Machine housing of a hydraulic machine

A technology of fluid machinery and casing, which is applied in the field of casing of fluid machinery, and can solve problems such as wrong assembly and damage of the casing cover, and achieve the effects of low measurement cost, simple manufacturing, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

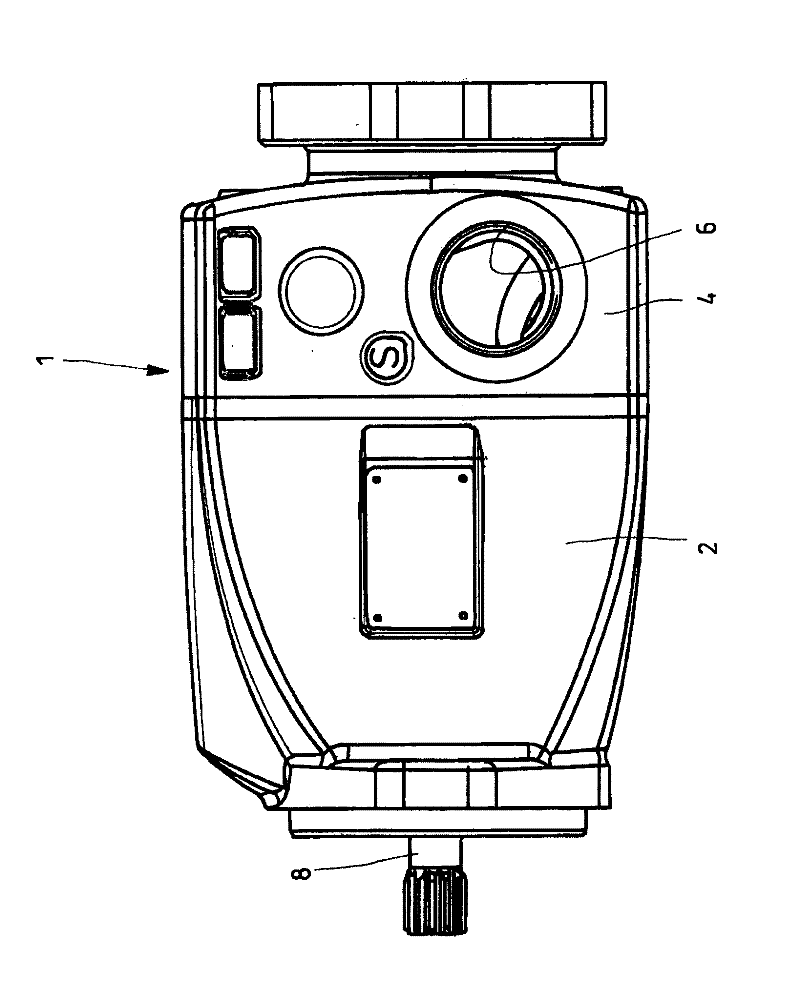

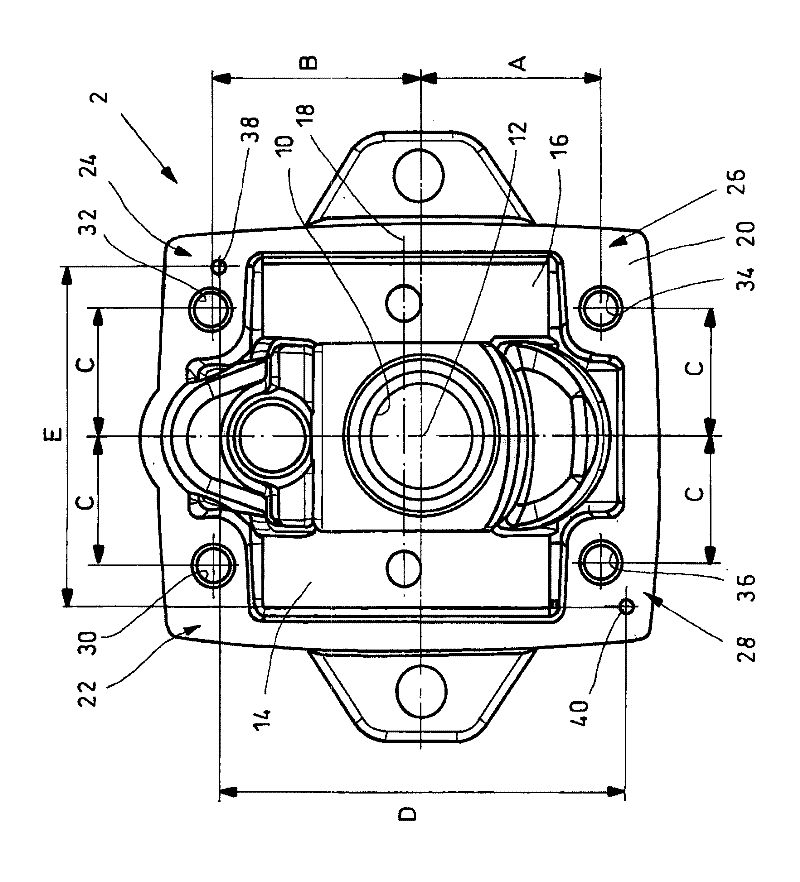

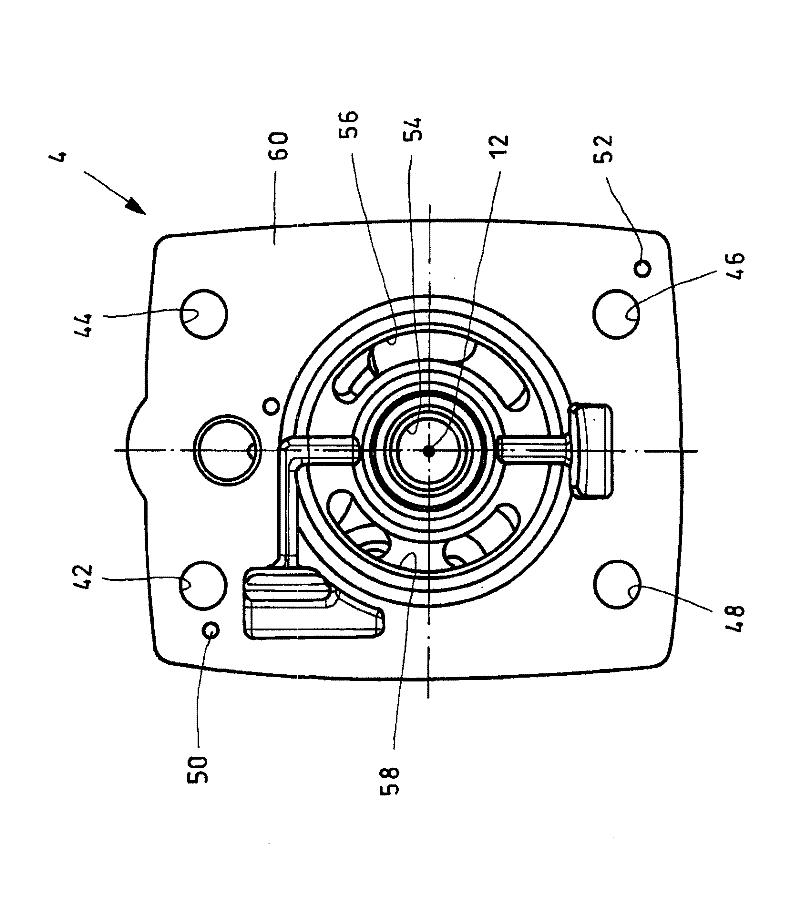

[0018] figure 1 An exemplary embodiment of the housing 1 of the fluid machine according to the invention is shown in side view. Fluid machinery involves a swash plate type axial piston machine which is used as a hydraulic pump. The housing 1 has a housing section 2 and a web 4 fastened thereto, which closes the housing section 2 in a sealing manner. The connection plate 4 has connection holes on the opposite side surfaces respectively, wherein figure 1 The connecting hole marked with reference numeral 6 is shown in . In this case, one connection hole is used as a pressure line connection, while the other connection hole is used as a suction connection for a hydraulic pump. The hydraulic pump is thus connected to the hydraulic circuit via the connection hole.

[0019] exist figure 1 The left-hand protruding drive shaft 8 runs completely through the housing section 2 and in the longitudinal direction of the web 4 . The penetration (not shown) of the web 4 serves as a penet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com