Catalyst for preparing low-carbon olefin through Fischer-Tropsch synthesis and preparation method of catalyst

A low-carbon olefin, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve low-carbon olefin selectivity, CO conversion, etc. It can improve the conversion rate, reduce the acidity, and achieve the effect of large pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

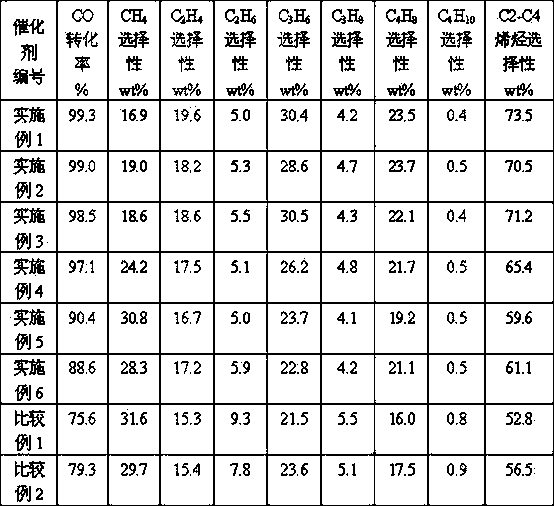

Examples

Embodiment 1

[0028] Mix titanium oxide and α-alumina powder evenly, press tablet and sieve into 60-80 mesh to prepare composite carrier H; dissolve the required amount of ferric nitrate, manganese nitrate, magnesium nitrate, and potassium nitrate in water to make a mixed Solution I; under the condition of vacuum degree of 10kPa, impregnate the above mixed solution I on the required amount of the prepared composite carrier H to obtain the catalyst precursor J; the impregnated catalyst precursor J is dried at 110°C, Then it is calcined at a temperature of 550° C. for 2 hours to obtain a catalyst for Fischer-Tropsch synthesis of low-carbon olefins. The weight of the active component and the composite oxide carrier in the catalyst is 20% and 80% respectively, the weight ratio of titanium oxide and α-alumina in the composite oxide carrier, and the general composition formula of the atomic ratio of the active component is as follows:

[0029] 20% Fe 100 mn 50 Mg 5 K 5 o x +80%(10%TiO 2 +90...

Embodiment 2

[0033] Mix titanium oxide and α-alumina powder evenly, press tablet and sieve into 60-80 mesh to prepare composite carrier H; dissolve the required amount of ferric nitrate, manganese nitrate, magnesium nitrate, and potassium nitrate in water to make a mixed Solution I; under the condition of vacuum degree of 10kPa, impregnate the above mixed solution I on the required amount of the prepared composite carrier H to obtain the catalyst precursor J; the impregnated catalyst precursor J is dried at 110°C, Then it is calcined at a temperature of 550° C. for 2 hours to obtain a catalyst for Fischer-Tropsch synthesis of low-carbon olefins. The weights of the active component and the composite oxide carrier in the catalyst are 40% and 60% respectively, the weight ratio of titanium oxide and α-alumina in the composite oxide carrier, and the general composition formula of the atomic ratio of the active component are as follows:

[0034] 40% Fe 100 mn 40 Ca 10 K 10 o x +60%(10%TiO ...

Embodiment 3

[0038] Mix titanium oxide and α-alumina powder evenly, press tablet and sieve into 60-80 mesh to prepare composite carrier H; dissolve the required amount of ferric nitrate, manganese nitrate, magnesium nitrate, and potassium nitrate in water to make a mixed Solution I; under the condition of vacuum degree of 10kPa, impregnate the above mixed solution I on the required amount of the prepared composite carrier H to obtain the catalyst precursor J; the impregnated catalyst precursor J is dried at 110°C, Then it is calcined at a temperature of 550° C. for 2 hours to obtain a catalyst for Fischer-Tropsch synthesis of low-carbon olefins. The weight of the active component and the composite oxide carrier in the catalyst is 50% and 50% respectively, the weight ratio of titanium oxide and α-alumina in the composite oxide carrier, and the general composition formula of the atomic ratio of the active component is as follows:

[0039] 50% Fe 100 mn 20 Mg 15 Cs 15 o x +50% (50%TiO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com