Insulated wire

A technology for insulating wires and resins, which is applied to insulated cables, insulators, insulated conductors, etc., and can solve problems such as damage and deterioration of insulation coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

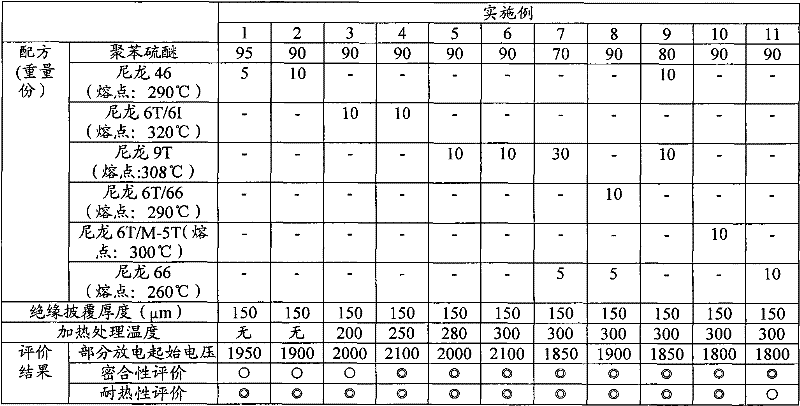

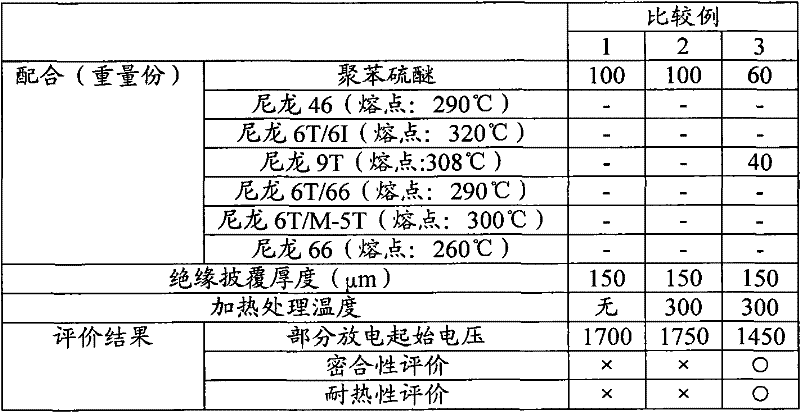

[0034] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto. In addition, the composition of the resin composition constituting the insulating coating of Examples 1 to 11 is shown in Table 1 described later, and the composition of the resin composition constituting the insulating coating of Comparative Examples 1 to 3 is shown in Table 2 described below.

[0035] Preparation of Examples 1-11 and Comparative Examples 1-3

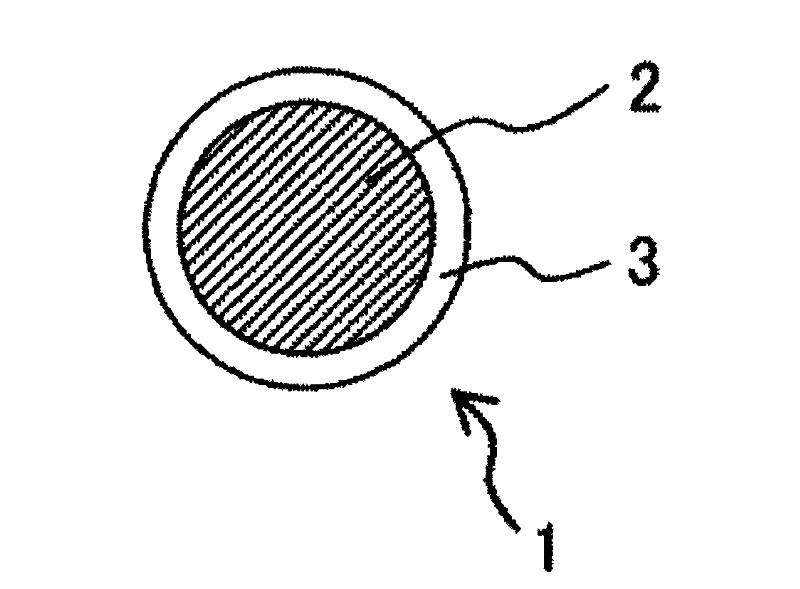

[0036] Use a copper wire with an outer diameter of 1.25mm as a conductor, use an extruder to extrude and coat the resin composition shown in Table 1 and Table 2 on the outer layer of the copper wire, and make the following: figure 1 Insulated wire of the shape shown. The temperature during the extrusion coating was about 300° C., and the thickness of the insulating coating was set to 150 μm. In Examples 3 to 11 and Comparative Examples 2 to 3, heat treatment was performed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com