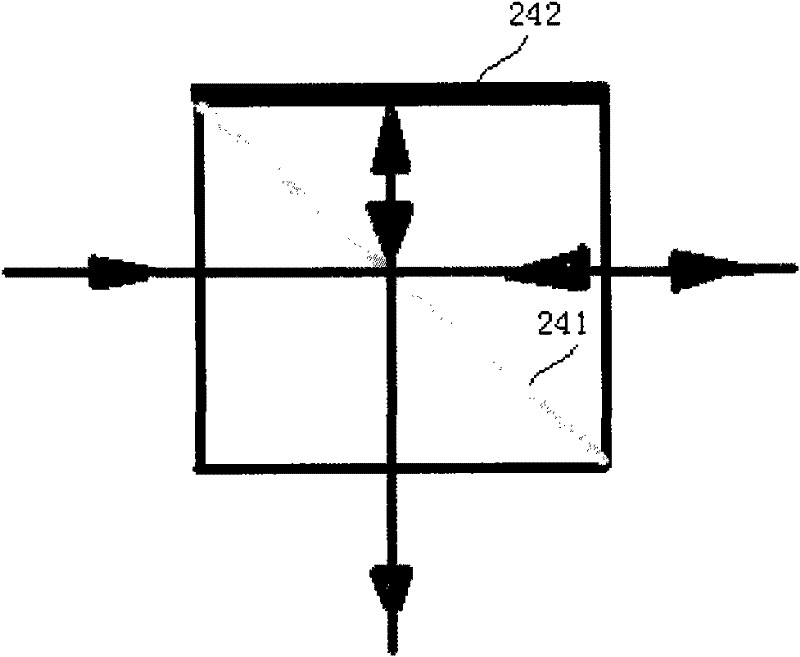

[0036] The following will combine Figure 2 ~ Figure 11 The joint debugging device and joint debugging method of the workpiece stage interferometer and the mask stage interferometer of the present invention will be further described in detail.

[0037] The joint debugging device of the workpiece stage interferometer and the mask stage interferometer of the present invention is used for online detection and adjustment of the workpiece stage interferometer and the mask stage interferometer, including multi-faceted mirror detection tooling, beam splitting prism group tooling and multi-faceted mirror reflection tooling ;

[0038] The multi-faceted mirror detection tool is used to adjust the workpiece table interferometer to lock the position of the workpiece table interferometer;

[0039] The dichroic prism group tooling is used to adjust the reflection tooling of the polygon mirror to lock the position of the reflection tool of the polygon mirror;

[0040] The dichroic prism gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com