ACF attachment device and display device manufacturing method

A technology for pasting devices and manufacturing methods, which is applied in the fields of identification devices, printed circuit manufacturing, semiconductor/solid-state device manufacturing, etc. It can solve the problems of easy sliding of ACF tapes, lower equipment operation rate, and error adjustment of ACF tapes, and achieve beautiful end face shape , reduced auxiliary material costs, positional accuracy and high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

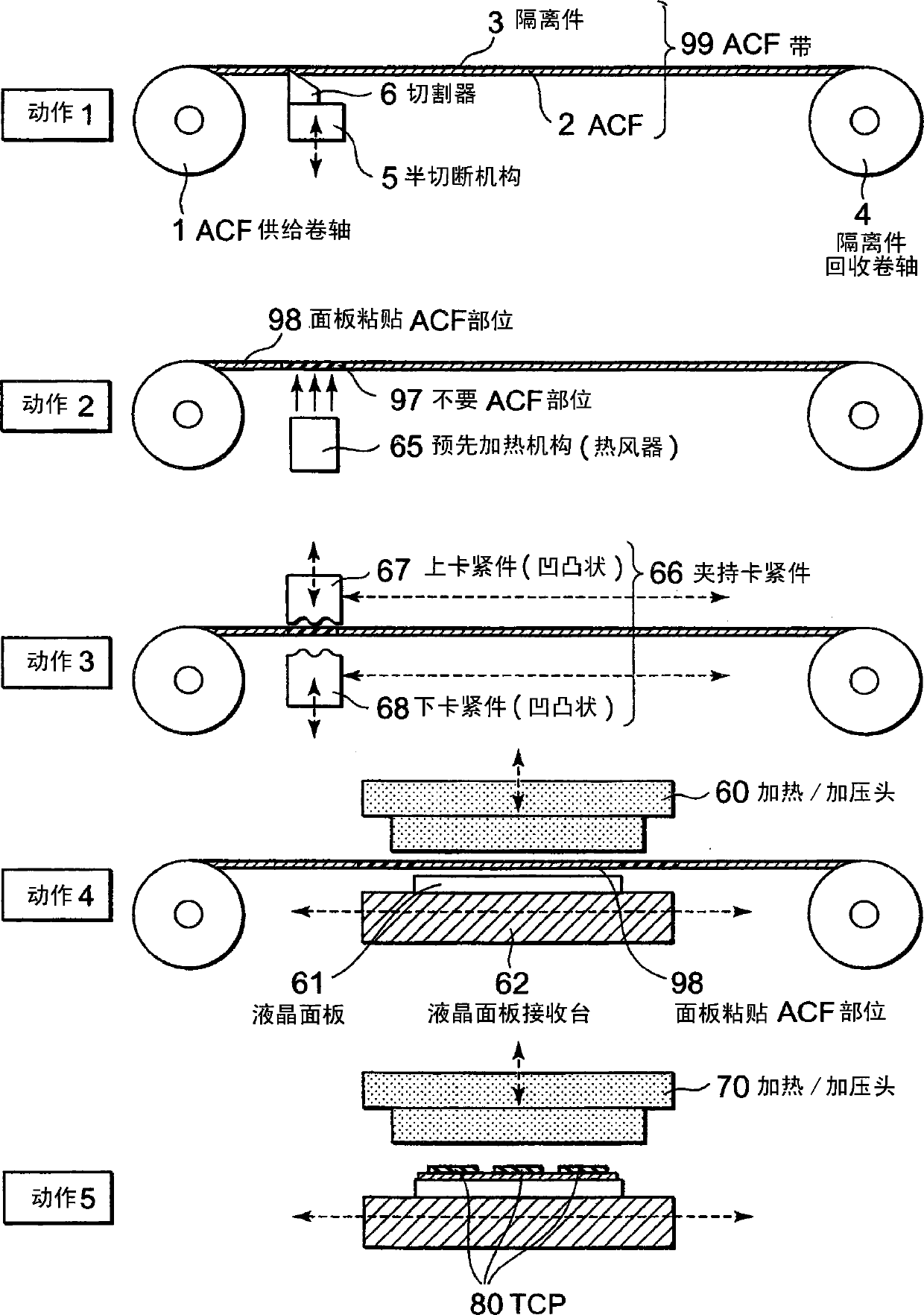

[0043] In order to further describe the above-mentioned embodiments of the present invention in detail, refer to figure 1 and figure 2 A first embodiment of the present invention will be described.

[0044] like figure 1 As shown, the ACF pasting device of this embodiment at least includes: ACF supply reel 1, spacer recovery reel 4, half-cut mechanism 5, preheating mechanism 65, clamping and clamping member 66, heating / pressurizing head 60, liquid crystal panel receiving station 62 . In addition, the ACF tape 99 is generally composed of a double-layer structure of the ACF 2 and the cover film called the spacer 3 .

[0045] Next, the operation of the ACF pasting device of the embodiment will be described.

[0046] In "Operation 1", first, the cutter 6 of the half-cutting mechanism 5 half-cuts the ACF tape 99 that imparts thermosetting properties and integrates the ACF 2 and the separator 3 .

[0047] The half cutting is performed by bringing the cutter 6 into contact wi...

Embodiment 2

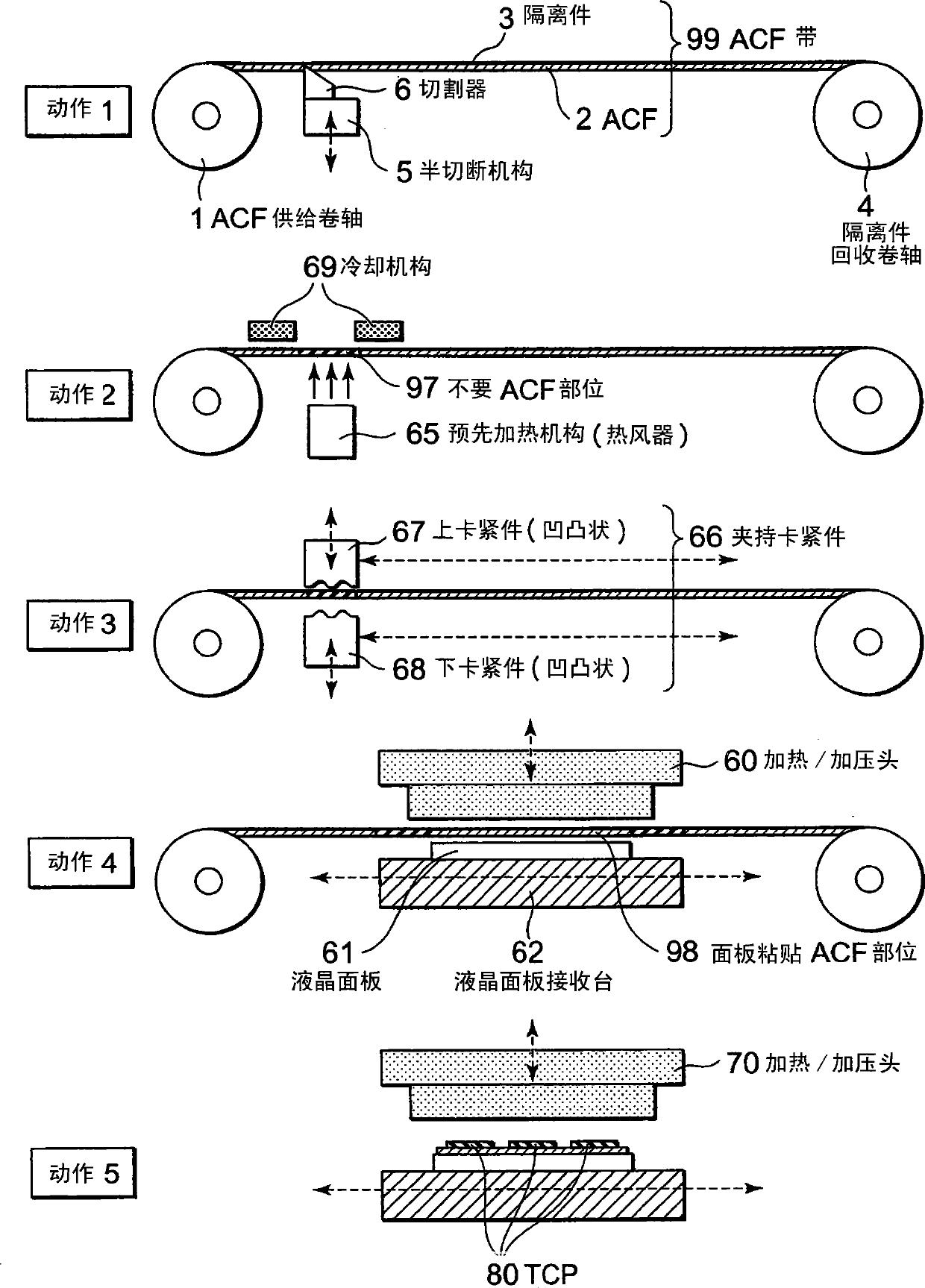

[0074] Second, refer to image 3 A second embodiment of the present invention will be described.

[0075] The basic structure of the ACF pasting device of this embodiment is the same as that of Embodiment 1, but as image 3 As shown in "Action 2" of , the difference from the first embodiment is that a cooling mechanism 69 is provided in order to suppress the hardening of the panel bonding ACF portion 98 adjacent to the unnecessary ACF portion 97 . Hereinafter, this difference will be described.

[0076] In this embodiment, before the heater of the preheating mechanism 65 is turned on, the cooling mechanism 69 is lowered so that the spacer 3 at the ACF portion 98 of the panel is in contact with the cooling mechanism 69 . Accordingly, it is possible to suppress the heating of the panel bonding ACF portion 98 .

[0077] After the unnecessary ACF portion 97 is cured, the preheating mechanism 65 is turned off to stop blowing of warm air, and the cooling mechanism 69 is further r...

Embodiment 3

[0081] Second, refer to Figure 4 A third embodiment of the present invention will be described.

[0082] In this example, if Figure 4 As shown in "Action 2", the cooling mechanism 69 is provided in order to prevent the hardening of the panel-attached ACF portion 98 adjacent to the unnecessary ACF portion 97. The contact heater is different in that the unnecessary ACF portion 97 is removed by the belt recovery mechanism 57 before the ACF belt 99 is clamped by the clamping member 66 .

[0083] The difference will be described below.

[0084] like Figure 4 As shown in “Action 2 ”, after aligning the unnecessary ACF portion 97 of the ACF belt 99 with the preheating mechanism 64 , the preheating mechanism 64 is raised toward the unnecessary ACF portion 97 . At this time, the tape supply mechanism 56 and the tape recovery mechanism 57 are interlocked, and the tape 55 positioned between the preheating mechanism 64 and the ACF tape 99 is raised while being supported by the preh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com