LED (light-emitting diode) light source module and packaging process thereof

An LED light source, LED chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of complex circuit connections, difficult to meet the requirements of light color uniformity and heat dissipation performance, achieve uniform light color, reduce open circuits, Good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

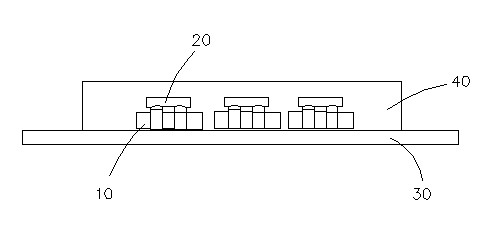

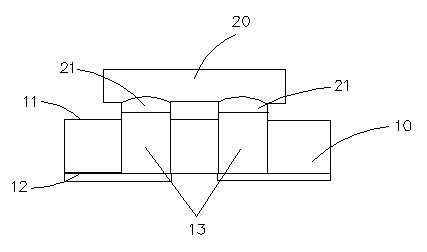

[0013] see figure 1 and figure 2 The LED light source module of the present invention includes several light source units and a substrate 30 , the light source unit includes a silicon chip 10 and a chip array 20 , the silicon chip 10 is set on the substrate 30 , and the chip array 20 is set on the silicon chip 10 .

[0014] see figure 2 1. The silicon chip 10 is made of insulating material such as ceramics. The silicon chip 10 includes an upper surface 11 and a welding surface 12 . Circuits are arranged on the upper surface 11 , and a plurality of via holes 13 are opened on the silicon chip 10 . The chip array 20 includes a plurality of LED chips 21 , the LED chips 21 are soldered on the via holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com