Turbine power generating system by utilizing wind from train travelling

A technology of power generation system and wind power generator, applied in the direction of wind power generator at right angles to the wind direction, wind power motor, wind power motor combination, etc., can solve the problems of voltage value fluctuation, large output voltage fluctuation, and shortened service life, and achieve structural Simple and reasonable, improved reliability, large torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

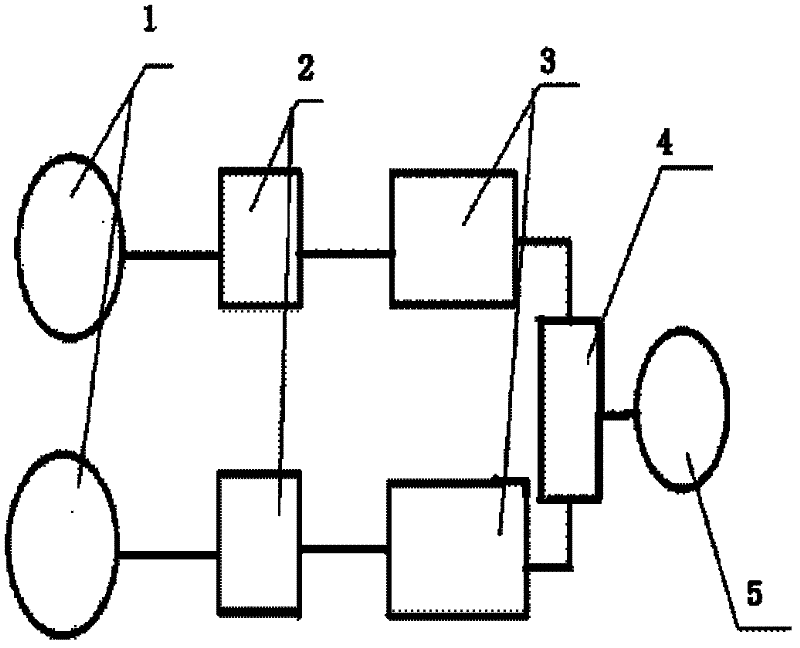

[0027] figure 1 The schematic diagram of the overall scheme of the Nakamoto system takes a group of power generation units on both sides of the road as an example. The power generation units include wind turbine 1, controller 2, and battery pack 3; The controller 2 is electrically connected; the controller 2 is electrically connected to the battery pack 3; each battery pack 3 is electrically connected to the power distribution device 4; the power distribution device 4 is electrically connected to the load 5.

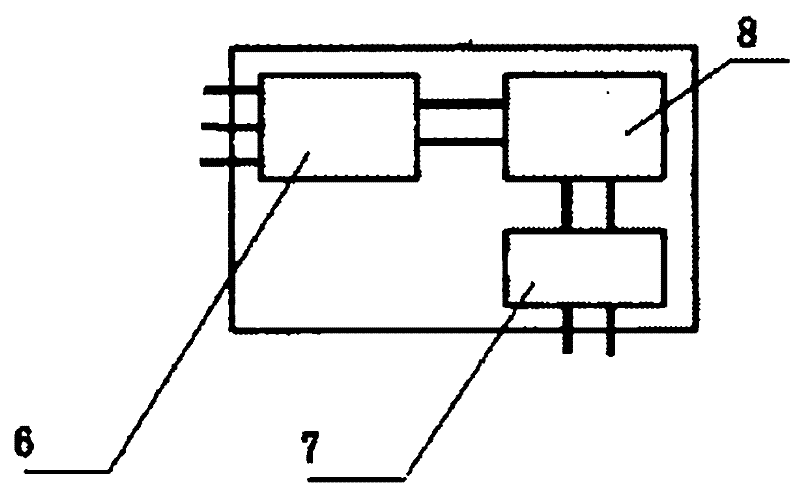

[0028] figure 2 The middle is a schematic diagram of the electrical and control parts. In the figure, the rectifier 6, the chopper 7 and the charger 8 are electrically connected in sequence.

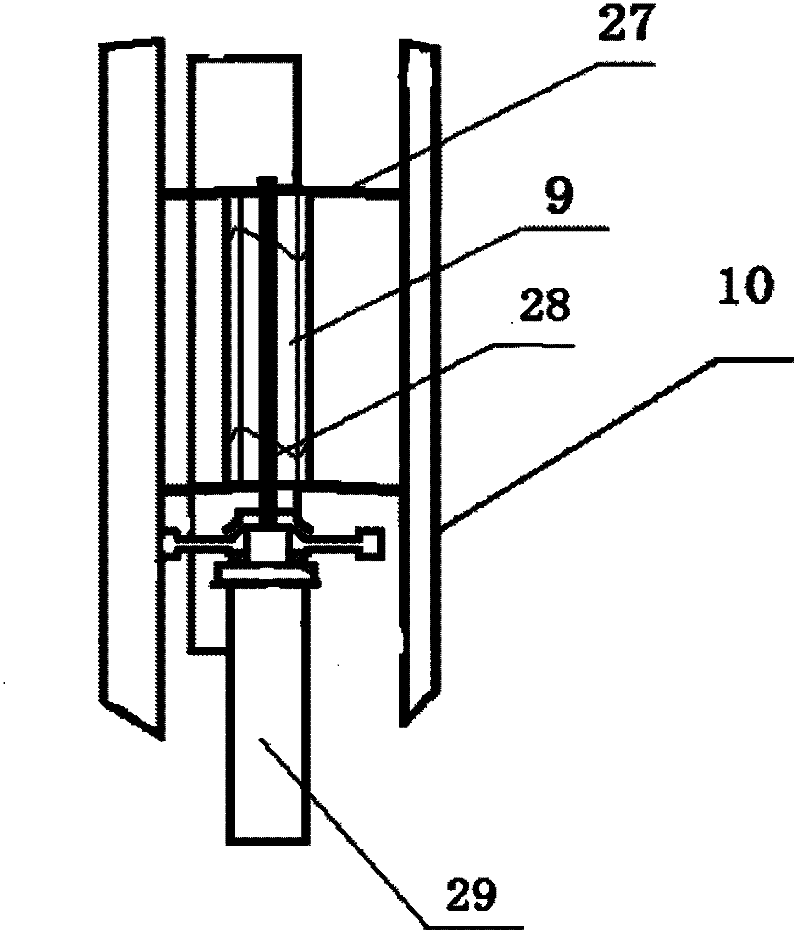

[0029] image 3 It is a structural schematic diagram of a vertical-axis wind-driven generator. The shaft 28 of the vertical-axis wind-driven generator 1 is in the vertical direction, and the shaft 28 is provided with an S-shaped wind wheel 9, an H-shaped wind wheel 10, and a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com