LED (light emitting diode) heat radiation packaging structure with air outlet at side face

A side air outlet and encapsulation structure technology, applied in cooling/heating devices of lighting devices, lighting devices, lighting and heating equipment, etc., can solve problems such as complex operation, danger, and heat transport crisis, and achieve good heat dissipation performance, Compact structure and powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

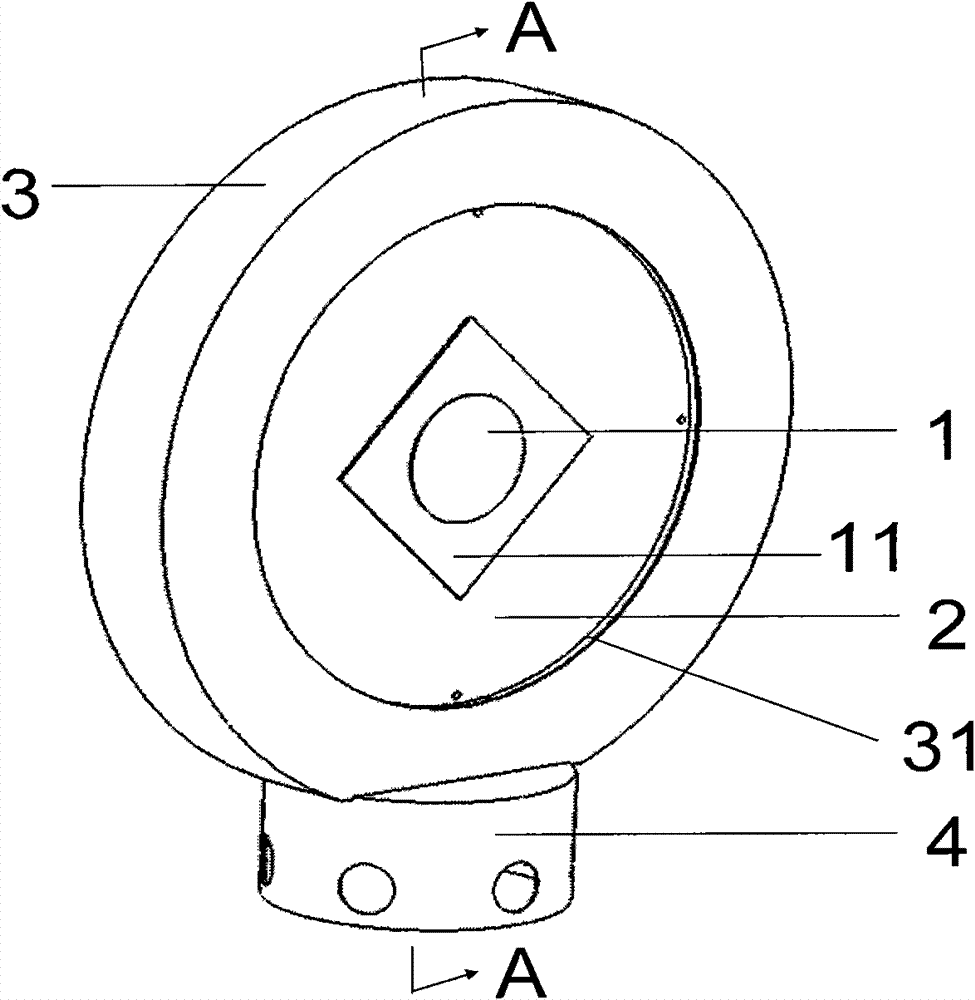

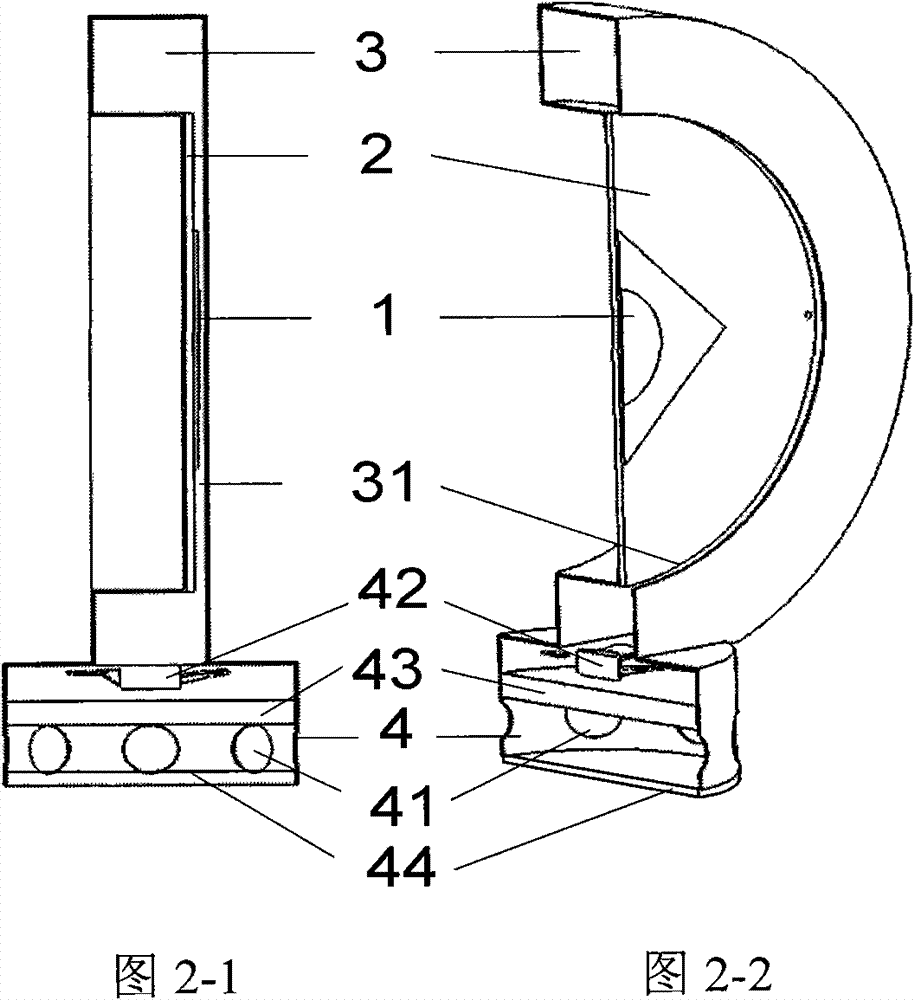

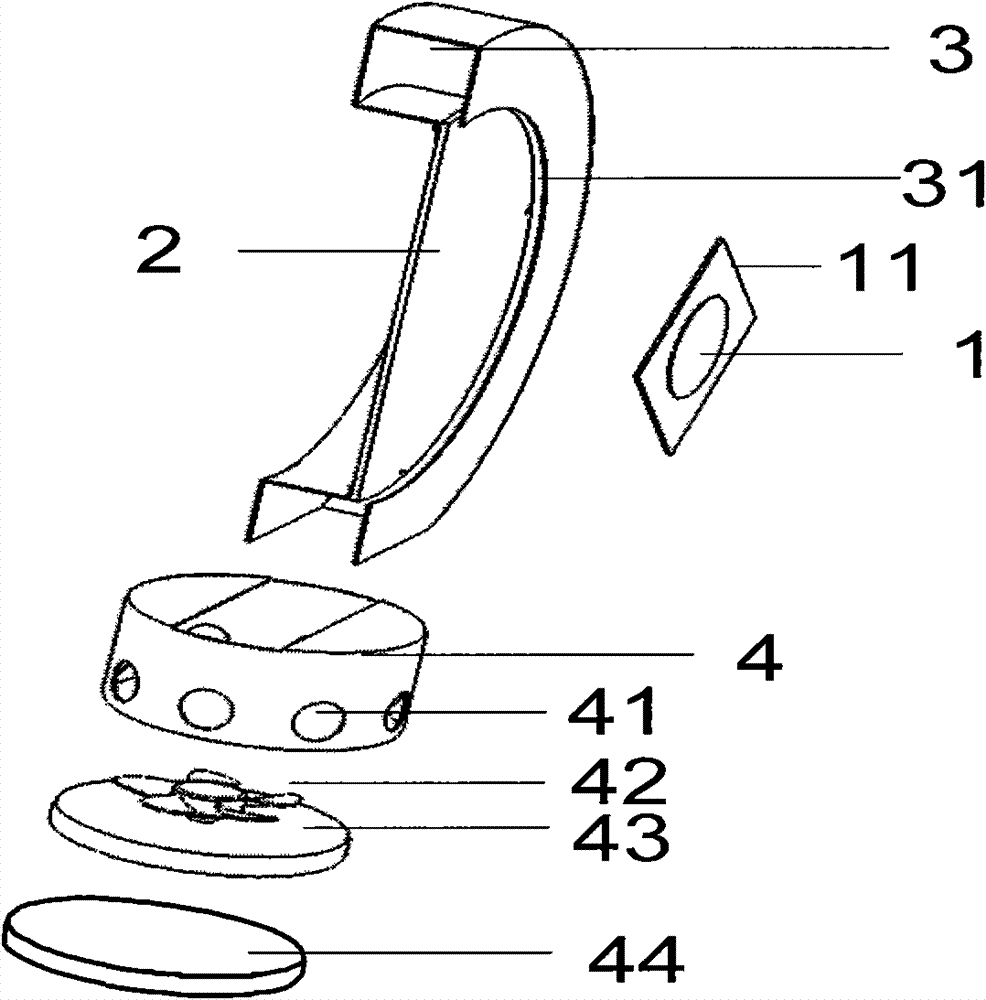

[0031] figure 1 It is a structural diagram of the LED heat dissipation package with side air outlets of the present invention, image 3 Its assembly diagram is also an embodiment of the present invention, diagram 2-1 with Figure 2-2 for figure 1 A-A surface (vertically bisecting the cross-section of the flat mounting plate 2 and the surrounding hollow flow channel 3); it can be seen from the figure that the LED heat dissipation package structure with side air outlets of the present invention includes:

[0032] A flat mounting plate 2 as a heat sink for the LED light-emitting module;

[0033] A surrounding hollow flow channel 3 surrounding the side walls around the flat mounting plate 2, and a surrounding slit-shaped opening 31 is provided on the inner flow channel wall of the surrounding hollow flow channel 3;

[0034] A hollow base 4 that is located at the lower end of the surrounding hollow flow channel 3 and communicates with the surrounding hollow flow channel 3; a h...

Embodiment 2

[0046] attached Figure 4 It is a schematic cross-sectional view of an LED heat dissipation package structure with side air outlets (surrounding slit-like openings 31 ) at the front and back of the flat mounting plate 2 ; it is also another embodiment of the present invention.

[0047] It can be seen from the figure that all the structures of this embodiment are the same as those of Embodiment 1 except that surrounding slit-like openings 31 (side air outlets) are provided at the front and back of the flat mounting plate 2 . At this time, in addition to setting a surrounding slit-shaped opening before the flat mounting plate 2, a surrounding slit-shaped opening is also set behind the flat mounting plate 2; the advantage of this structure is that through the flat mounting plate The surrounding slit-shaped opening behind the plate 2 cools the rear end of the flat mounting plate 2, which can further enhance the heat dissipation effect, thereby ensuring the safe and stable operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com