Novel speed reducer and speed reduction motor

A planetary reducer and geared motor technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of difficult consistency of precision, poor stiffness, high noise, etc., and achieve reasonable structural design, large bearing capacity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

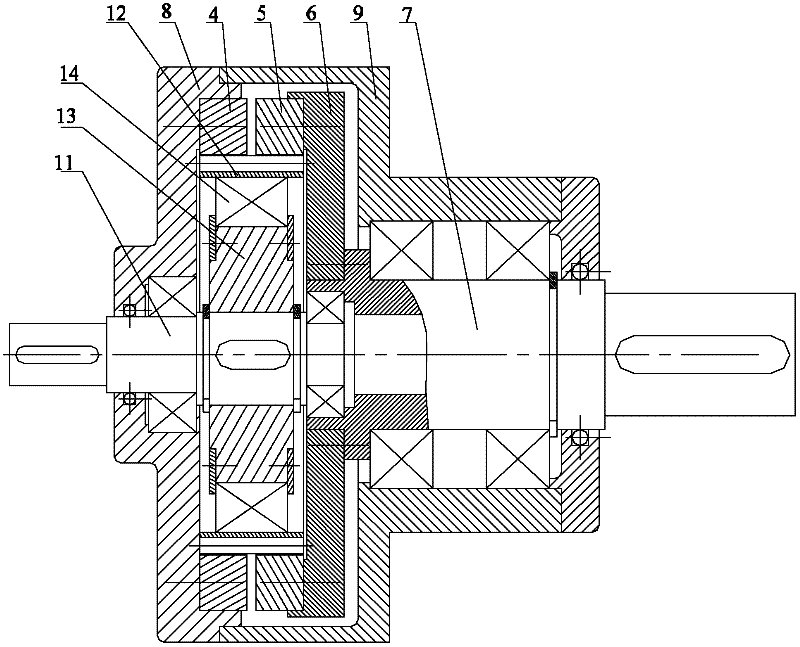

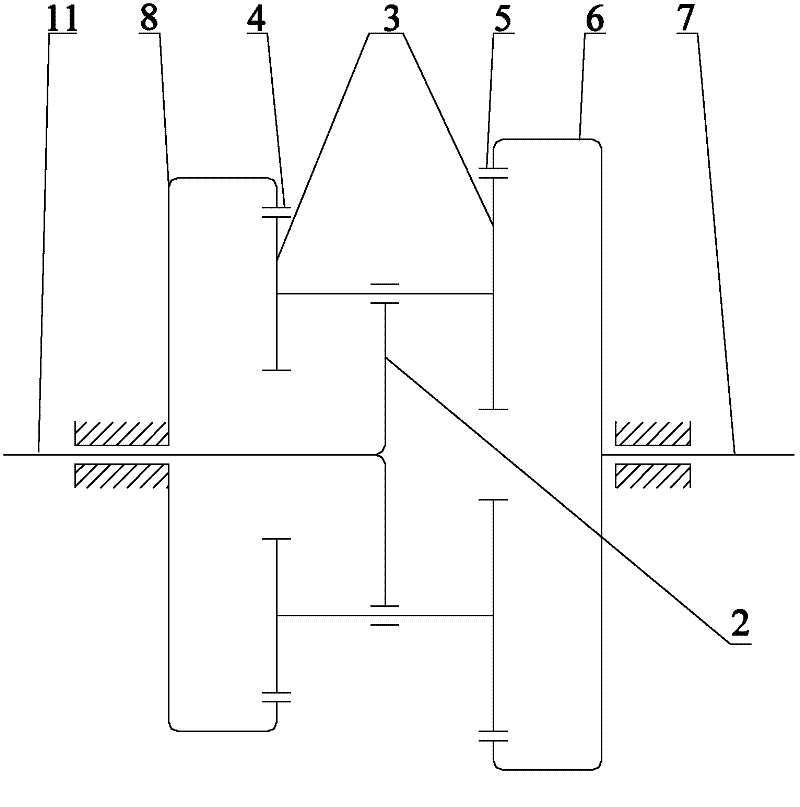

[0037] See image 3 , image 3 It is a cross-sectional view of a new type of planetary reducer provided by the present invention. among them, image 3 The new type planetary reducer shown can also be referred to as an imitation harmonic gear planetary reducer.

[0038] Such as image 3 Said, this new type of planetary reducer may include: a planetary carrier 2 fixed on the input shaft 11 and with a planetary gear 3; a fixed ring gear 4 fixed on the end cover 8, and a fixed ring 6 fixed on the coupling disc 6. An output shaft 7 is fixed on the coupling disc 6; the housing 9 is positioned on the output shaft 7 through a bearing, and the end cover 8 is positioned on the input shaft 11 through a bearing. The housing 9 is fastened to the end cover 8; the fixed internal gear ring 4 is coaxial with the input shaft 11; the movable internal gear ring 5 is coaxial with the output shaft 7; the fixed internal gear ring 4 and the moving internal gear ring 5 have the same size, but different ...

Embodiment 2

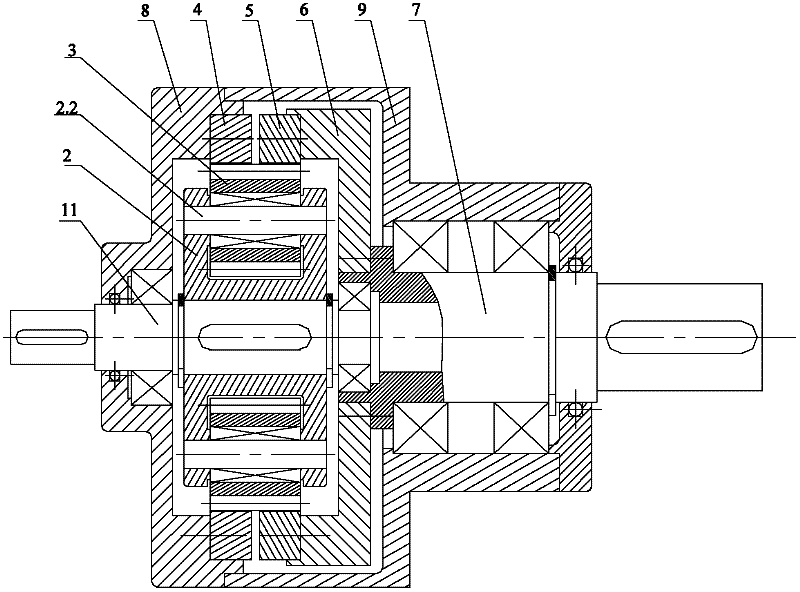

[0052] See Figure 4 , Figure 4 A cross-sectional view of a geared motor provided by the present invention. among them, Figure 4 The geared motor shown can also be referred to as a harmonic-like gear planetary geared motor.

[0053] in Figure 4 In the geared motor shown, the motor stator 1 is fixed on the end cover 8, and the end cover 8 is fastened to the housing 9; the housing 9 is fastened with a fixed internal gear ring 4, and the movable internal gear ring 5 is fixed on On the coupling disk 6, an output shaft 7 is fixed on the coupling disk 6; a planetary gear carrier 2 is fixed on the outer rotor 1.1 of the motor, and the planetary gear carrier 2 is provided with a planetary gear 3; the motor stator 1 and the The planetary carrier 2 is positioned on the output shaft 7 through bearings; the fixed internal gear 4 and the dynamic internal gear 5 have the same size and different numbers of teeth; the fixed internal gear 4 and the dynamic internal gear The ring gears 5 are c...

Embodiment 3

[0059] See Figure 7 , Figure 7 It is a cross-sectional view of another geared motor provided by the present invention. among them, Figure 7 The geared motor shown can also be referred to as a harmonic-like planetary geared hub motor for electric vehicles.

[0060] in Figure 7 The geared motor shown includes a housing 9, an end cover 8 locked at both ends of the housing 9, a motor stator 1, a motor outer rotor 1.1, and a central shaft 7.1; the motor stator 1 is fixed on the central shaft 7.1 On the outer rotor 1.1 of the motor, a planetary carrier 2 is fixed, and the planetary carrier 2 with planetary gears 3 is positioned on the central shaft 7.1 through bearings; a fixed ring gear 4 is fastened on the housing 9 , The movable inner gear ring 5 is fixed on the coupling disc 6, the inner ring of the coupling disc 6 is provided with a secondary coupling disc 6.1 fixed on the central shaft 7.1, and a unidirectional pivot is provided between the coupling disc 6 and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com