Production technology of high-phosphorus iron casting

A production process and iron casting technology, which is applied in the production process field of low-alloy gray iron castings, can solve the problems of high production cost and poor mechanical properties of high-phosphorus cast iron, and achieve the effect of avoiding cold cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to adapt to the development of high-strength and high-rigidity machine tool casting materials, further improve the wear resistance and performance of the machine tool, and take into account the cost of local raw materials, the basic process idea of the present invention is to adopt a production method close to synthetic cast iron, namely The addition ratio of scrap steel has been greatly increased, and the addition ratio of pig iron has been reduced. The pig iron here is to adopt 18# ordinary pig iron.

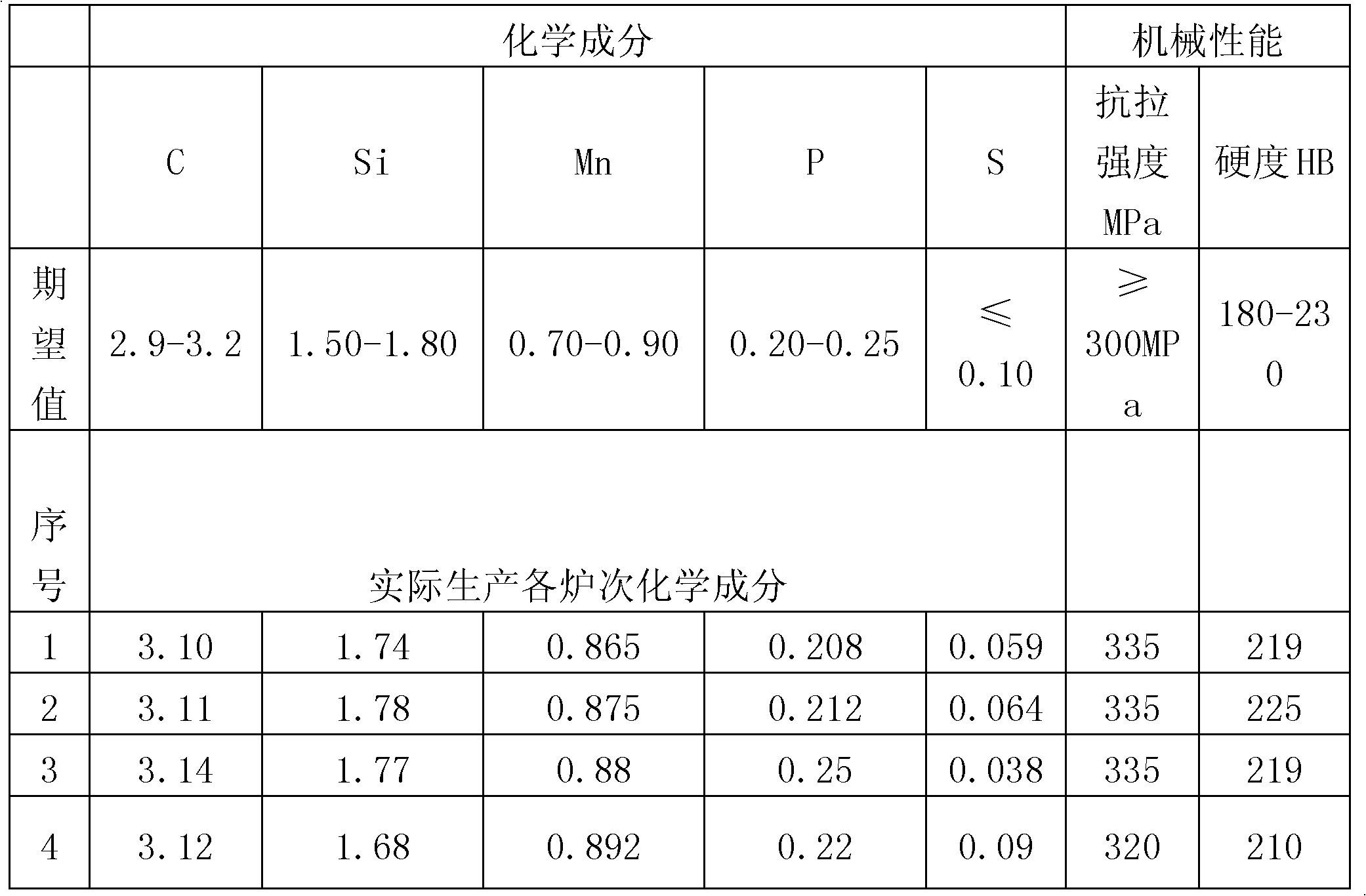

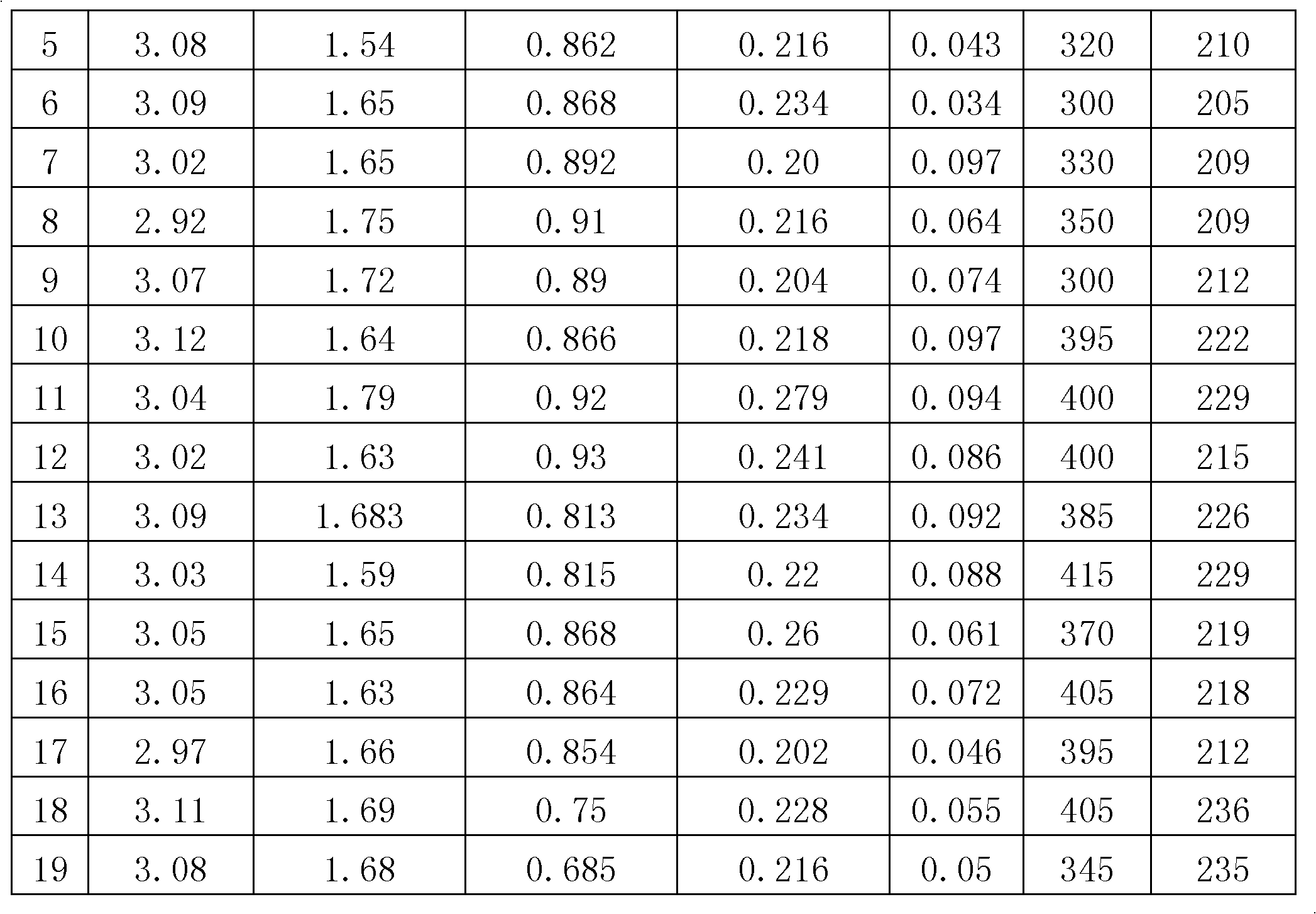

[0029] The following table 1 compares the component distribution ratio of the charge of the present invention with the specific example of the traditional scheme.

[0030] Table 1

[0031] charge

pig iron

scrap steel

Return charge

Carburizer

Ferrophosphorus

traditional solution

6

1.5

2

0

0.25

0.10

0.15

this invention

1.0-1.8

5.3-6.2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com