High-magnetic-field-intensity pipeline deironing device capable of cleaning automatically

A magnetic field strength, automatic cleaning technology, applied in the direction of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of weakened iron removal effect, reduced iron removal efficiency, low magnetic field strength, etc., to achieve good iron removal effect and use The effect of long life and high magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

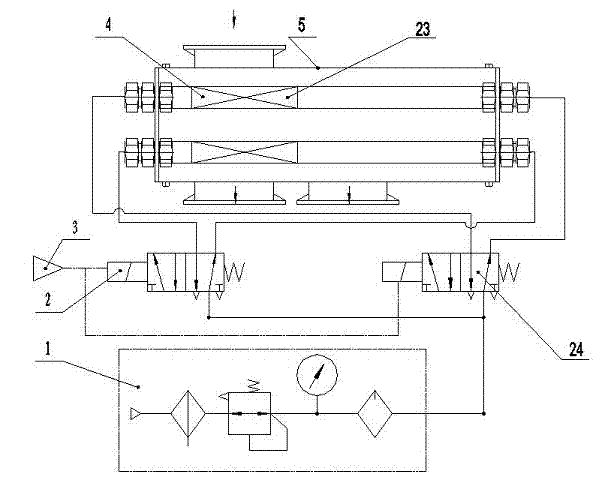

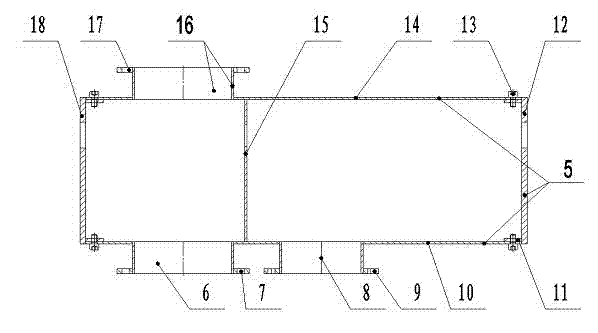

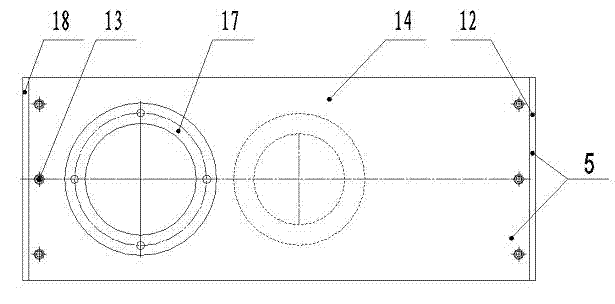

[0016] From Figure 1-Figure 6It can be seen from the figure that: a high magnetic field strength self-cleaning pipeline iron remover is characterized in that: the high magnetic field strength self-cleaning pipeline iron remover is mainly composed of a box body 5, a magnet device, a pneumatic device and an electric control device 3, the The box body 5 is rectangular and is made of stainless steel plate. Its upper side panel 14, lower side panel 10 and front and rear side panels are welded into one after bending stainless steel sheets, and the upper side panel 14 and the lower side panel The left and right ends of 10 are evenly distributed to offer bolt through holes respectively, and the upper and lower ends of the left and right end panels 18,12 inner surfaces are respectively welded elongated mounting plates 11, and on each mounting plate 11 corresponding to the upper and lower The positions of the bolt through holes on the side panels 14, 10 are respectively provided with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com