Straight thread rolling mechanical integrated machine

A straight thread, all-in-one technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as difficulty in adapting to the needs of buildings, reducing the performance of steel bars, weakening the strength of threaded joints, etc., to achieve compact structure and high cost performance. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The straight thread rolling machine will be further described below in conjunction with the accompanying drawings.

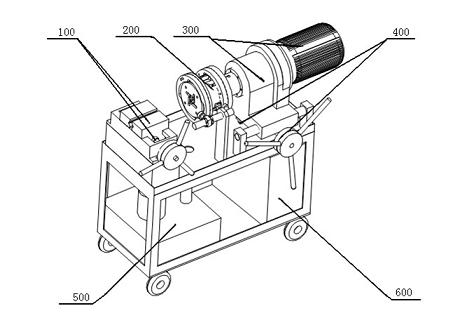

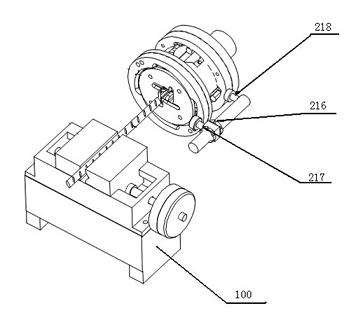

[0033] Such as figure 1 , the component structure of the straight thread rolling machine is mainly composed of a steel bar clamping mechanism 100,

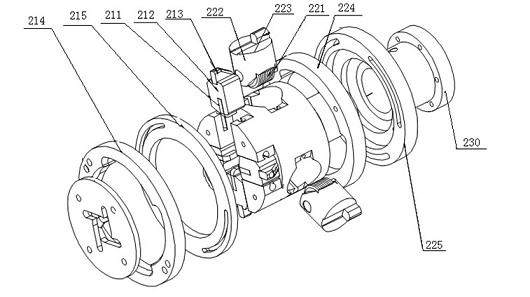

[0034] Rolling head 200, geared motor 300, feed system 400, cooling system 500, electrical control system 600, rolling head 200 includes a stripping knife mechanism 210 and a roller mechanism 220, and is connected to the output end of the geared motor 300 through a connecting flange 230 . The front end of the rolling head 200 is equipped with a stripping knife mechanism 210, and the rear end is equipped with a roller mechanism 220. The feeding system 400 is installed under the rolling head 200 and the reduction motor 300, and is cooperating with the above two components for transmission; at the position below the feeding system 400 Install the electrical control system 600; the axial linkage side of the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com