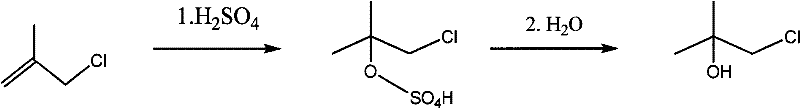

Method for preparing 1-chloro-2-methyl-2-propanol

A technology of methyl and propanol, which is applied in the preparation of hydroxyl addition, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of increasing production costs, high prices, and uneconomical promotion of enterprise products. and other problems to achieve the effect of reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] First the cation exchange resin is filled in the filling tube, and there are two feeding ports at one end of the filling tube, one is the feeding port of water inlet, and the other is the feeding port of entering 3-chloro 2-methylpropene; then the Water is injected (by a pump) into the filling tube filled with cation exchange resin from the water feeding port of the filling tube. Here, the filling tube is a filling tube with a length of 1 meter and a diameter of 30 cm; the filling tube is placed horizontally;

[0019] Maintain the flow rate of water added to the filling pipe at 10L / h until the filling pipe is completely filled with water (that is, the water is evenly filled), and then feed water and 3-chloro-2-methylpropene from the two feed ports respectively. Use a pump to inject into the filling tube filled with cation exchange resin; cool the outside of the filling tube with a 0°C ice-water mixture to ensure that the temperature inside the filling tube is between 0 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com