Manufacturing process of bamboo fiber and mulberry silk interwoven color woven taffeta

A production process, the technology of mulberry silk, which is applied in the direction of fabric, textile, textile and papermaking, etc., can solve the problems that the production process cannot be applied to mulberry silk, the fabric has poor color flashing effect and drape, and the difference between appearance and perception is large, so as to achieve the goal of fabric The flashing effect is obvious, the appearance and wearing comfort are guaranteed, and the effect of making up for poor anti-wrinkle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

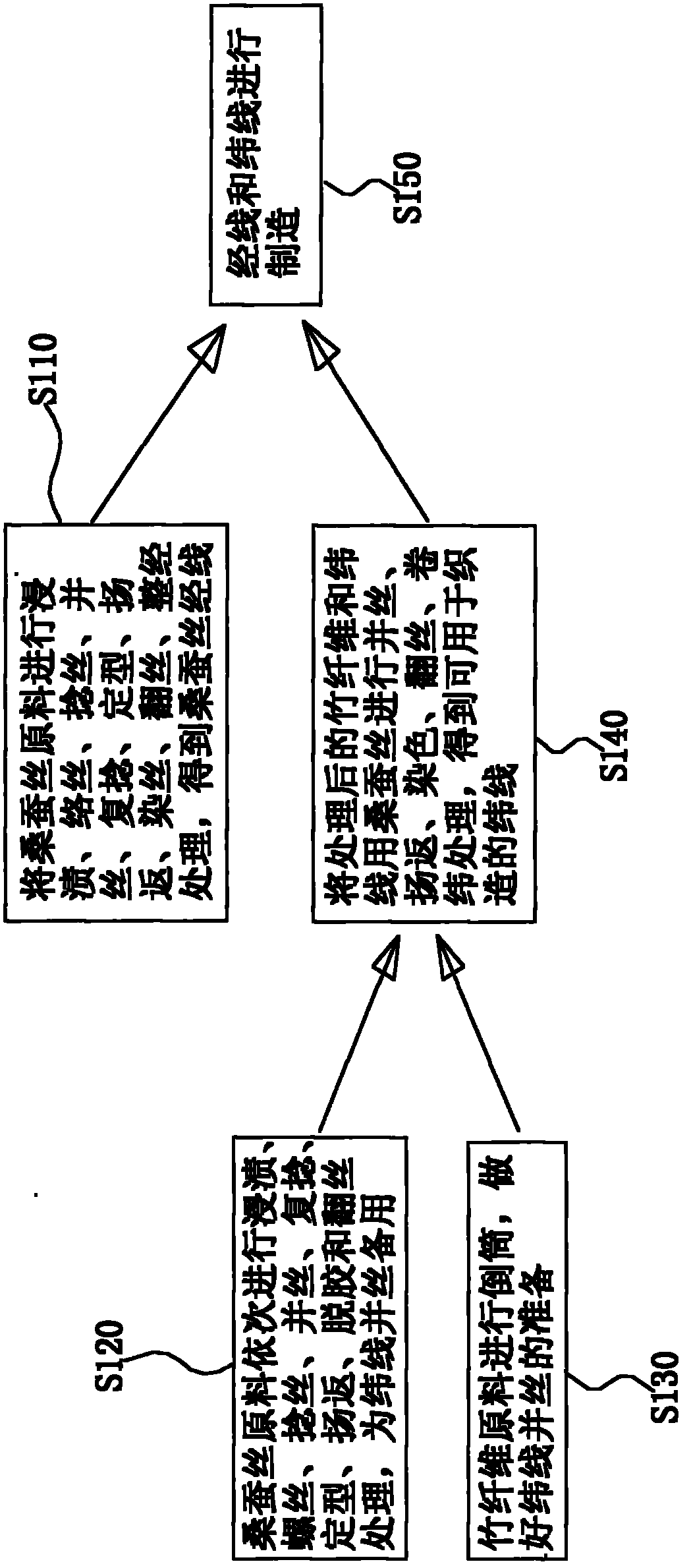

[0026] The bamboo fiber and mulberry silk interweaving yarn-dyed taffeta is a fabric woven with bamboo fiber and mulberry silk as the weft and mulberry silk as the warp. The weft thread is a mixed fiber made of bamboo fiber and degummed silkworm linear silk, which are combined, then hoisted and twisted, and dyed. Wherein the total amount percentage that bamboo fiber accounts for fabric is about 60%. The preparation method of the bamboo fiber and mulberry silk interwoven yarn-dyed taffeta comprises the steps of impregnating and degumming the mulberry silk, then doubling, lifting and dyeing with the bamboo fiber, so as to obtain the weft of the combined raw material of bamboo fiber and mulberry silk; first The mulberry silk for making wefts is soaked with a raw silk dipping auxiliary agent for about 4 hours, and then dried naturally at room temperature for about 24 hours. Then use one of the soap alkali method, synthetic detergent method or synthetic detergent-enzyme method to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com