Induction-type tank welding seam drying and heating device

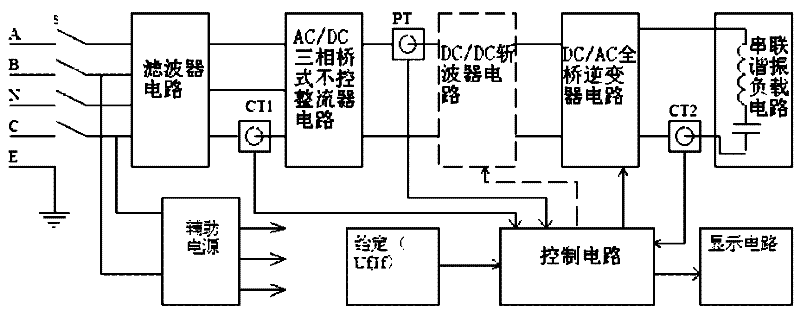

A technology of drying heating and induction heating, applied in the direction of heating device, induction heating, induction heating control, etc., can solve the problems of high energy consumption, poor work control precision, low efficiency of heating device, etc., to solve electromagnetic radiation and prevent electromagnetic radiation The effect of leakage and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

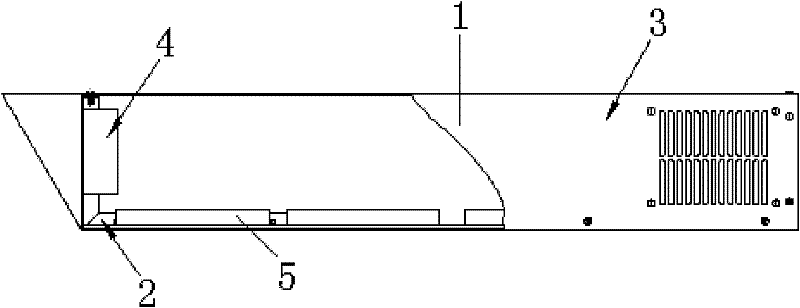

[0023] Such as figure 1 shown. The heating body 1 includes a bottom frame 2 and an upper cover 3 covering the bottom frame 2. An air duct is formed between the upper cover 3 and the bottom frame 2; a fan 4 is installed at the air inlet of the air duct, and the air outlet of the fan 4 In the opposite air duct. Glass-ceramic is fixedly installed on the frame wall of the bottom frame 2, and a number of coil disks 5 connected in series or in parallel are arranged and distributed on the glass-ceramic, and a magnet block is attached to the upper surface of each coil disk 5. A temperature sensor is installed on the loam cake 3 .

[0024] During the working process, the tank body is placed on the transmission belt, and is transported from one end of the transmission belt to the other end of the transmission belt. During the process of being transported, it is continuously heated by the heating body, thereby achieving the effect of drying the weld seam on the tank body.

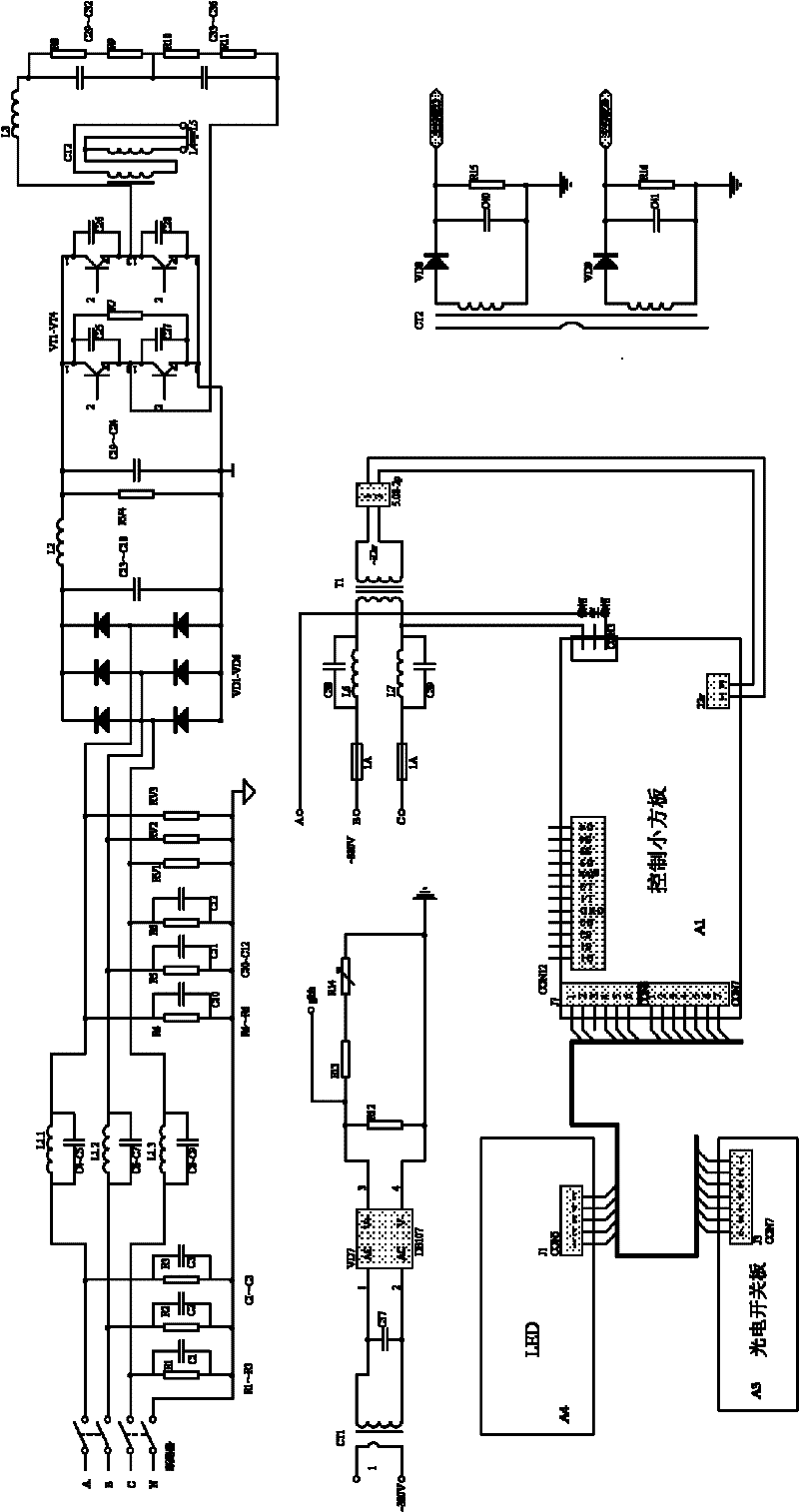

[0025] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com