Non-wetting coating on a fluid ejector

A fluid ejector, wetting technology, used in coatings, devices that apply liquid to surfaces, printing, etc., can solve the problems of expensive coatings, not durable coatings, difficult to form patterns, etc., to improve durability, improve Reliability, effect of improved droplet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

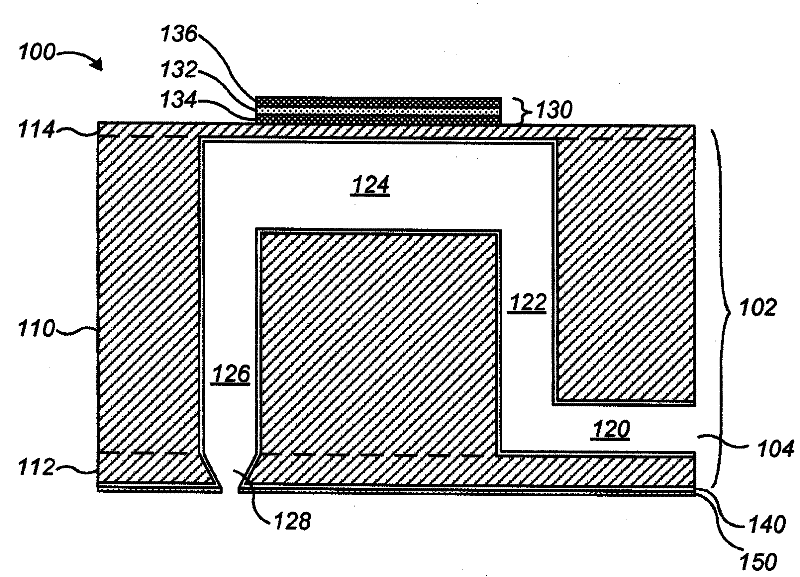

[0026] Figure 1A Is a cross-sectional view of a fluid ejector 100 (for example, an inkjet print head nozzle), aspects of the fluid ejector not discussed here can be implemented as described in US Patent Publication No. 2008-0020573, which The content of is hereby incorporated into this article for reference.

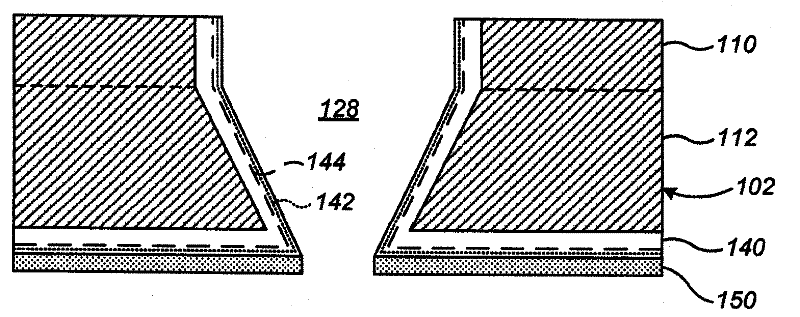

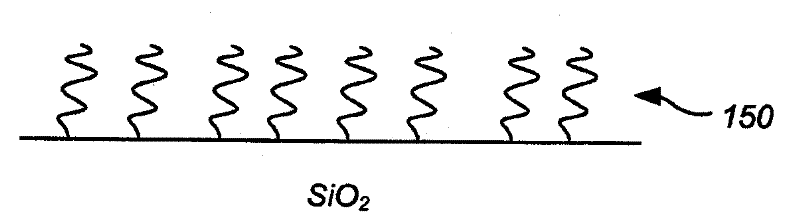

[0027] The fluid ejector 100 includes a substrate 102 having a fluid flow path 104 formed in the substrate. The substrate 102 may include a flow path body 110, a nozzle layer 112 and a diaphragm layer 114. The fluid flow path 104 may include a fluid inlet 120, an ascending part 122, a suction chamber 124 adjacent to the diaphragm layer 114, a descending part 126, and a nozzle 128 formed through the nozzle layer 112. Each of the flow path body 110, the nozzle layer 112, and the diaphragm layer 114 may be silicon, for example, single crystal silicon. In some embodiments, the flow path body 110, the nozzle layer 112, and the diaphragm layer 114 are melt-bonded or silicon-to-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com