Method and device for generating electricity by using afterheat of high-temperature steel smelting slag

A technology for iron and steel smelting and waste heat power generation, which is applied in the steam generation method using heat carrier, waste heat treatment, steam engine installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

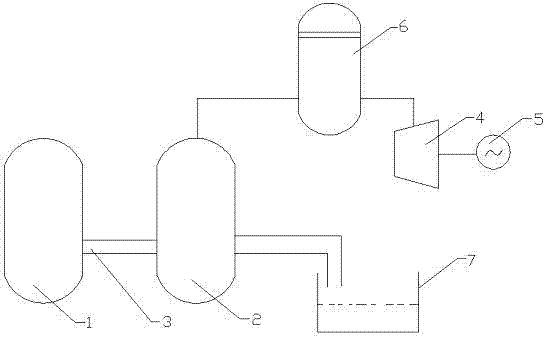

[0022] The invention provides a method for power generation with high-temperature waste heat from iron and steel smelting waste residues. The specific method is to use the heat energy stored in the remaining waste slag from iron and steel smelting to heat water to generate steam, and then use the generated steam to generate electricity. In order to obtain a stable power source during the power generation process , the pressure of the steam needs to be adjusted before power generation, so that it becomes a steam with stable pressure and continuous discharge output.

[0023] The method of the invention can effectively recycle the heat energy stored in the high-temperature waste slag generated in the iron and steel smelting process for power generation, avoiding energy waste, and the transformed electric energy can be transported to various industrial or civil places for use, realizing energy reuse At the same time, it also has certain economic benefits.

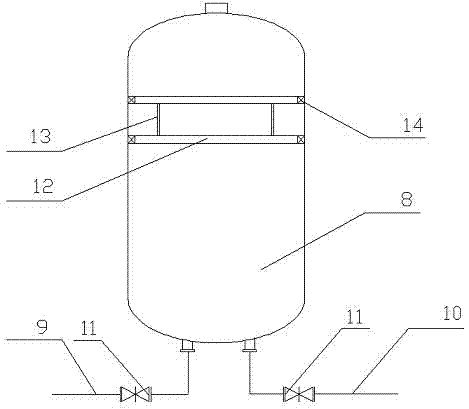

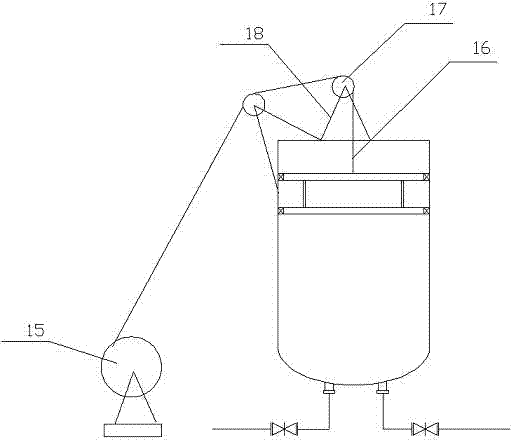

[0024] see figure 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com