In-situ temperature measuring thermocouple on diamond anvil cell and preparation method thereof

A diamond-to-anvil, in-situ temperature technology, which is applied in the direction of measuring heat, thermometers, measuring devices, etc., can solve the problems of inaccurate measurement, large temperature measurement error, and in-situ temperature measurement problems that have not been well solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

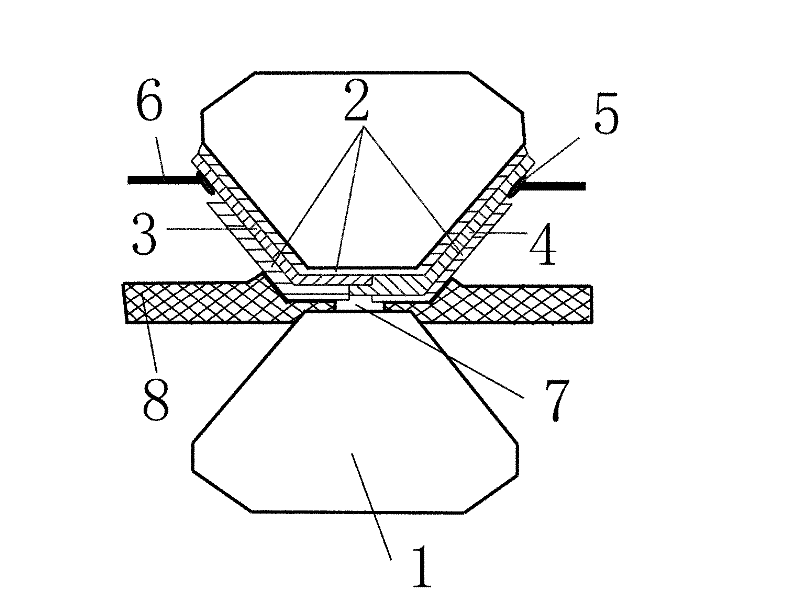

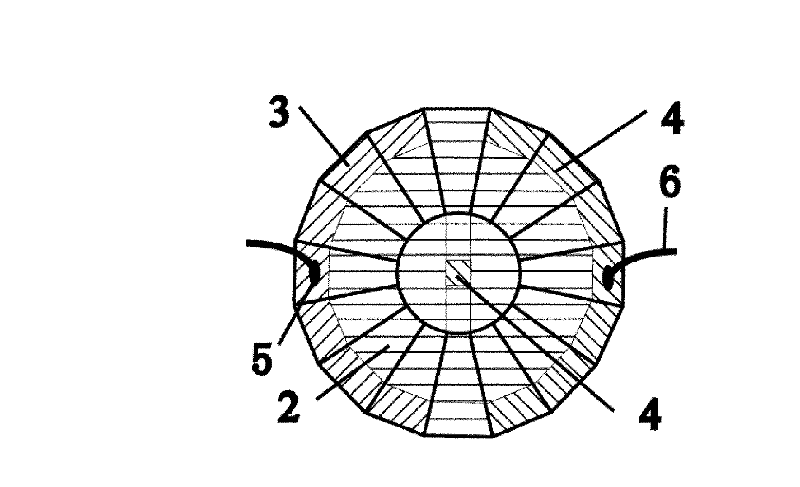

[0034] Example 1 combined figure 1 , 2 Explain the structure of the present invention

[0035] exist figure 1 , 2 Among them, 1 is a diamond anvil, 2 is an aluminum oxide film, 3 is a tungsten film, 4 is a tantalum film, 5 is a conductive silver paste, 6 is a copper wire, 7 is a sample cavity, and 8 is a metal gasket.

[0036] figure 1 A schematic diagram of the assembled DAC device with a W-Ta thermocouple is given, in which the diamond anvil has two diamond anvils up and down, and the upper diamond anvil 1 is prepared with a W-Ta thermoelectric device by magnetron sputtering. Even; between the anvil surface of two diamond anvils up and down and the hole that has on metal spacer 8 forms sample chamber 7, is used for placing measured sample; Through each deposition layer (aluminum oxide film 2, tungsten film 3, The profile of the tantalum film 4) can clearly show the positional relationship of each deposited layer, wherein the aluminum oxide film 2 of the inner layer depo...

Embodiment 2

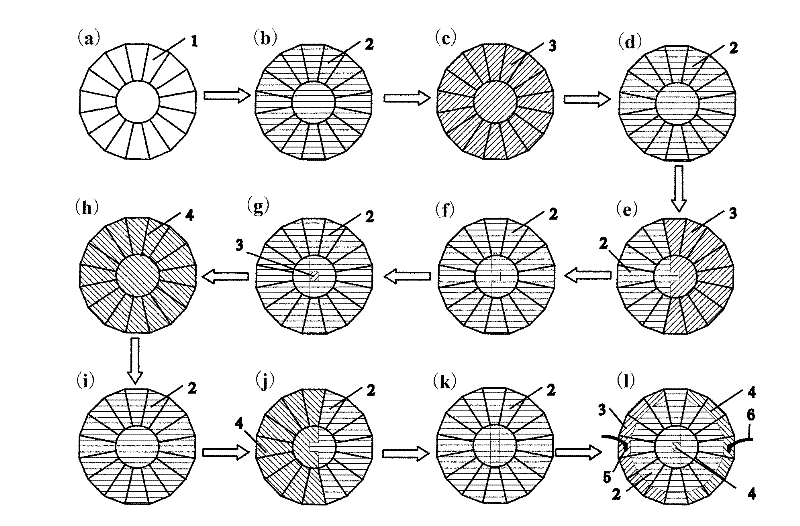

[0038] Example 2 combined image 3 Illustrate the preparation process of W-Ta thermocouple of the present invention

[0039] The present invention is accomplished through following technological process [whole process is as image 3 (a)-(f)]:

[0040] Step 1: Use conventional methods to remove stains on the surface of the diamond anvil 1. You can soak the diamond anvil in a mixture of acetone and alcohol for 20 minutes to remove surface stains. After taking it out, rinse it with deionized water. Such as image 3 (a) shown.

[0041] The second step: after drying, put it into the vacuum chamber of the magnetron sputtering device, and use the magnetron sputtering method to deposit the aluminum oxide film 2 on the surface of the diamond as the heat insulation between the sample chamber 7 and the diamond anvil 1 layer. Such as image 3 (b) shown.

[0042] In the sputtering process, metal aluminum is used as the target material, oxygen and argon with a flow ratio of 30:2.0~3....

Embodiment 3

[0059] Proofreading of W-Ta thermocouple under embodiment 3 normal pressure

[0060] A standard K-type thermocouple (NiSi-NiCr) is used to calibrate the variation relationship of the thermoelectric potential of the W-Ta thermocouple of the present invention with temperature, and the calibrated temperature range is 26-350°C. In the experiment, a copper wire with a diameter of 100 μm was selected as the compensation wire, and the connection between the copper wire 6 and the W film 3 and Ta film 4 on the side of the diamond anvil 1 was connected by conductive silver paste 5 leads. The advantage of this method is that it is easy to operate, the contact resistance is small, and the repeatability of the experiment is good.

[0061] From Figure 4 It can be seen from the figure that as the temperature increases, the thermoelectric potential of the W-Ta thermocouple increases gradually, and the temperature T and the thermoelectric potential V show a good linear relationship. When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com