Device for recovery and treatment of dirty oil generated in sewage treatment station system and treatment process thereof

A sewage treatment station and treatment device technology, applied in the direction of magnetic field/electric field water/sewage treatment, flocculation/sedimentation water/sewage treatment, only multi-stage series refining process treatment, etc., can solve the problem of oil-water separation effect, electric dehydrator Avoid problems such as collapsed electric field to achieve the effect of avoiding stable operation, convenient operation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

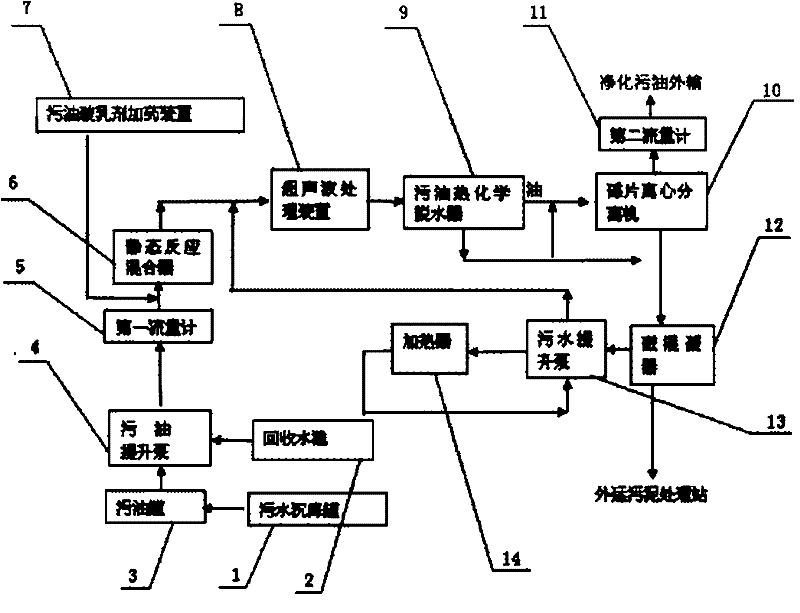

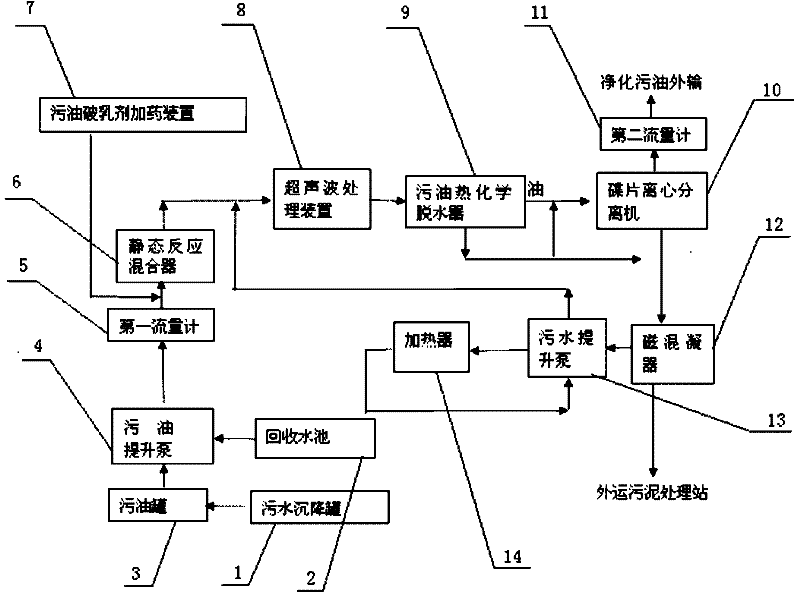

[0015] Specific implementation mode one: the following combination figure 1 Specifically illustrate this embodiment, the device of this embodiment comprises sewage settling tank 1, sewage oil tank 3, sewage oil lifting pump 4, first flow meter 5, static reaction mixer 6, sewage oil demulsifier dosing device 7, ultrasonic Treatment device 8, waste oil thermochemical dehydrator 9, three-phase disc centrifuge 10, second flow meter 11, magnetic coagulator 12, sewage lifting pump 13 and heater 14, sewage settling tank 1 and sewage oil tank 3 connected, the dirty oil tank 3 is connected with the first inlet port of the dirty oil lifting pump 4, the outlet port of the dirty oil lifting pump 4 is connected with the inlet port of the static reaction mixer 6 through the first flowmeter 5, and the dirty oil demulsifier is added The drug device 7 communicates with the inlet of the static reaction mixer 6, the outlet of the static reaction mixer 6 communicates with the inlet of the ultraso...

specific Embodiment approach 2

[0016] Specific embodiment two: the device of this embodiment also includes a recovery pool 2, and the recovery pool 2 is communicated with the second inlet port of the waste oil lift pump 4, and the waste oil lift pump 4 can separately lift the waste oil in the recovery pool 2 to a static state. Processed in reaction mixer 5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: the following combination figure 1 Specifically illustrate this embodiment, the technology of this embodiment comprises the following steps: Step 1, the dirty oil that produces in the sewage settling tank 1 enters the dirty oil tank 3, and the dirty oil in the dirty oil tank 3 is lifted by the dirty oil lifting pump 4 through the first step A flow meter 5 enters the static reaction mixer 6;

[0018] Step 2, use the dirty oil demulsifier dosing device 7 to add the demulsifier to the static reaction mixer 6 (whether the components can be given), the dirty oil and the demulsifier are mixed in the static reaction mixer 6 and then enter the ultrasonic treatment device 8 Carry out the demulsification reaction of dirty oil, wherein the operating voltage of the ultrasonic treatment device is 380V, the operating frequency is 30-40KHz, the working temperature is 50-60°C, and the residence time of the dirty oil is 20min;

[0019] Step 3: The wa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap