Process for producing high-precision special threaded sleeve pipe coupling

A special thread and casing coupling technology, applied in the direction of threaded connection, casing, manufacturing tools, etc., can solve the problems of large deviation of casing coupling wall thickness, low equipment investment, poor sealing performance, etc. The effect of high threaded connection strength and large performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

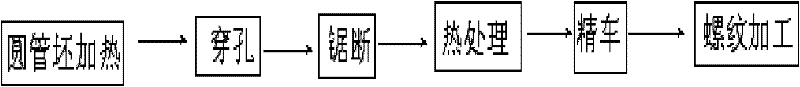

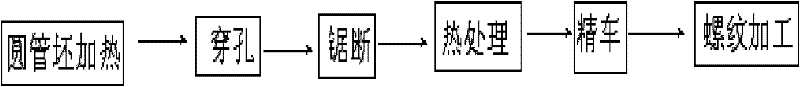

[0029] A method for manufacturing high-precision special threaded casing couplings,

[0030] Material: round tube billet

[0031] The alloy composition and content percentage of the round tube billet are:

[0032] C0.34-0.40%, Si0.20-0.50%, Mn1.30-1.55%, P≤0.020%, S≤0.010%, Cu≤0.20%, Ni≤0.20%, Cr≤0.50%, Mo≤0.30% , V≤0.10%, Ti≤0.10%, B0.0001-0.0003%, and the balance is Fe.

[0033] The specific processing steps are as follows:

[0034] (1) round tube billet heating

[0035] The round tube is heated in a regenerative annular heating furnace. During heating, the tube and the furnace bottom rotate together. The heating temperature is 1210±10°C, and the heating time is 55-65°C. The temperature difference between the ends of the tube is not greater than ±10°C. ;

[0036] (2) perforation

[0037] The heated round tube is pierced with a three-roller piercer. After piercing, it is in the shape of a capillary tube. The rolling angle is 15°±2°, the maximum elongation coefficient is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com