Structure of large-scale flywheel blank and manufacturing method

A manufacturing method and flywheel technology, which can be applied to flywheels, manufacturing tools, auxiliary devices, etc., can solve the problems of welding quality defects, easy cracking of welding seams, etc., and achieve the effect of low manufacturing cost

Inactive Publication Date: 2011-11-09

李建华

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The object of the present invention is to provide a structure and manufacturing method of a large flywheel blank, which overcomes the defects in the structure and manufacturing method of the existing large flywheel blank, which are prone to defects in welding quality and easy cracking of weld seams

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

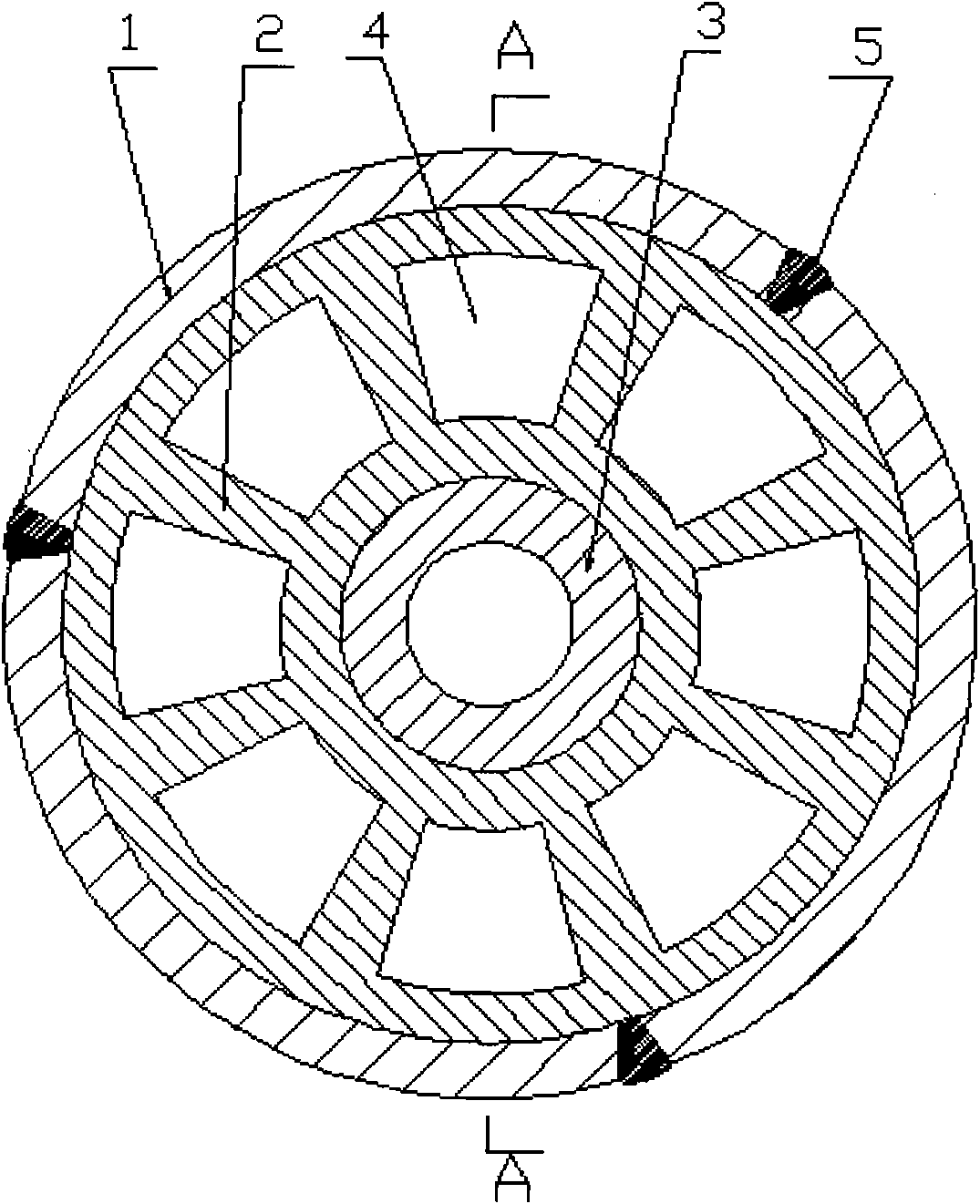

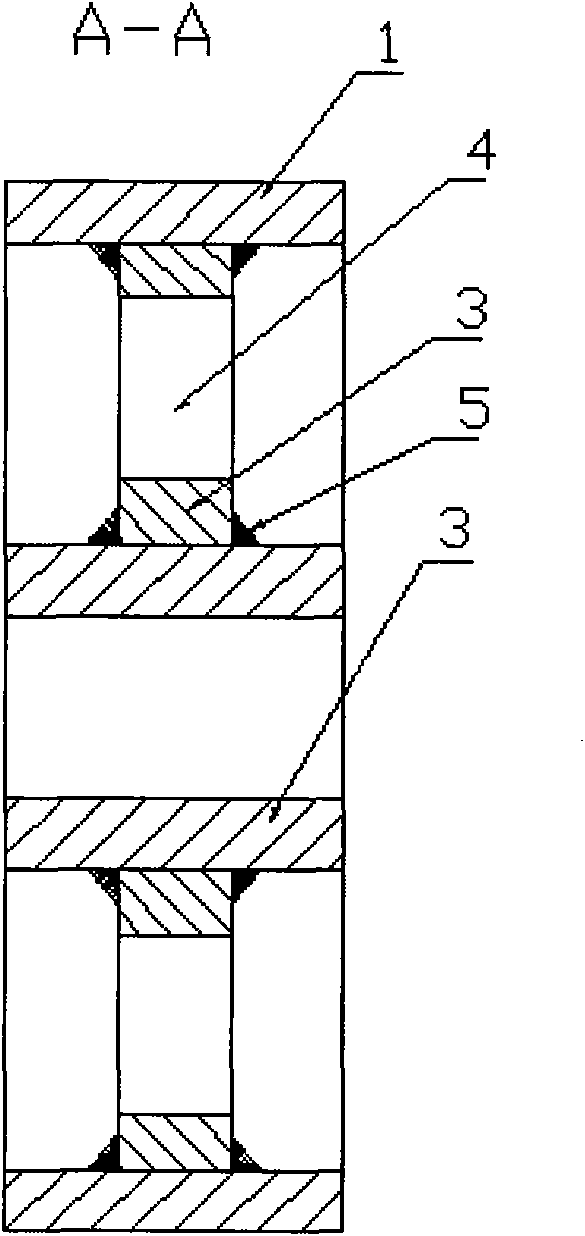

[0010] The arc-shaped wheel rim (1), wheel spoke (2) and wheel hub (3) are respectively manufactured by using medium-carbon steel or low-carbon steel plate materials of the same brand. The welding method is spliced, and fan-shaped holes (4) are uniformly opened in the plane of the spokes, and then the above-mentioned components are welded together through welding seams (5).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a structure of a large-scale flywheel blank and a manufacturing method. In the structure, a rim, a spoke and a hub are made of a medium carbon steel or low-carbon steel plate material which is of the same brand, wherein the rim is formed by splicing circular arcs which are rolled by multiple sections of steel plates by a welding method; fan-shaped holes are formed in a plane of the spoke uniformly; and the components are welded by a welding method to overcome the defect of welding quality in a structure of the conventional large-scale flywheel blank and a manufacturing method and the defect that weld joints are easy to crack. Simultaneously, compared with the conventional structure and the manufacturing method, the structure has the advantage of low manufacturing cost.

Description

technical field [0001] The invention relates to a structure and a manufacturing method of a flywheel blank, in particular to a structure and a manufacturing method of a large flywheel blank, and belongs to the technical field of mechanical manufacturing technology. Background technique [0002] Traditionally, flywheel blanks are generally manufactured by casting, especially for large flywheel blanks, most of them are manufactured by casting. With the development of market economy, customers often need to order when purchasing mechanical products. For some special, large and non-standard products, when the enterprise organizes the production, it should also organize the production in small batches and multiple varieties according to the requirements of the market to meet the needs of the market. These products sometimes include large flywheels. If conventional The method of casting not only has the defect of long production cycle, but also has the defect of high cost in the c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16F15/30B23K37/00B23K101/04

Inventor 李建华

Owner 李建华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com