Equipment special for disassembling and assembling coal mine underground comprehensive machine equipment

A special equipment and equipment technology, applied in the direction of mining equipment, hoisting equipment braking devices, cranes, etc., can solve the problems of low labor efficiency, large labor input, and difficult realization, etc., to achieve easy disassembly and transportation, and high degree of automation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

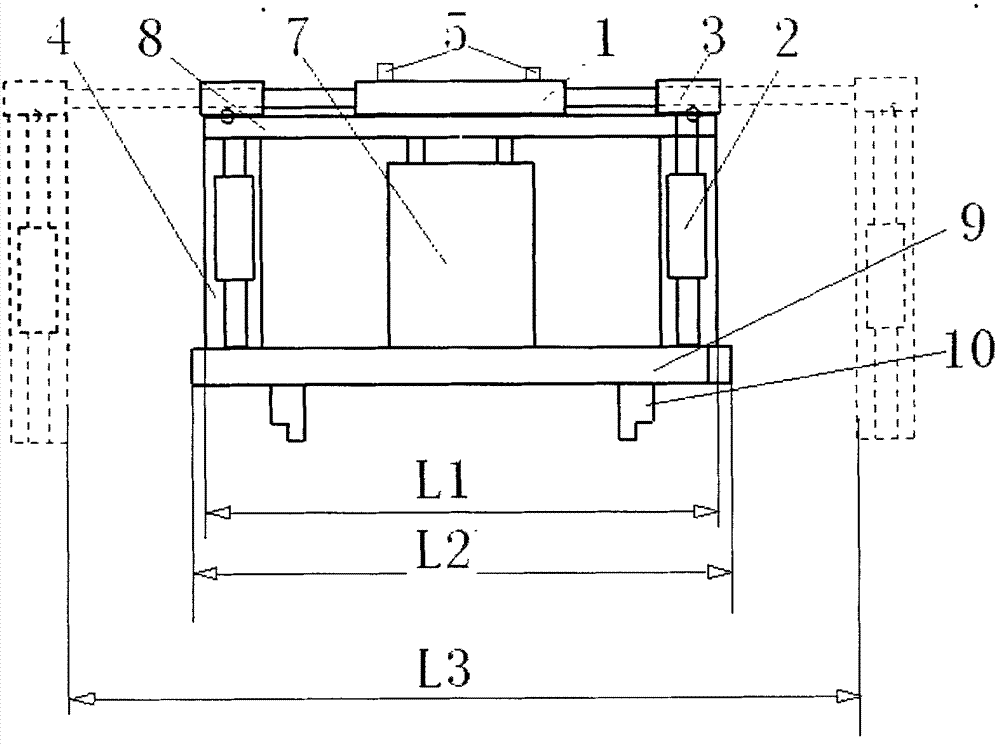

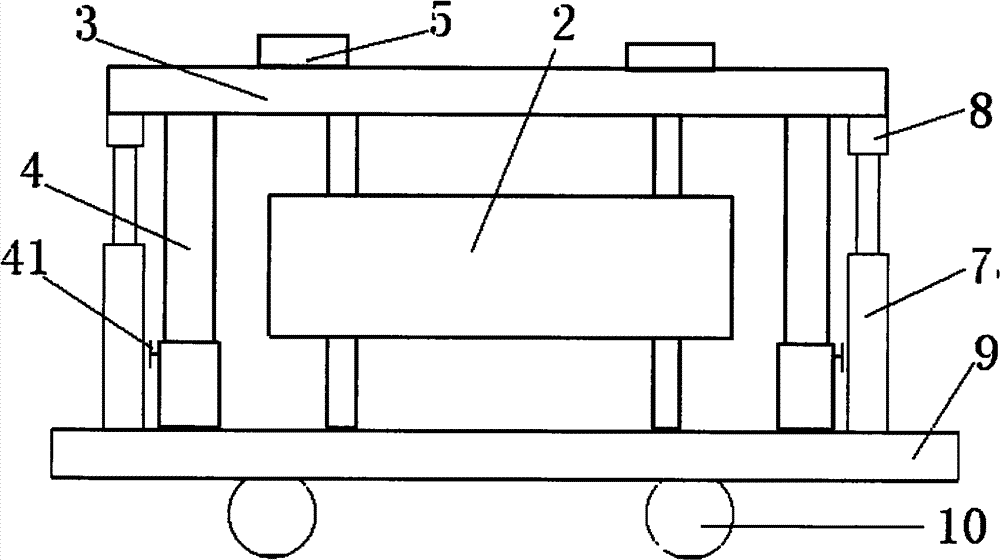

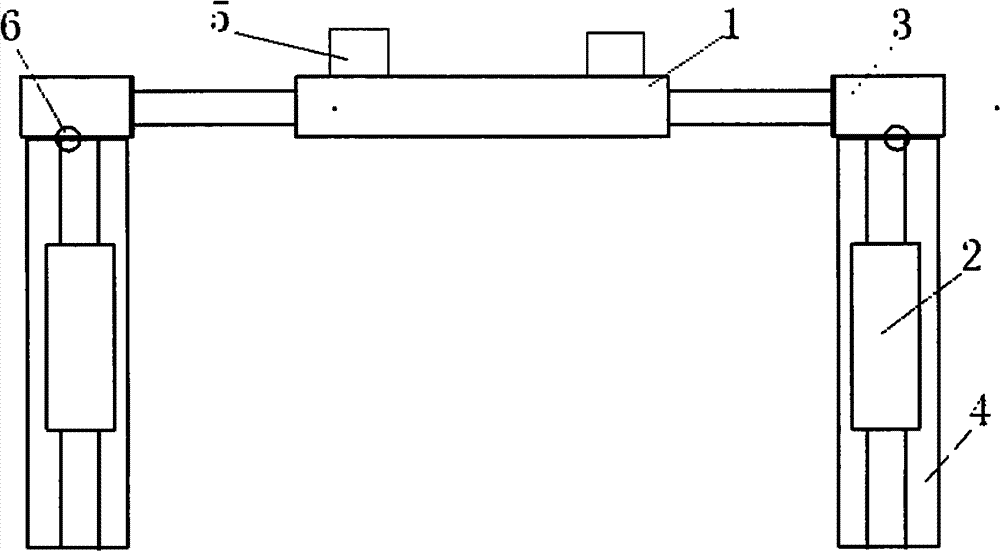

[0034] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 — Figure 4 shown ( figure 1 The dotted line part is the state after the deformed lifting frame is widened and raised), the present invention includes the deformed lifting frame, a special operation vehicle, a hydraulic pump and a control system;

[0035] The deformed lifting frame includes an upper work frame and two side support frames, the upper work frame and the two side support frames are connected by a transition beam 3, the upper work frame is provided with a width adjustment device 1, and the width adjustment The device 1 is connected with the transition beam 3; the side support frame is provided with a height adjustment device 2, and the height adjustment device 2 is connected with the transition beam 3, and the two ends of the side support frame are provided with support columns 4, and the support columns 4 are Sleeve type, and a locking device 41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com