High-altitude crimping apparatus of power transmission line

A technology of crimping device and transmission line, which is applied in the direction of connection and connection by deformation, equipment for connection/termination of cables, etc. It can solve the problems of loose wires to the ground, inability to bend easily, and large volume of crimping machines, etc., to achieve Reduce the danger of high-altitude operations, ensure stability and reliability, and facilitate installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

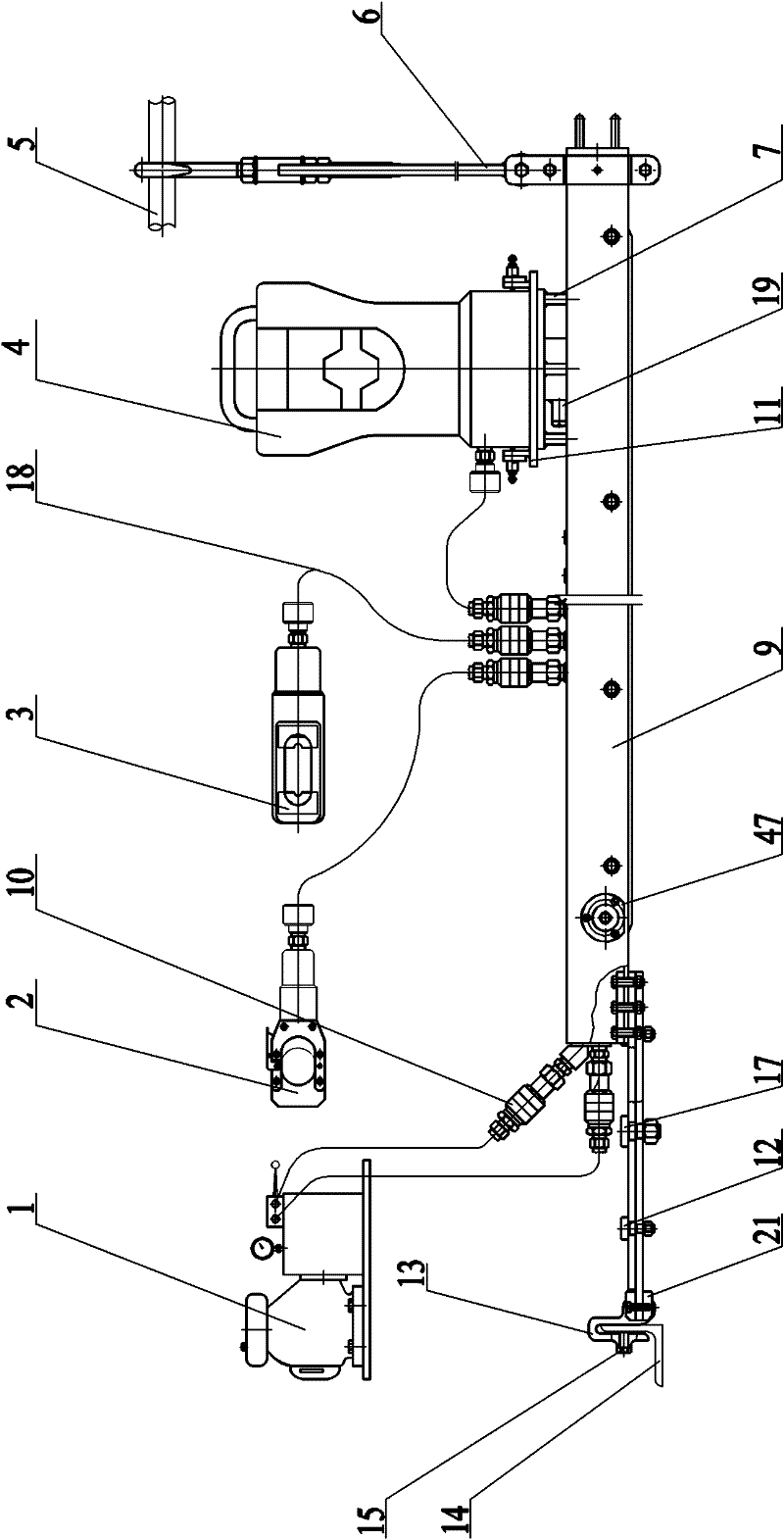

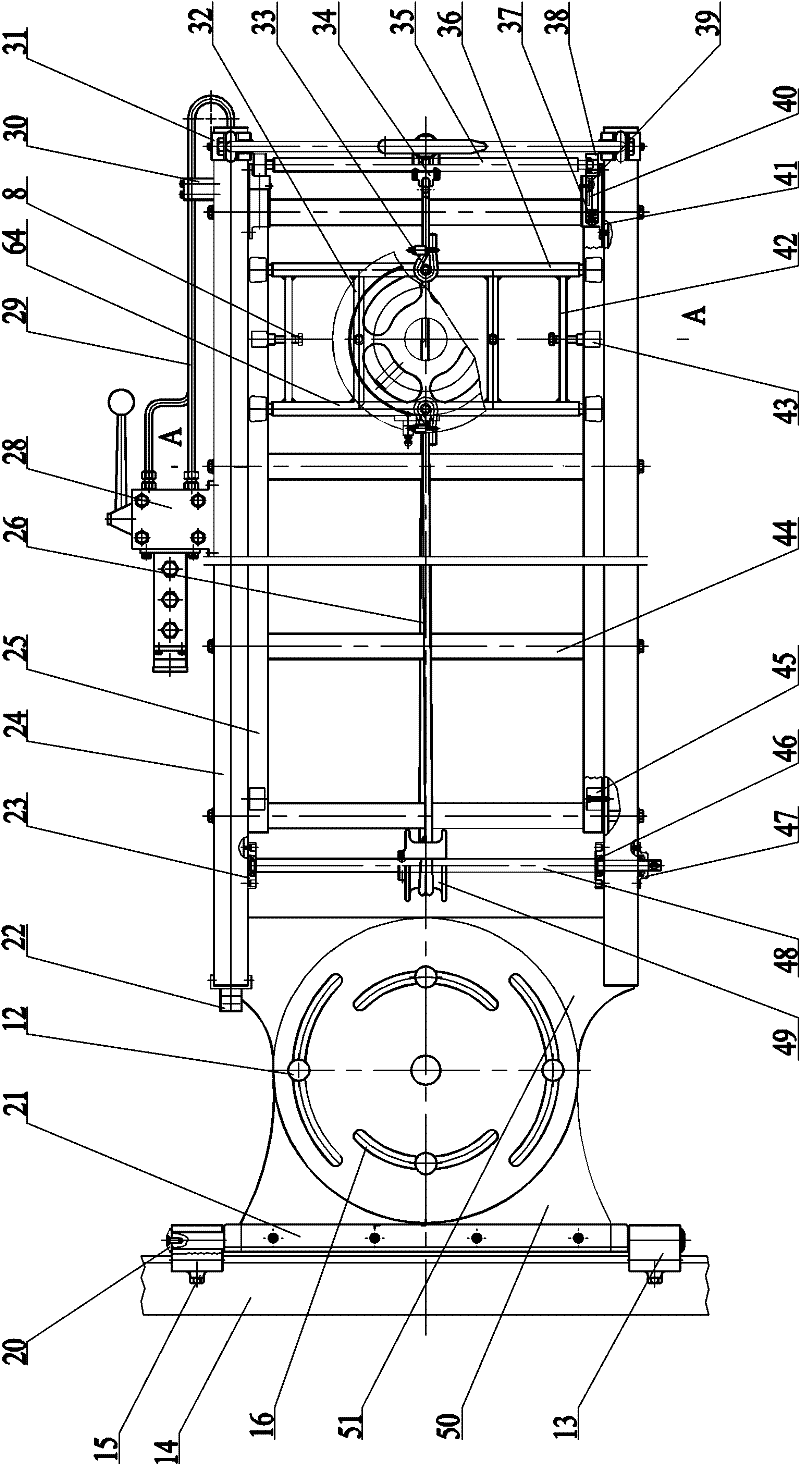

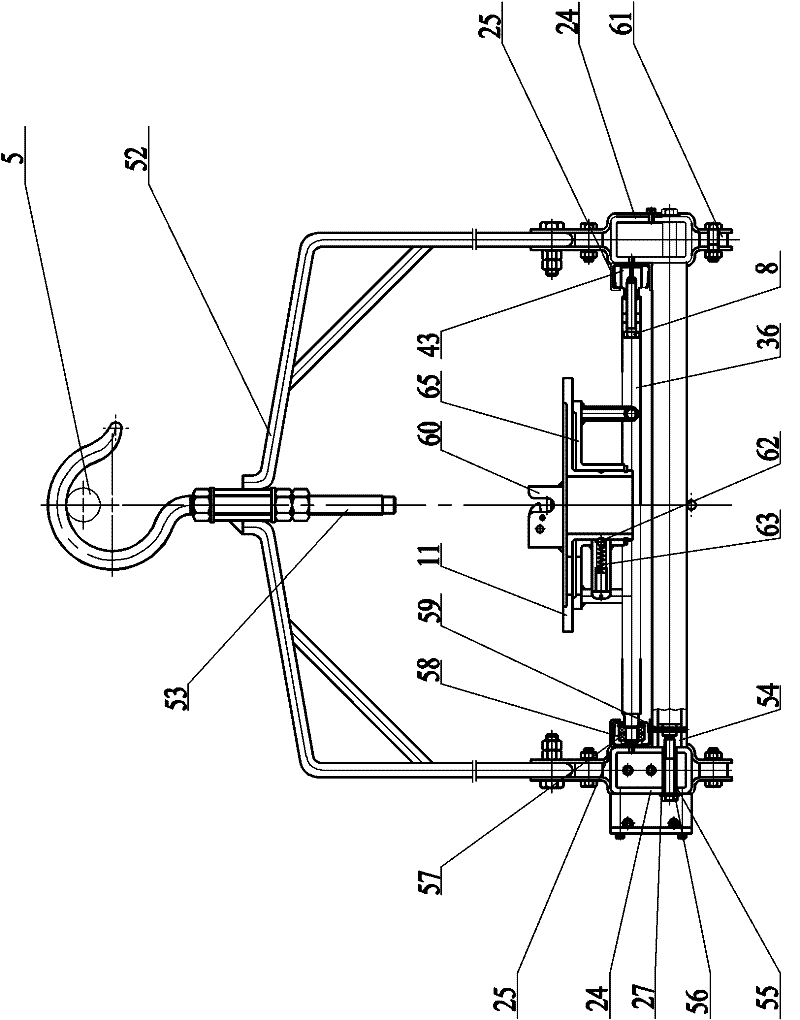

[0019] like Figure 1~Figure 3 As shown: the present invention includes oil pump 1, hydraulic scissors 2, hydraulic wire stripper 3, crimping machine 4, fixed cable 5, hook 6, crimping machine chassis support 7, locking adjustment bolt 8, horizontal ladder 9, oil pipe Quick connector 10, crimping machine turntable 11, rotary bolt 12, cross arm buckle 13, iron tower angle iron 14, buckle fastening bolt 15, arc groove 16, center bolt 17, oil pipe connecting pipe 18, steel ball sleeve 19. Buckle screw 20, hinge shaft 21, oil pipe joint 22, rocker shaft inner seat 23, main beam 24, crimping machine guide rail 25, traction rope 26, washer 27, distribution valve 28, oil pipe 29, oil pipe limit block 30. Lifting clip 31, crosspiece between shafts 32, wire clamp 33, first sheave 34, sheave shaft 35, roller shaft 36, sheave shaft compression spring 37, sheave shaft pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com