Test method for bonding stress between fiber reinforced plastic bar and concrete

A technology of fiber composite reinforcement and fiber reinforced concrete, which is applied in the direction of measuring, measuring devices, instruments, etc., by measuring the change of optical properties of the material when it is stressed, can solve the problem of low survival rate, discrete large reinforcement and concrete adhesion. Problems such as stress distribution and easy damage of knots, to improve detection accuracy, overcome internal strain distribution, and protect optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

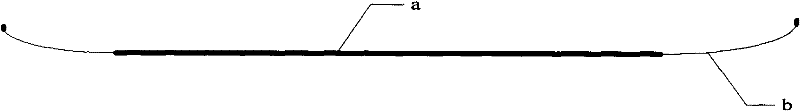

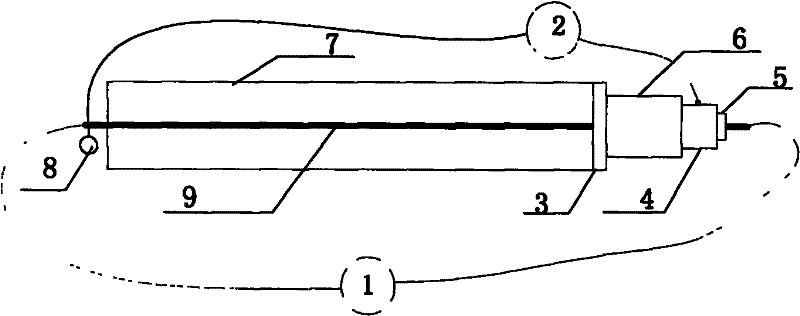

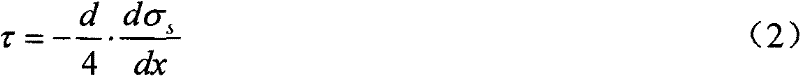

[0023] The design idea of the method for testing the bonding performance of fiber composite reinforced bars (FRP) and concrete provided by the present invention is: to combine the special pultrusion molding process of FRP bars, and arrange the optical fiber b at the center of the bars to form FRP- Optical Fiber Composite Rib (attached figure 1 ), pouring fiber composite reinforcement-optical fiber reinforced concrete bonded specimen 7; using distributed optical fiber sensing technology can realize the advantages of distributed strain detection, and test the FRP tendon stress distribution of the bonded section during the loading process of the bonded specimen Then, the distribution of bond stress can be deduced, so as to realize the accurate measurement of bond stress between FRP bars and concrete, and provide a test method for accurately determining the bond-slip con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com