Clamp for coupling welding light-emitting device

A technology of light emitting devices and fixtures, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of large changes in product indicators, poor consistency of new device performance, non-parallel, etc., to ensure the quality of coupling welding and improve work. Efficiency, effect of shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing and specific implementation;

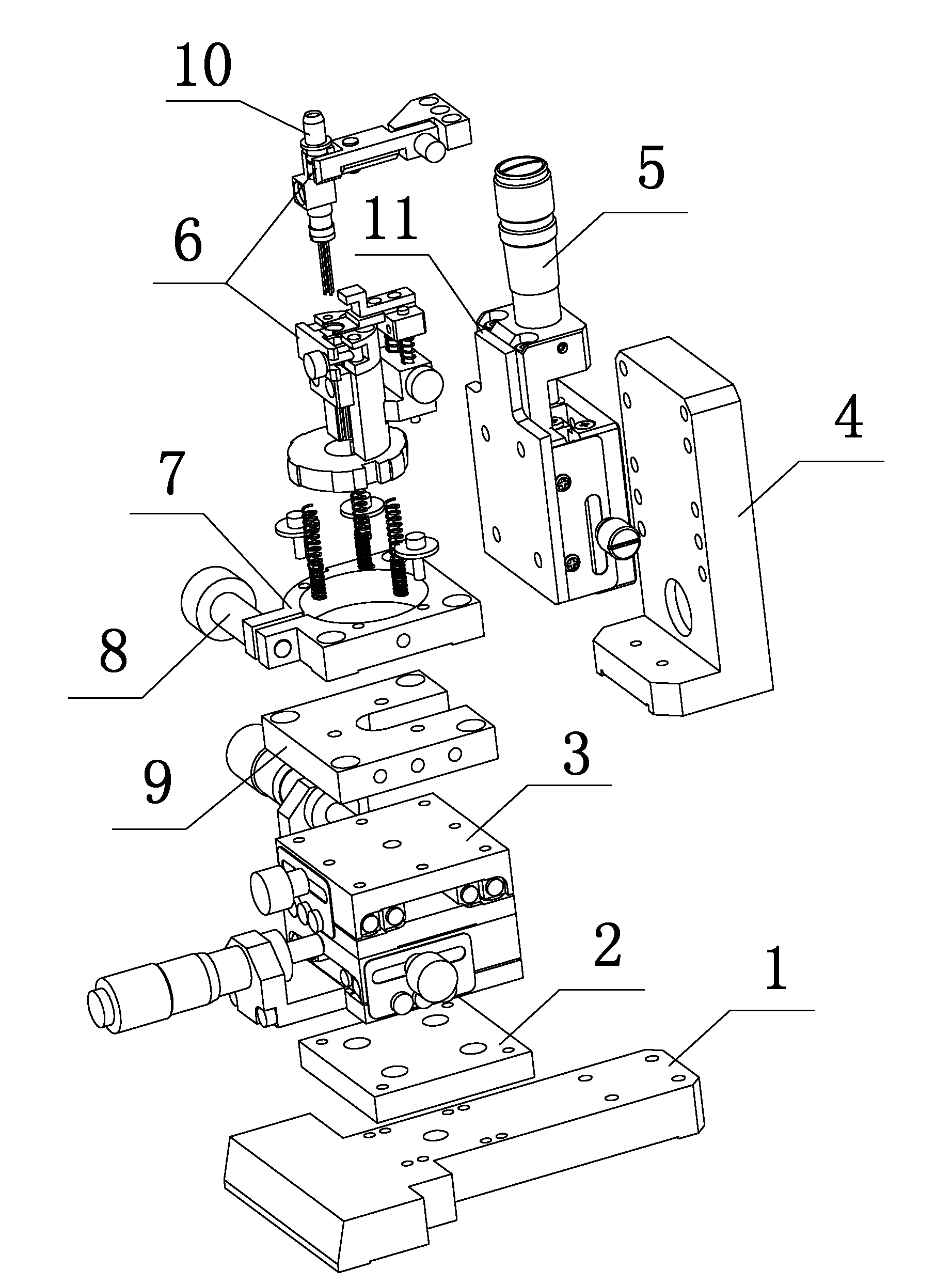

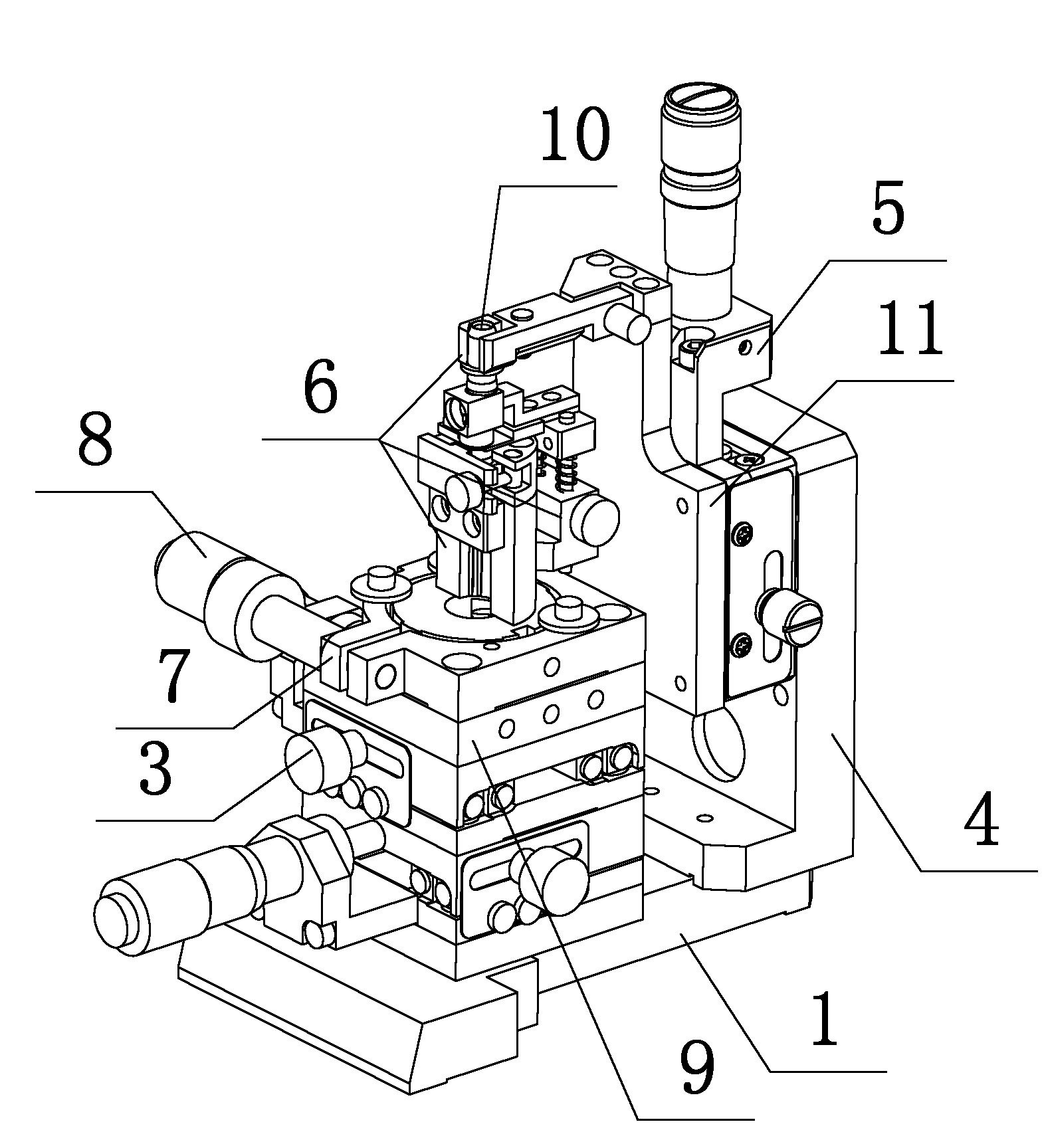

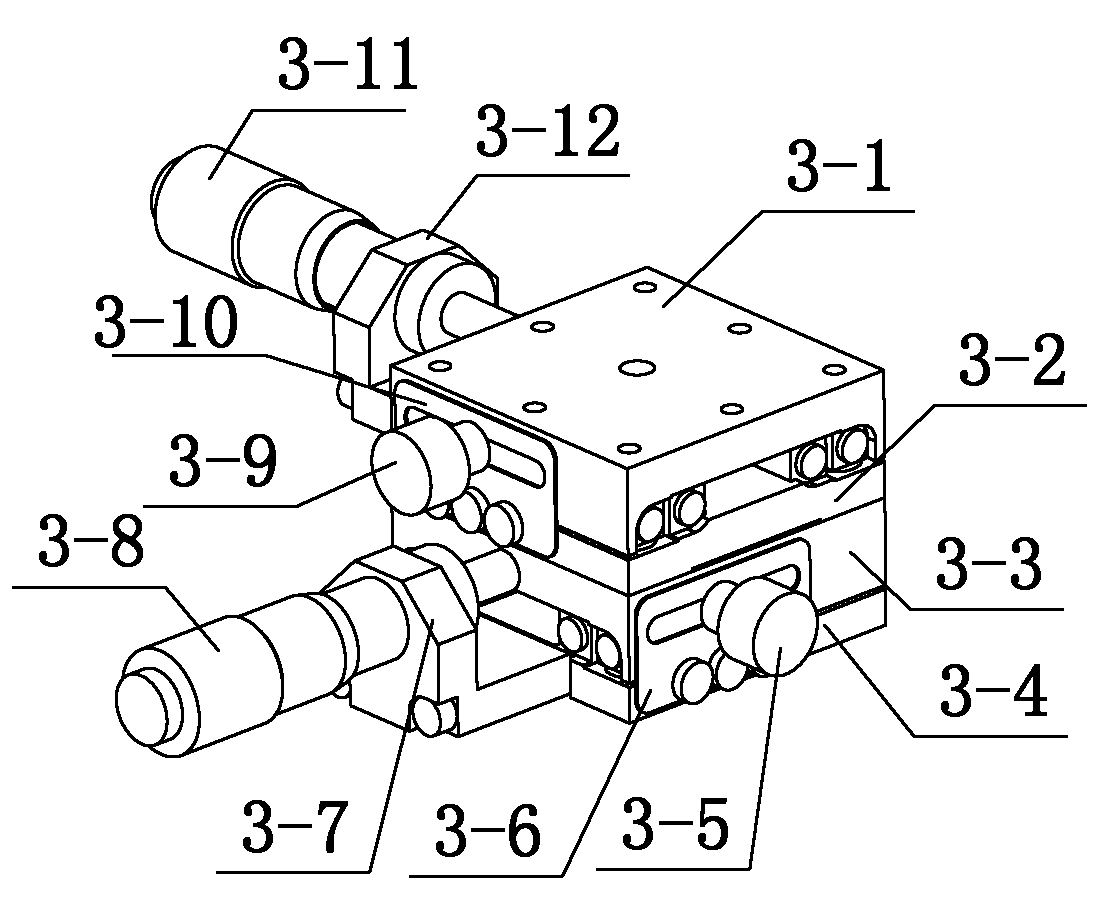

[0045] see Figure 1 to Figure 3 , a fixture for coupling welding of light-emitting devices, including a base plate 1, and also includes an XY horizontal moving platform 3, a Z sliding platform 5 and a clamping device 6, and the XY horizontal moving platform 3 is composed of an X horizontal moving platform, a Y horizontal The mobile platform consists of an X horizontal mobile platform and a Y horizontal mobile platform integrated; the XY horizontal mobile platform 3 is located above the bottom plate 1, and an adapter plate A2 is arranged between the XY horizontal mobile platform 3 and the bottom plate 1 . The X horizontal moving platform is provided with an X-direction fine-tuning screw A3-11 and a locking screw B3-5; the Y-direction moving platform is provided with a Y-direction fine-tuning screw B3-8 and a locking screw A3-9. The X horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com