High density integrated circuit module structure

An integrated circuit and module structure technology, which is applied to circuits, electrical components, electrical solid devices, etc., can solve the problems of inapplicability, poor heat dissipation of the integrated circuit module structure 100, and reduced manufacturing costs, and achieves a simple, convenient and good assembly process. The effect of signal transmission quality, lower manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, features and functions of the present invention more comprehensible, the present invention will be described in detail with reference to the following embodiments and accompanying drawings.

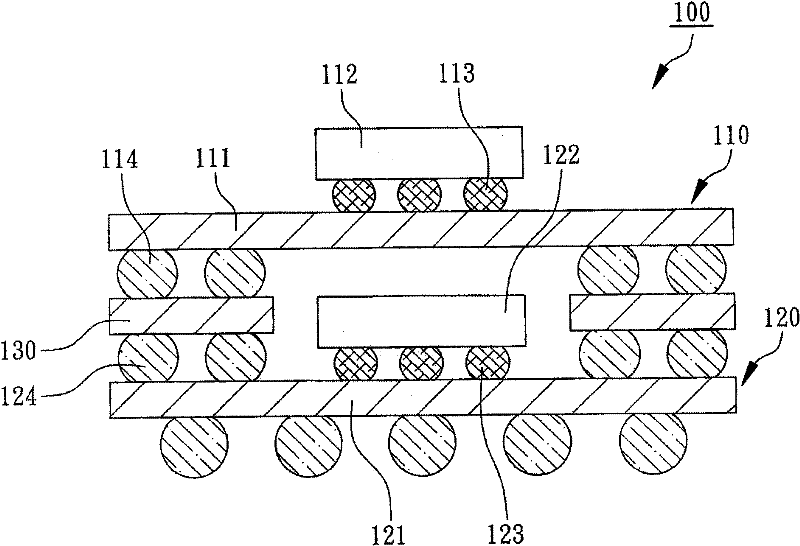

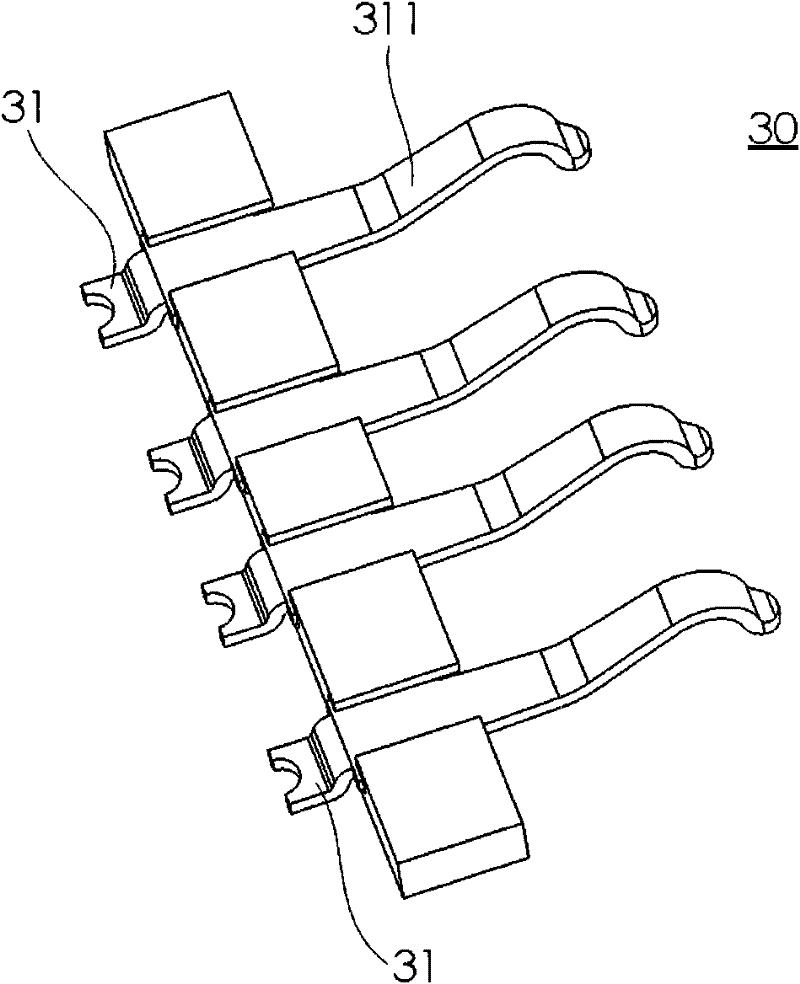

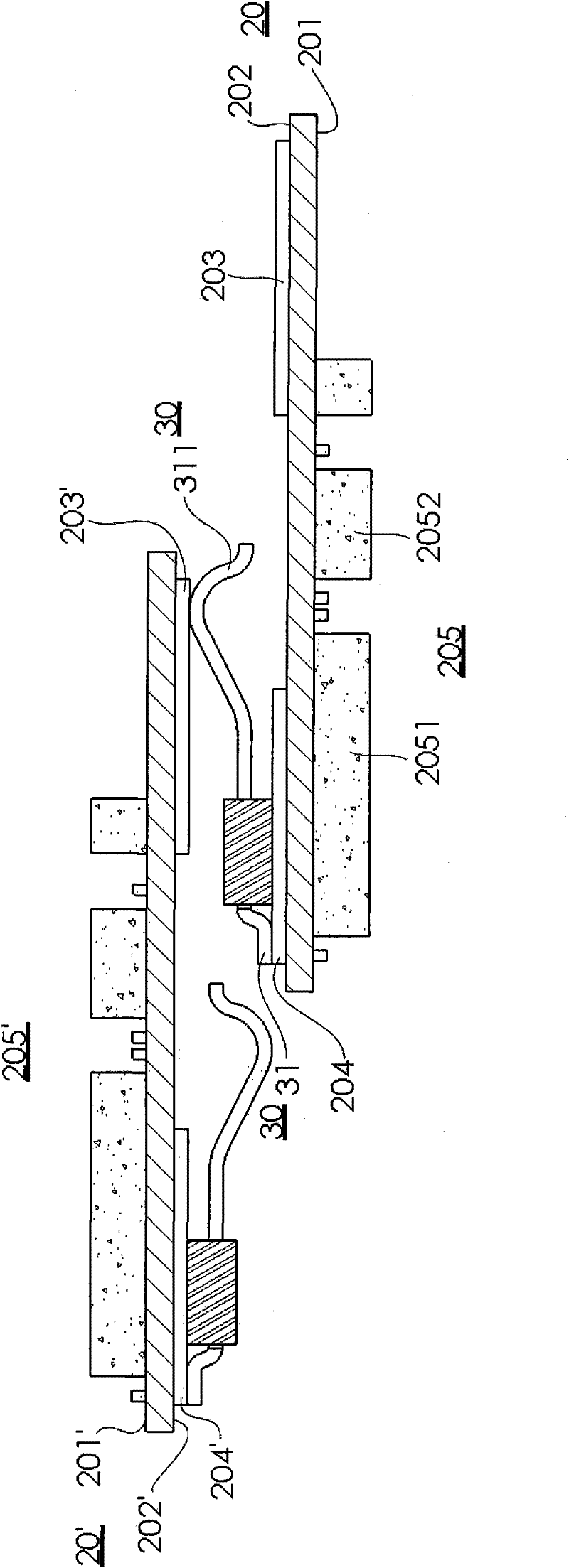

[0032] Such as figure 2 , image 3As shown, it is a high-density integrated circuit module structure provided by the present invention, which mainly includes at least one substrate 20 and at least one heat dissipation element 30 . The substrate 20 is used as a chip carrier and a transfer interface. It has an inner surface 201 and an outer surface 202 . It may be a high-density double-sided multilayer printed circuit board with circuits (not shown) formed inside. Wherein, the outer surface 202 has a plurality of outer contact pads 203 and a plurality of transfer contact pads 204, wherein the outer contact pads 203 and the transfer contact pads 204 are arranged in reverse symmetry, and the outer contact pads 203 pass through the circuit on the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com