Electronic assembly body

A technology of assembly and electronic components, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of poor heat dissipation efficiency, low thermal conductivity, poor heat conduction effect of circuit boards, etc., and achieve good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the electronic device proposed in accordance with the present invention will be described in detail below with reference to the drawings and embodiments Rear.

[0032] [First set of embodiments]

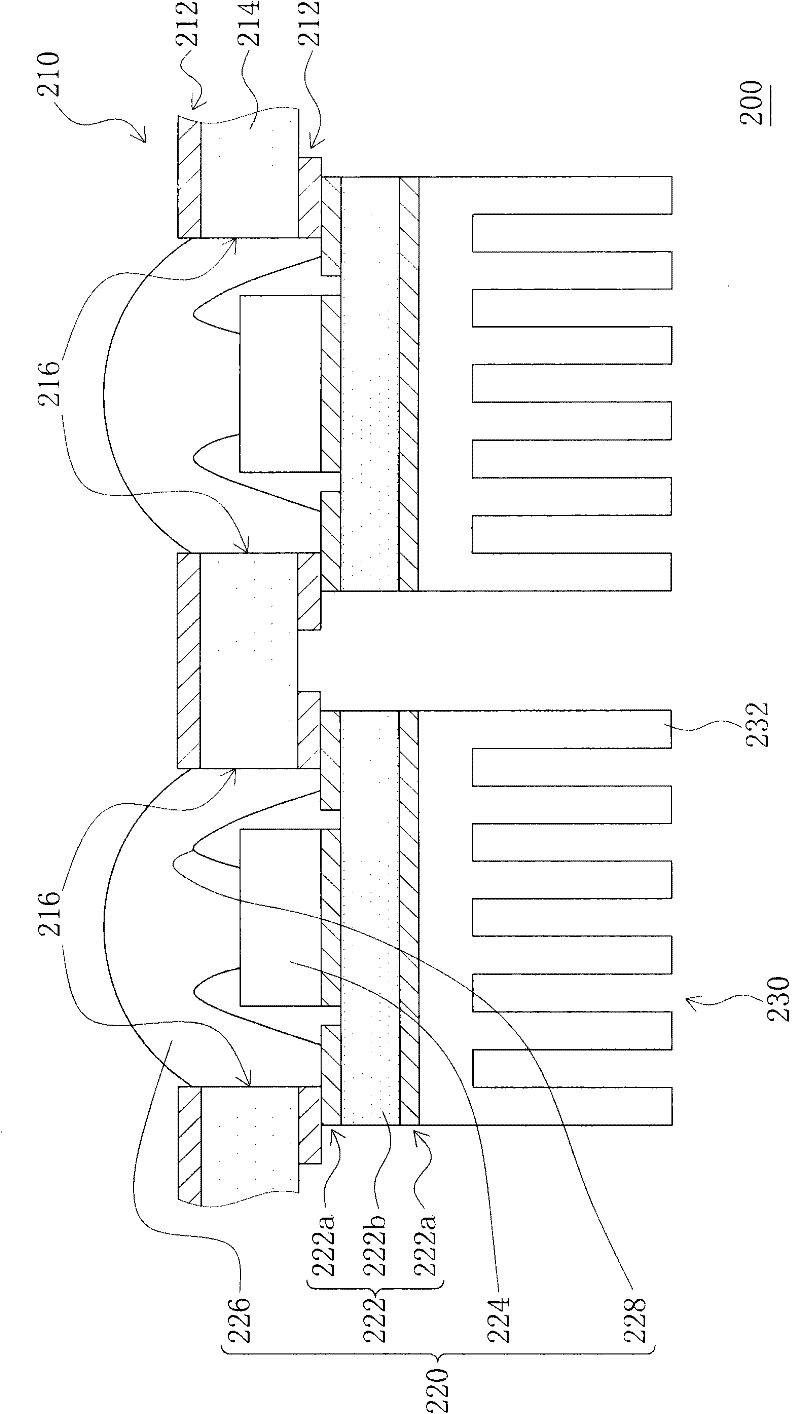

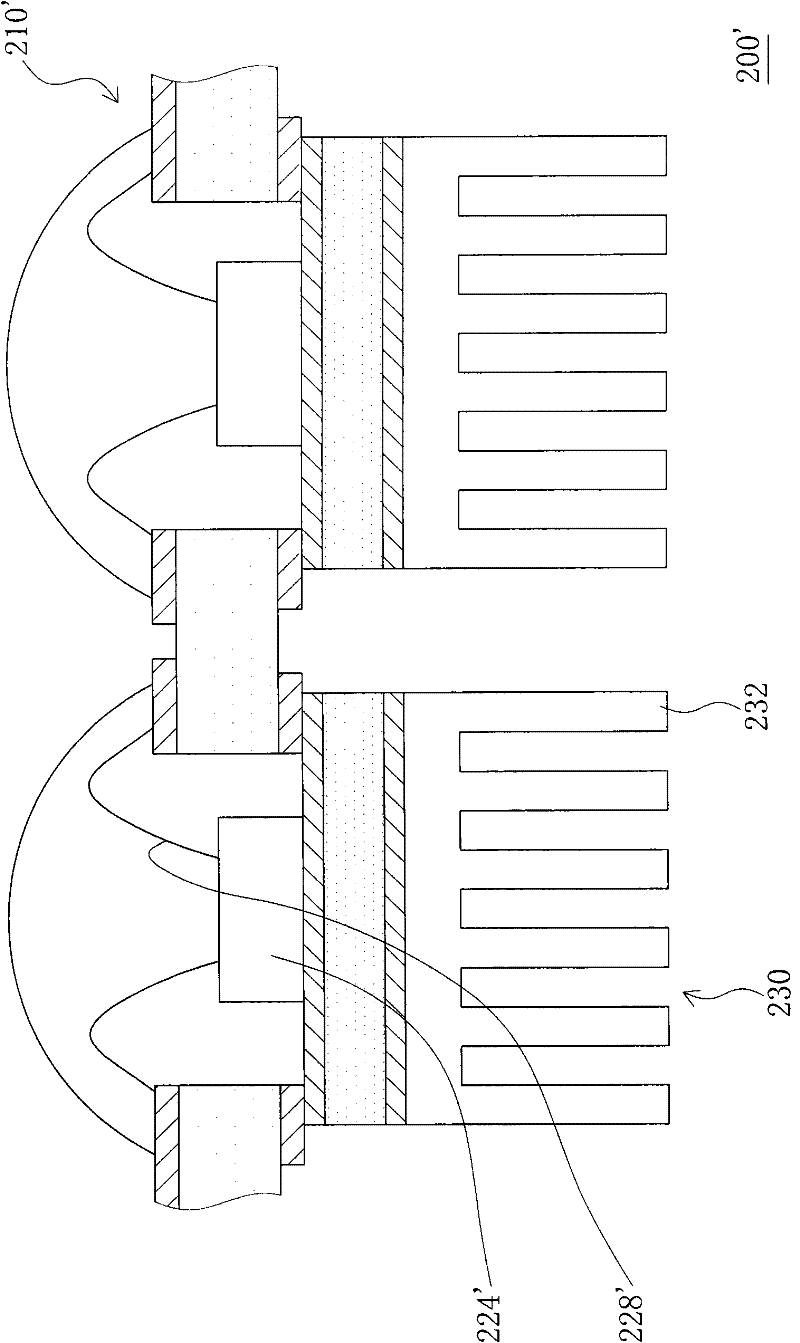

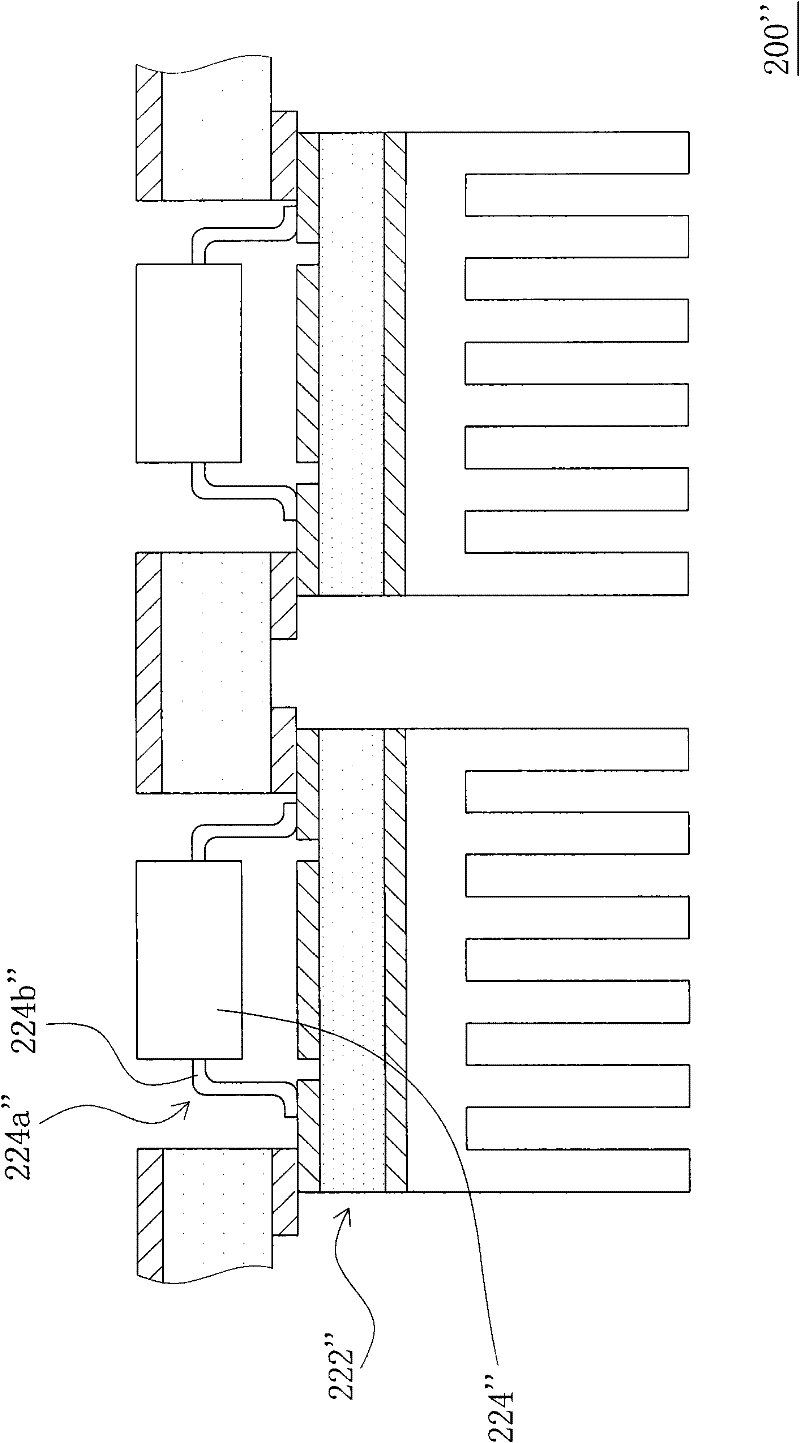

[0033] Figure 1A A schematic cross-sectional view of an electronic assembly according to the first group of embodiments of the present invention is shown. Please refer to Figure 1A The electronic assembly 200 of the first group of embodiments includes a first substrate 210, a plurality of electronic modules 220, and a plurality of heat dissipation devices 230. The first substrate 210 includes two first conductive layers 212 and a first insulating layer 214 and has a plurality of through holes 216. The first conductive layers 212 are respectively disposed on two opposite sides of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com