Domestic garbage pyrolysis gasification treatment complete equipment

A technology of pyrolysis gasification and complete sets of equipment, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve problems such as the entry of harmful substances, secondary pollution, and complex composting technology process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

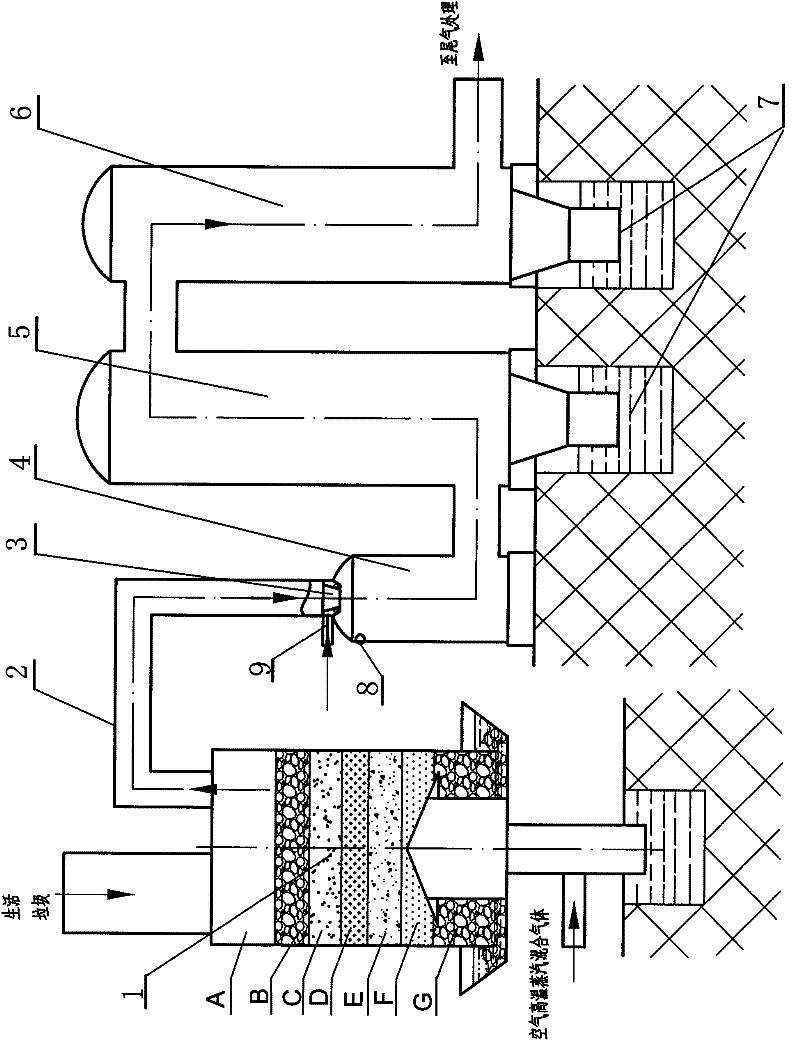

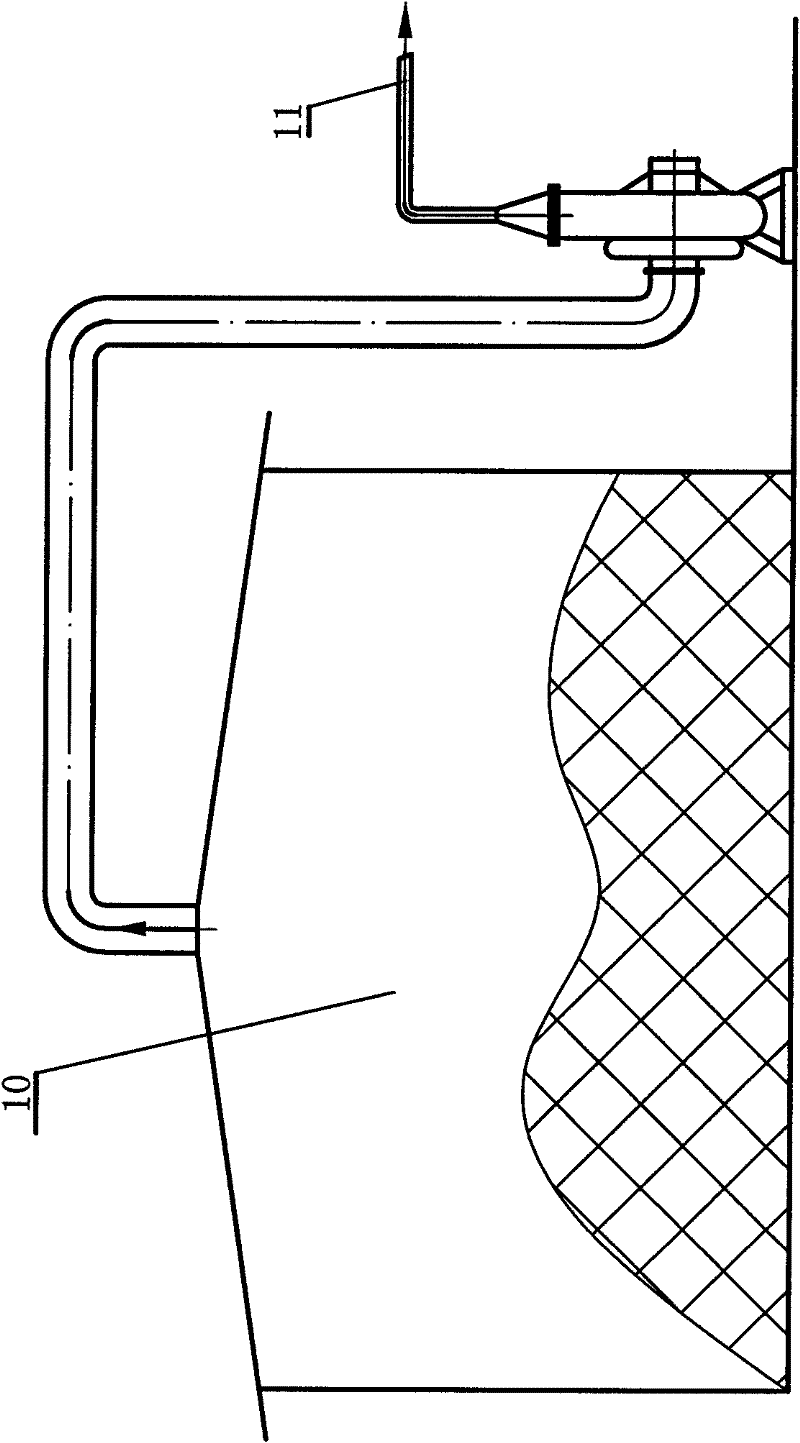

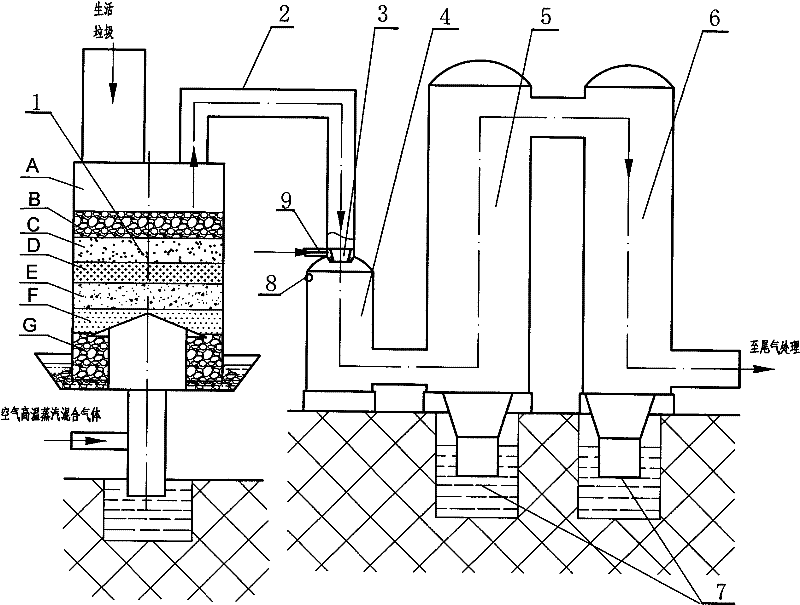

[0011] Such as figure 1 As shown, this implementation includes a garbage pyrolysis gasification gas generator 1 , a preheating furnace 4 , a combustion furnace 5 and a combustion furnace 6 .

[0012] The structural design and connection form of the combustion furnace and the ember furnace are aimed at suppressing the generation of dioxin-like precursors, separating non-combustible solid particles, and fully burning tar. The design complies with the 3T principles of international furnaces (Temperature, that is, maintaining high temperature, above 800°C; Time, that is, maintaining the full combustion time of gas; Turbulence, that is, gas turbulence effect) and solid particle specific gravity separation method.

[0013] The gas outlet of the garbage pyrolysis gasification gas generator 1 is connected to the gas inlet at the top of the preheating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com