Assembled center pillar inductor

A technology of inductors and side columns, applied in the field of inductors, can solve the problems of increasing production costs and circuit losses, reducing the service life of inductive devices, increasing copper resistance and copper loss, etc., to save copper, reduce power loss, and spread The effect of magnetic flux reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

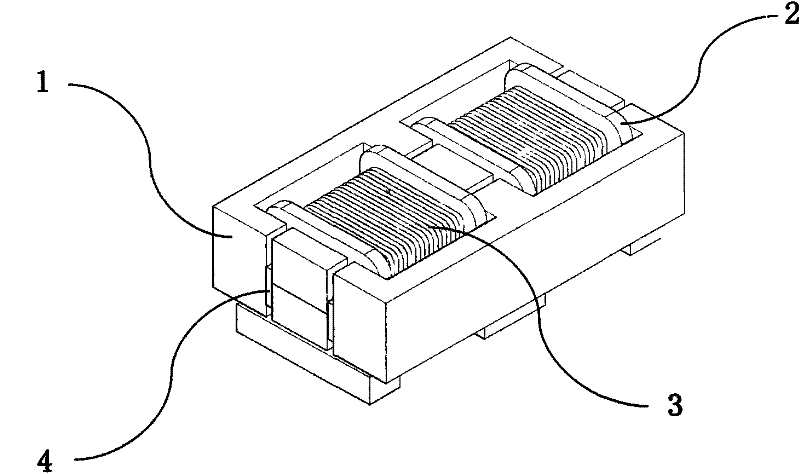

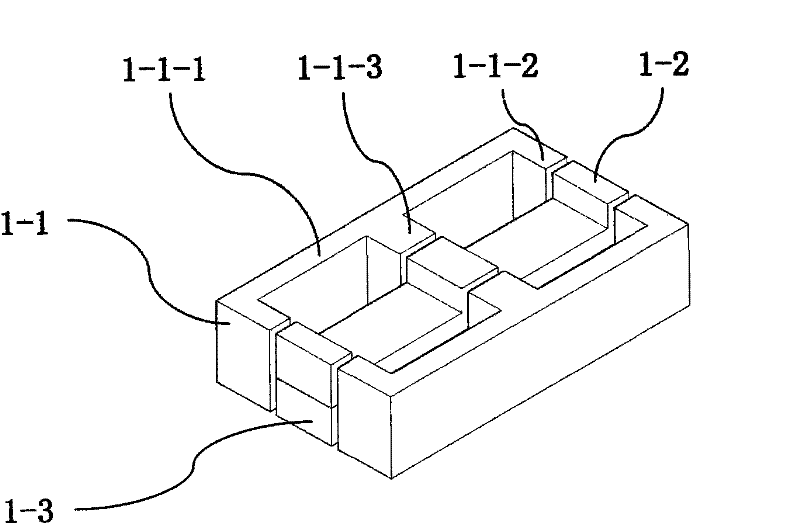

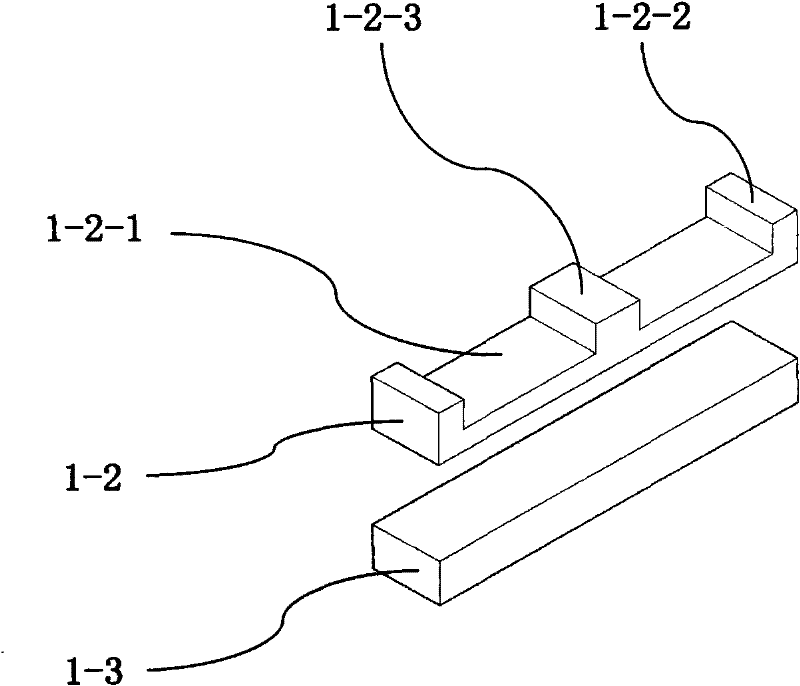

[0027] An embodiment of a combination center column inductor, see Figure 1 to Figure 4 , including a closed magnetic circuit magnetic core body 1, a skeleton 2 and a coil 3, the closed magnetic circuit magnetic core body is composed of a combined central column and two side column magnets 1-1; it is characterized in that the combined central column consists of a card The gear magnet 1-2 is composed of an I-shaped backing magnet 1-3; the clamping magnet is provided with a straight arm 1-2-1, and two end folding arms 1-2-2 are arranged at both ends of the straight arm , at least one middle folding arm 1-2-3 is arranged on the straight arm between the two end folding arms, and all the folding arms are located on the same side of the straight arm; the side column magnet 1-1 is provided with a folding arm; The skeleton is provided with at least two coil winding shafts 2-1, and a through space 2-6 is provided between two adjacent coil winding shafts. The hollow hole 2-4 is located ...

Embodiment 2

[0038] Another application embodiment of a combined central column inductor, see Embodiment 1. The difference from Embodiment 1 is that there is no air-gap medium slot on the edge of the hollow hole of the framework of this embodiment, and the edge is directly placed when assembling. The end face of the folded arm at the end of the column magnet is attached to the side surface of the combined central column, so that the air gap of the magnetic circuit is concentrated between the folded arm of the side column magnet and the side of the combined central column, so that the leakage flux of this embodiment can be reduced to Minimum value for best EMC performance.

Embodiment 3

[0040] Another application embodiment of a combined central column inductor, see Embodiment 1. The difference from Embodiment 1 is that the head end and tail end of the two coils are led out separately to form four circuit access points.

[0041] This embodiment can be used as a common-mode differential-mode integrated inductor in a circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com