Electric control system of corrosion converting machine

An electromechanical system and chemical corrosion technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid devices, etc., can solve the problem that the corrosion machine is in a waiting state, the effective working time is not fully utilized, the program control of the electronic control system and the process flow are inconsistent Reasonable and other issues, to achieve the effect of reducing water supply time, reducing water and power consumption, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

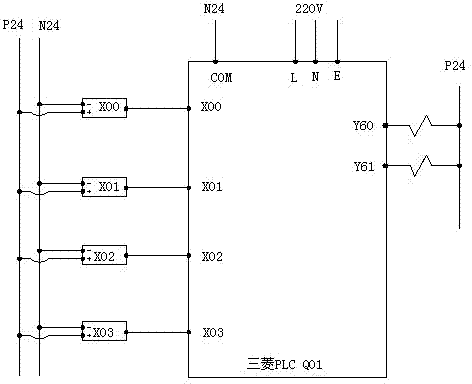

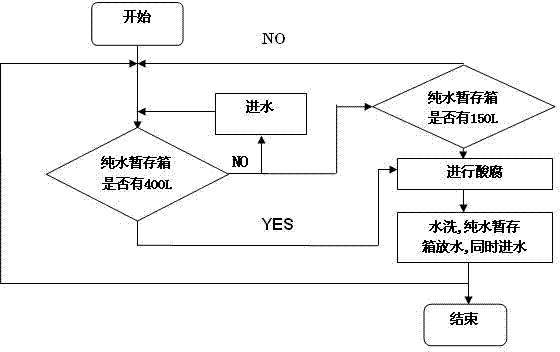

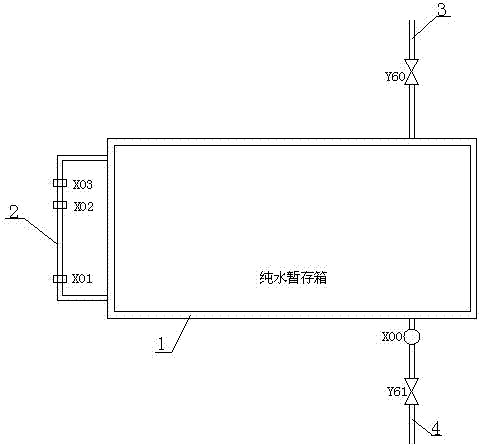

[0028] Such as figure 1 , figure 2 and image 3 As shown, the electric control system of the anti-corrosion machine includes PLC and liquid level sensor. The four digital input terminals of PLC are respectively connected with liquid level sensor X01, liquid level sensor X02, liquid level sensor X03 and a water outlet flow meter X00. The two output relays respectively control the water inlet valve Y60 and the water outlet valve Y61; the outer wall of the pure water temporary storage box 1 of the antiseptic machine is provided with the water pipe 2 connected to the pure water temporary storage box 1, the liquid level sensor X03, the liquid level sensor X02 and The liquid level sensor X01 is installed on the water pipe 2 from top to bottom, the water inlet valve Y60 is installed on the water inlet pipe 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com