Hydrogen selective oxidation catalyst used in the propane dehydrogenation process and preparation method thereof

An oxidation catalyst and propane dehydrogenation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as low oxygen conversion rate and high hydrocarbon consumption , to achieve high oxygen conversion rate, low hydrocarbon loss rate and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

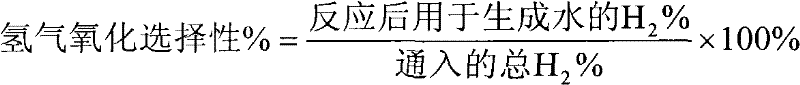

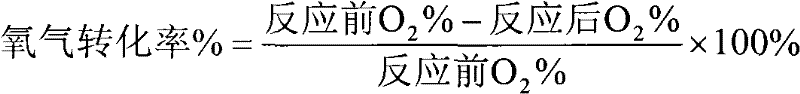

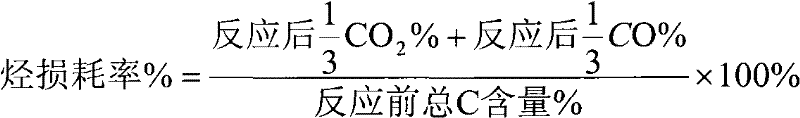

Embodiment 1

[0026] Weigh 2 grams over a surface of 50 meters 2 / g, nano-Al with a pore size of 29 nm 2 o 3 Carrier, add 10 ml of deionized water, pipette 0.18 ml of H 2 PtCl 6 solution and 1.44 ml of LiNO 3 solution, add dropwise 0.022 g of SnCl 4 Solution, adjust the pH value of the solution to 1.5 with 2.5% ammonia water, then soak in a water bath at 80°C for 1 hour, take out the sample and filter it, dry it in an oven at 120°C for 8 hours, and then put the sample in a muffle furnace at 550°C ℃ for 4 hours to obtain the desired catalyst. The prepared catalyst was loaded into a fixed-bed reactor, and the activity evaluation was carried out at 550°C. The results were as follows: the selectivity of hydrogen in the process was 62%, the conversion rate of oxygen was 98.1%, and the loss rate of hydrocarbon was 0.9%. .

Embodiment 2

[0028] Weigh 2 grams over a surface of 50 meters 2 / g, nano-Al with a pore size of 29 nm 2 o 3 Carrier, add 10 ml of deionized water, pipette 0.88 ml of H 2 PtCl 6 solution and 7.2 ml of LiNO 3 solution, add dropwise 0.0439 g of SnCl 4 Solution, adjust the pH value of the solution to 1.5 with 2.5% ammonia water, then soak in a water bath at 80°C for 1 hour, take out the sample and filter it, dry it in an oven at 120°C for 8 hours, and then put the sample in a muffle furnace at 550°C ℃ for 4 hours to obtain the desired catalyst. The prepared catalyst was loaded into a fixed-bed reactor, and the activity evaluation was carried out at 550°C. The results were as follows: the selectivity of hydrogen in the process was 86%, the conversion rate of oxygen was 98.5%, and the loss rate of hydrocarbon was 0.7%. .

Embodiment 3

[0030] Weigh 2 grams over a surface of 50 meters 2 / g, nano-Al with a pore size of 29 nm 2 o 3 Carrier, add 10 ml of deionized water, pipette 0.88 ml of H 2 PtCl 6 solution and 7.2 ml of LiNO 3 solution, add dropwise 0.2195 g of SnCl 4Solution, adjust the pH value of the solution to 1.5 with 2.5% ammonia water, then soak in a water bath at 80°C for 1 hour, take out the sample and filter it, dry it in an oven at 120°C for 8 hours, and then put the sample in a muffle furnace at 550°C ℃ for 4 hours to obtain the desired catalyst. The prepared catalyst was loaded into a fixed-bed reactor, and the activity evaluation was carried out at 550°C. The results were as follows: in the process, the selectivity of hydrogen was 81%, the conversion rate of oxygen was 98.2%, and the loss rate of hydrocarbon was 0.7%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com