High-precision desulfurization and denitrification catalyst carrier and preparation method thereof

A denitrification catalyst, high-precision technology, applied in the direction of catalyst carrier, molecular sieve catalyst, chemical instrument and method, etc., can solve the problem of low desulfurization and denitrification efficiency of the catalyst, achieve excellent ion exchange capacity, suppress surface area carbon velocity, reduce surface area The effect of acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

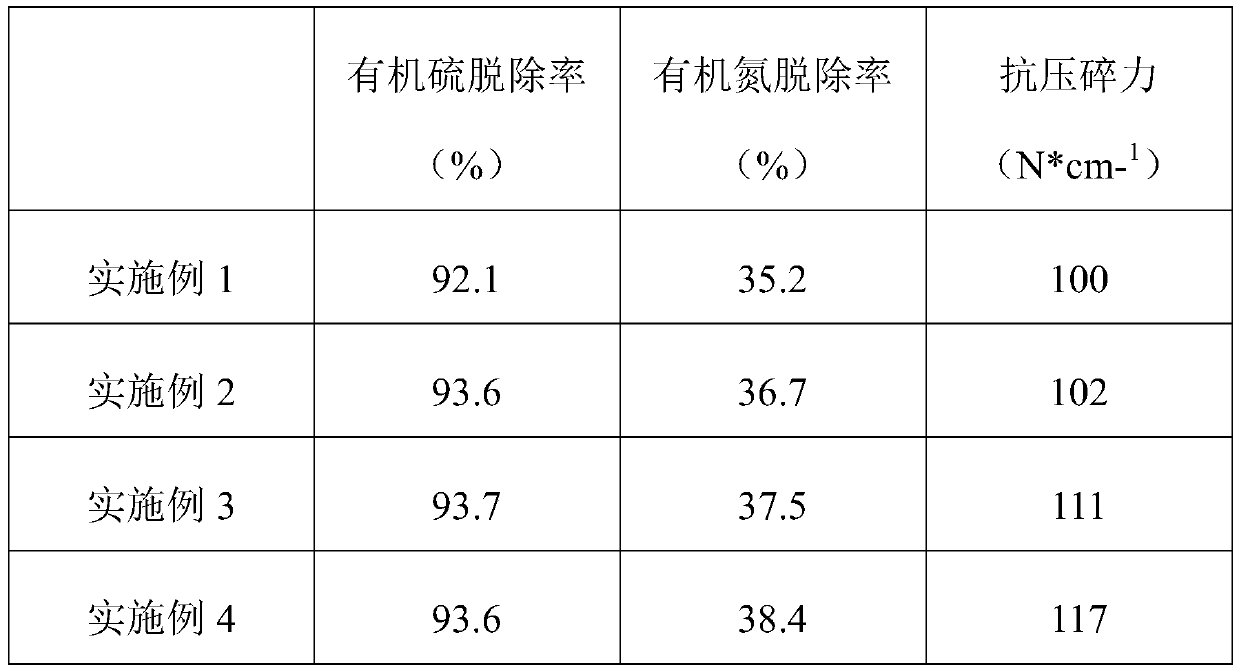

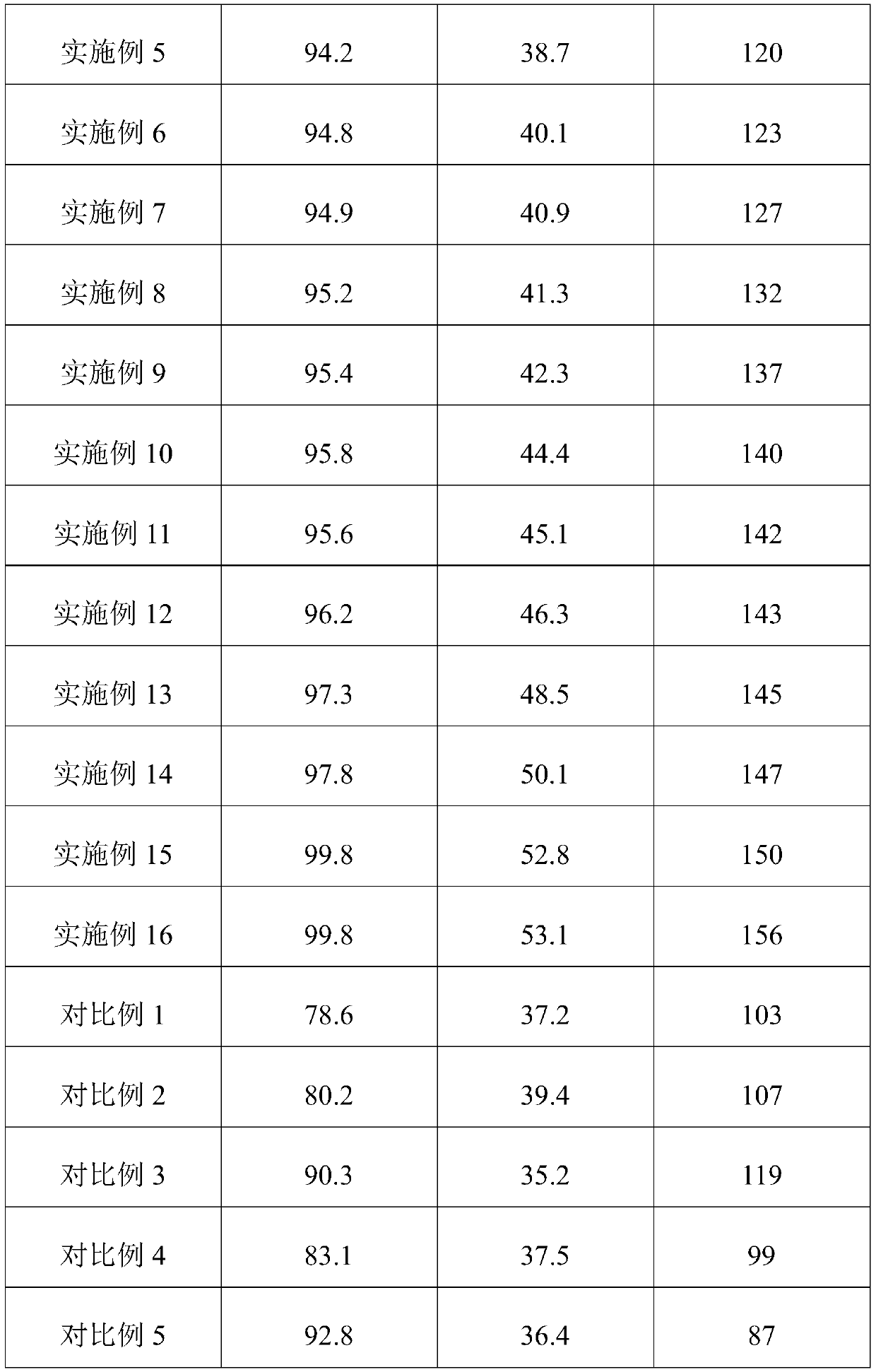

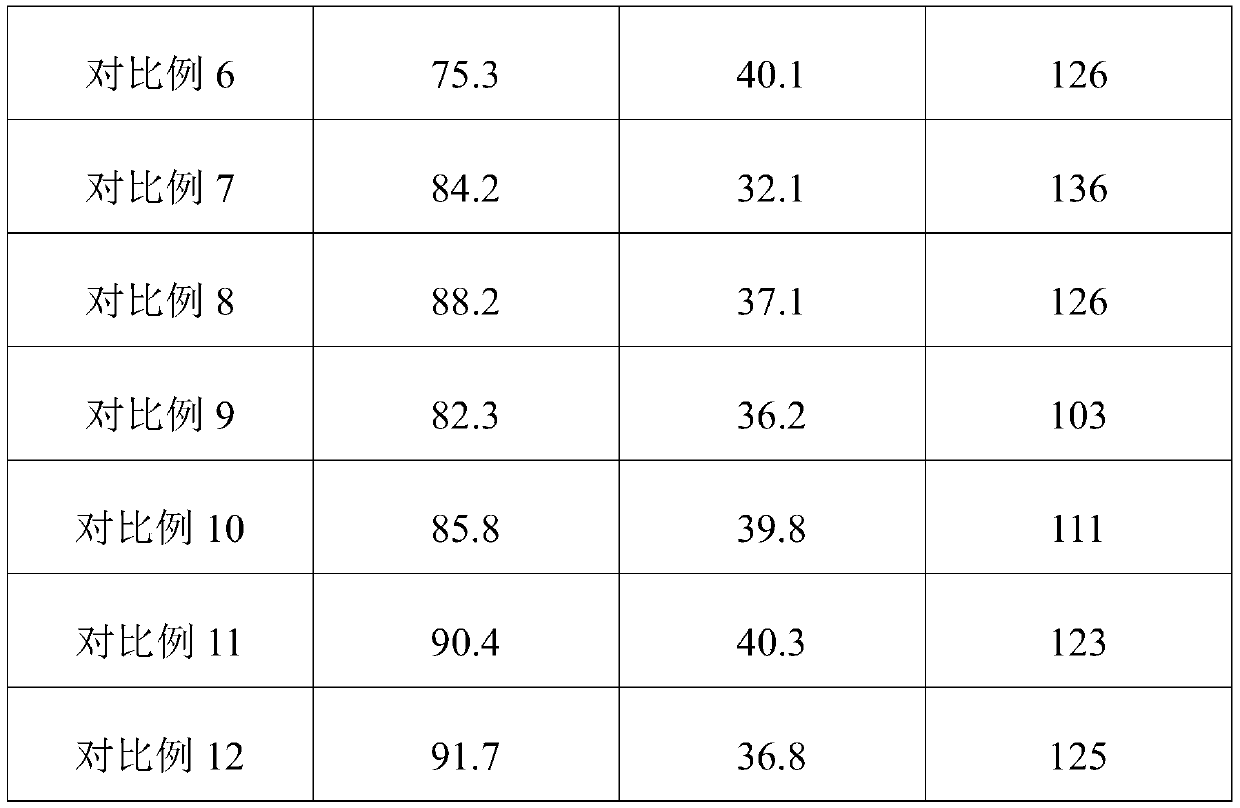

Examples

Embodiment 1

[0026] The high-precision desulfurization and denitrification catalyst carrier described in this embodiment includes the following components:

[0027] Magnesium oxide 10kg, zirconia 10kg, MCM-22 molecular sieve 0.1kg, silicon oxide 35kg, aluminum oxide 35kg.

[0028] This embodiment also provides a method for preparing the above-mentioned high-precision desulfurization and denitrification catalyst carrier, including the following steps:

[0029] (1) Take the silicon oxide, aluminum oxide, magnesium oxide and MCM-22 molecular sieve according to the selected weight and carry out dry mixing for 0.5 hours, and mix well, and set aside;

[0030] (2) Add water to the zirconium salt taken according to the selected weight to prepare an aqueous solution of zirconium salt, then take the mixture obtained in step (1), and add 8% silica sol accounting for the weight of the mixture into the aqueous solution of zirconium salt Carry out wet mixing for 2.5 hours, and mix well, set aside;

[...

Embodiment 2

[0033] The high-precision desulfurization and denitrification catalyst carrier described in this embodiment includes the following components:

[0034] Magnesium oxide 20kg, zirconium oxide 0.1kg, MCM-22 molecular sieve 10kg, silicon oxide 45kg, aluminum oxide 45kg.

[0035] This embodiment also provides a method for preparing the above-mentioned high-precision desulfurization and denitrification catalyst carrier, including the following steps:

[0036] (1) Take the silicon oxide, aluminum oxide, magnesium oxide and MCM-22 molecular sieve according to the selected weight and carry out dry mixing for 2.5 hours, and mix well, and set aside;

[0037] (2) Add water to the zirconium salt taken according to the selected weight to prepare an aqueous zirconium salt solution, then take the mixture obtained in step (1), account for 8% attapulgite by weight of the mixture, and add the zirconium salt aqueous solution wet mixing for 0.5 hours, and mix evenly, set aside;

[0038] (3) Extrud...

Embodiment 3

[0040] The high-precision desulfurization and denitrification catalyst carrier described in this embodiment includes the following components:

[0041] Magnesium oxide 15kg, zirconia 5kg, MCM-22 molecular sieve 5kg, silicon oxide 40kg, aluminum oxide 40kg.

[0042] This embodiment also provides a method for preparing the above-mentioned high-precision desulfurization and denitrification catalyst carrier, including the following steps:

[0043] (1) The silicon oxide, pseudo-boehmite, activated magnesia and MCM-22 molecular sieve are weighed according to the selected weight and dry-mixed for 1 hour, and mixed evenly, and set aside;

[0044] (2) Add water that is 1 time the weight of the zirconium nitrate to the zirconium nitrate weighed according to the selected weight to prepare an aqueous solution of zirconium salt, then take the mixture obtained in step (1), accounting for 3% of the weight of the mixture The silica sol was added into the zirconium salt aqueous solution for w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com