Bias power supply device for supersonic-frequency pulsed electron beam welding

A pulsed electron beam and bias power supply technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high welding beam current, affecting the quality of pulse beam current, bias pulse waveform distortion, etc. The effect of flexible control and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

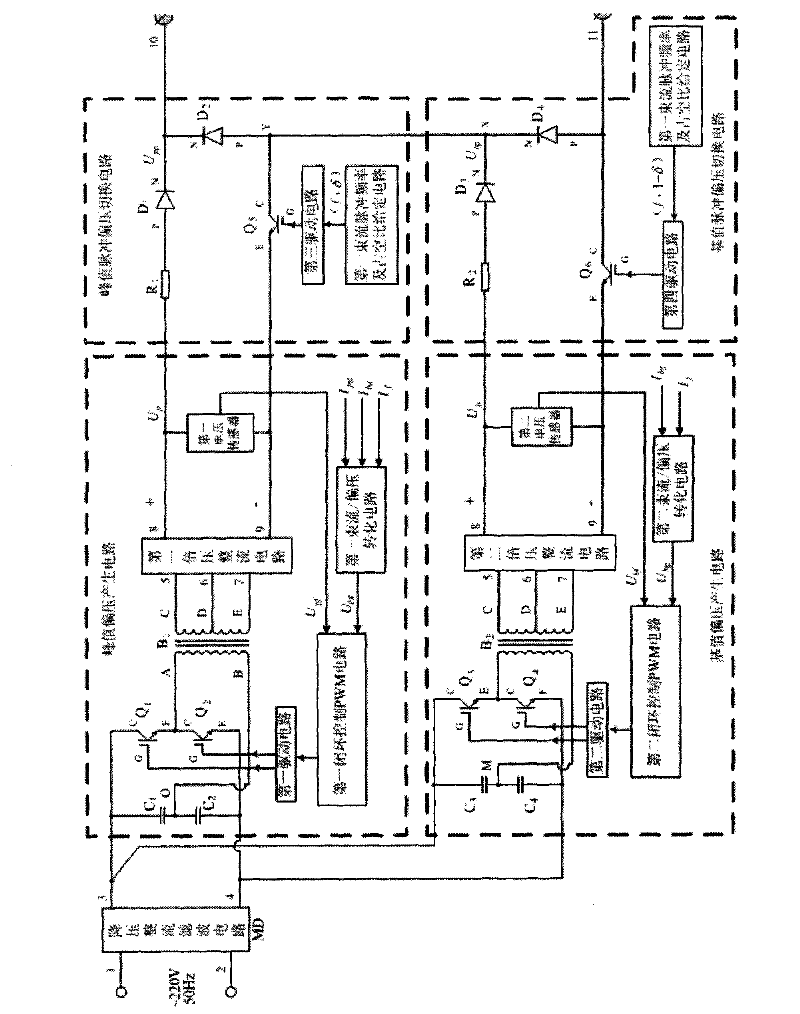

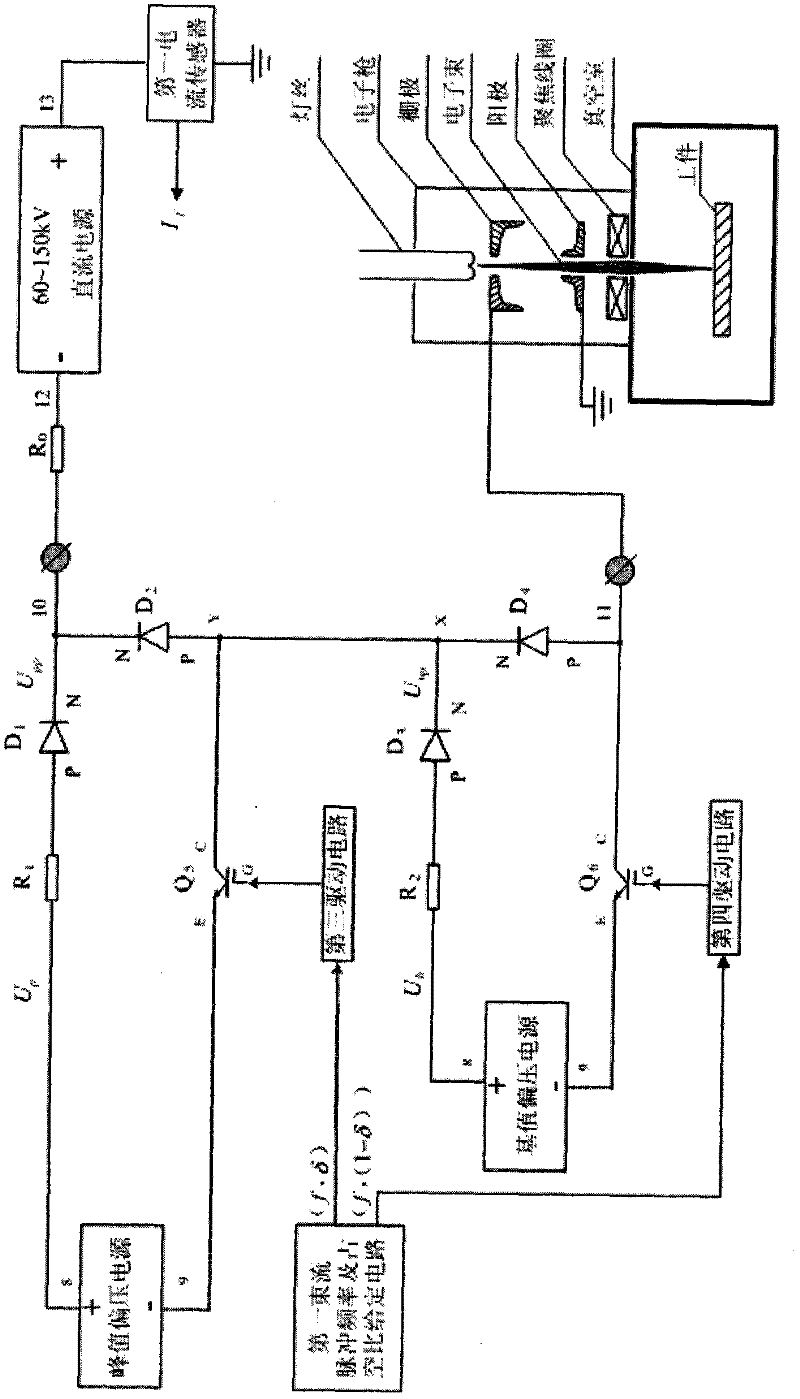

[0026] See attached figure 2 As shown, the bias power supply device of the ultra-audio frequency pulsed electron beam welding of the present invention is composed of a step-down rectification filter circuit, a peak bias voltage generation circuit, a base value bias voltage generation circuit, a peak value pulse bias switching circuit, a base value pulse bias voltage Composition of switching circuits.

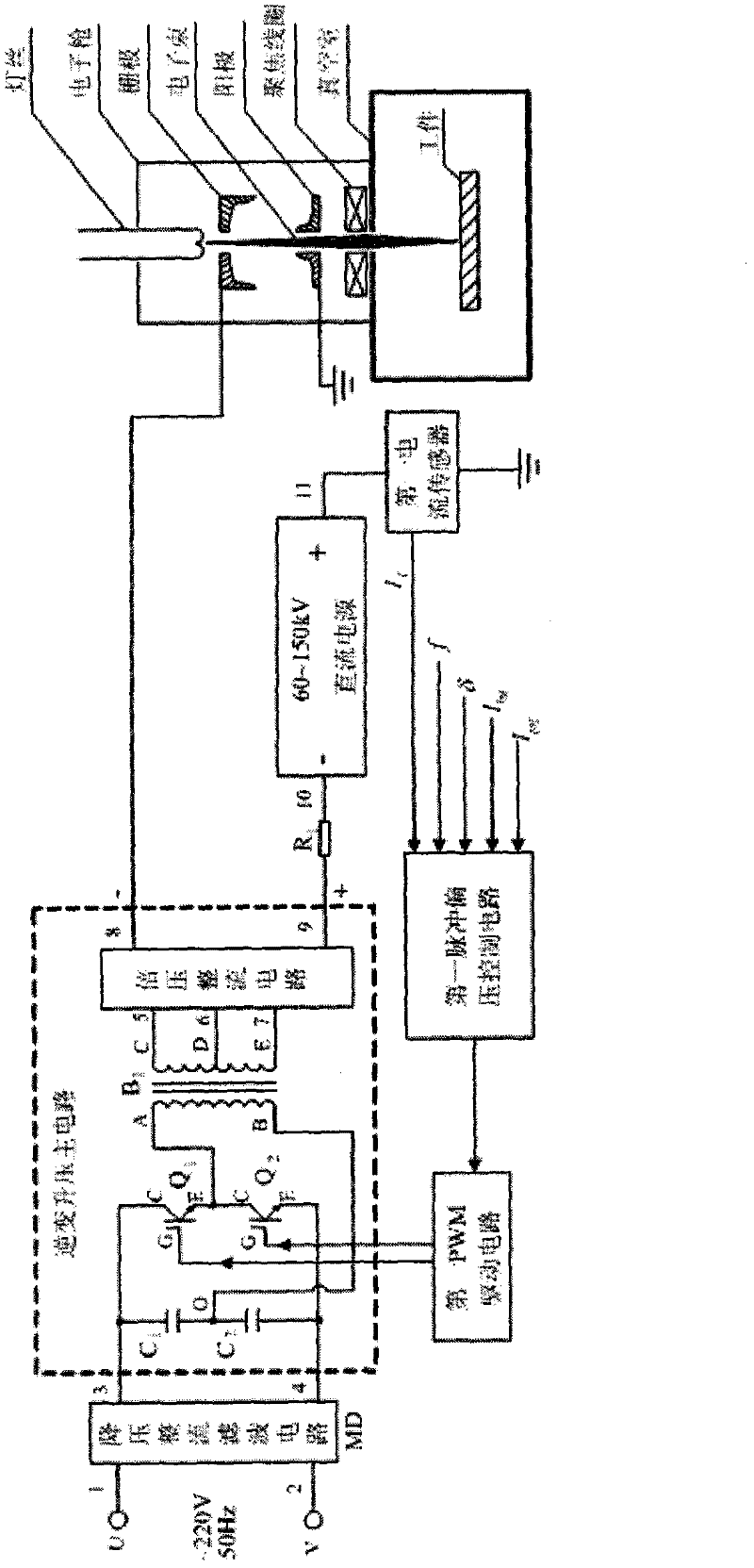

[0027] The step-down rectification filter circuit and the peak bias voltage generation circuit described in the present invention adopt such as figure 1 The conventional topological circuit structure shown. That is, the peak bias voltage generation circuit consists of a half-bridge inverter circuit, a first transformer B 1 , the first voltage doubler rectifier circuit, the first voltage sensor, the first beam current / bias c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com