Method for preparing lactide from lactic acid

A lactide and lactic acid technology, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve the problems of harsh reaction conditions and complicated process flow, and achieve the effect of simple equipment, high reactivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

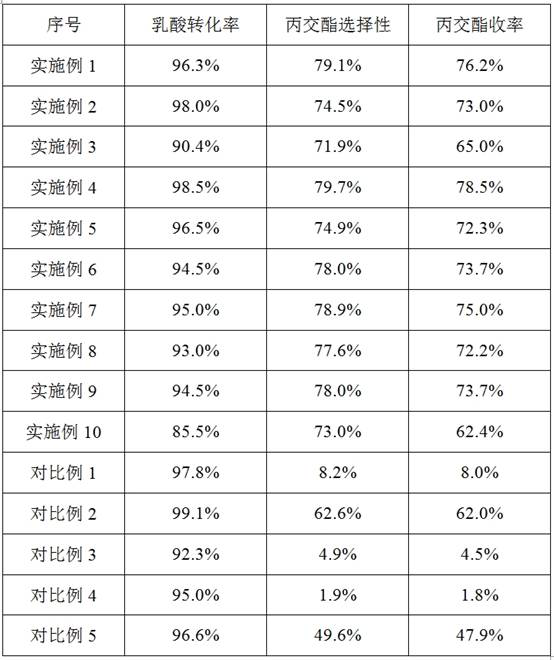

Examples

Embodiment 1

[0033] (1) According to the molar ratio of silica sol: sodium hydroxide: tetraethylammonium hydroxide: water, each component is 1:0.3:0.25:100, mix each component to prepare Si-Beta mother liquor, and then press molecular sieve and silica sol ( SiO 2 content meter) the molar ratio is 10:1, add H-Beta molecular sieve (particle size is about 500nm, SiO 2 / Al 2 O 3 = 15), stand at 150°C for 48h crystallization, filter and separate after crystallization, wash with deionized water until neutral, dry at 100°C for 12h, calcinate at 550°C for 5h to obtain Si-Beta / H-Beta core-shell molecular sieve catalyst . In the prepared catalyst, the H-Beta content was 91.9% and the Si-Beta content was 8.1% by mass.

[0034] (2) According to the mass ratio of Si-Beta / H-Beta core-shell molecular sieve and lactic acid is 1:2, and the solid-liquid ratio of Si-Beta / H-Beta core-shell molecular sieve and toluene is 1:20 (g:mL), the catalyst , L-lactic acid with a mass concentration of 80%, and toluen...

Embodiment 2

[0036] (1) Mix the components uniformly according to the molar ratio of ethyl orthosilicate: sodium hydroxide: tetraethyl ammonium hydroxide: water: 1:0.2:0.25:80, and then press molecular sieve and silica sol (with SiO 2 content) in a molar ratio of 10:1, add H-Beta molecular sieve (particle size is about 200nm, SiO 2 / Al 2 O 3 =10), stand at 140°C for 24h crystallization, filter and separate after crystallization, wash with deionized water until neutral, dry at 100°C for 12h, calcinate at 550°C for 5h to obtain Si-Beta / H-Beta core-shell molecular sieve catalyst . In the prepared core-shell catalyst, the H-Beta content was 92.6% and the Si-Beta content was 7.4% by mass.

[0037] (2) According to the mass ratio of Si-Beta / H-Beta core-shell molecular sieve and lactic acid is 1:1, and the solid-liquid ratio of Si-Beta / H-Beta core-shell molecular sieve and toluene is 1:10 (g:mL), the catalyst , L-lactic acid with a mass concentration of 80%, and toluene were mixed, and the r...

Embodiment 3

[0039] (1) Mix the components uniformly according to the molar ratio of silica: sodium hydroxide: tetraethylammonium hydroxide: water to 1:0.4:0.4:120, and then press molecular sieve and silica sol (SiO 2 Content calculation) the molar ratio is 20:1, add H-Beta molecular sieve (particle size is about 2μm, SiO 2 / Al 2 O 3 =40), stand at 160°C for 72h crystallization, filter and separate after crystallization, the product particles are washed with deionized water until neutral, dried at 100°C for 12h, and calcined at 550°C for 5h to obtain Si-Beta / H-Beta core-shell Molecular sieve catalyst. In the prepared core-shell catalyst, the H-Beta content is 95.5% and the Si-Beta content is 4.5% by mass.

[0040] (2) According to the mass ratio of Si-Beta / H-Beta core-shell molecular sieve and lactic acid is 1:3, and the solid-liquid ratio of Si-Beta / H-Beta core-shell molecular sieve and toluene is 1:30 (g:mL), the catalyst , L-lactic acid with a mass concentration of 80%, and toluene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com