Method of drying a honeycomb formed body

A drying method and a technology of formed bodies, which are applied in the drying of solid materials, progressive dryers, and drying of ceramic products. It can solve the problems of honeycomb structure size deviation, cracks, and uneven power line density, and reduce the deterioration of the cross-sectional shape. , good dimensional accuracy

Active Publication Date: 2011-11-09

NGK INSULATORS LTD

View PDF10 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

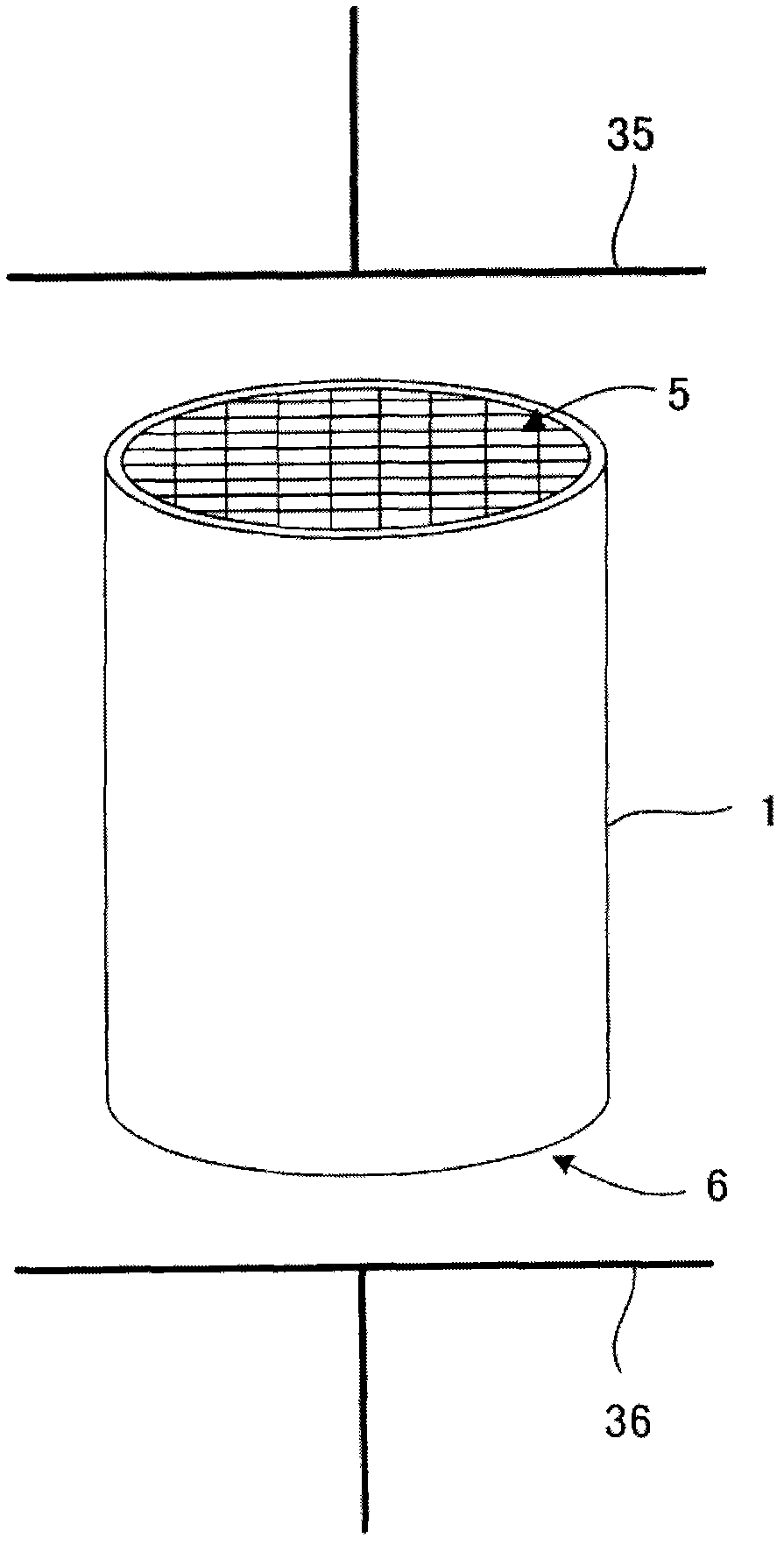

[0006] In dielectric drying, the density of the electric force lines passing through the formed honeycomb body tends to become non-uniform, thereby sometimes causing partial drying delays on the formed honeycomb body, resulting in dimensional variations in the obtained honeycomb structure, Cracks and other issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0056] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

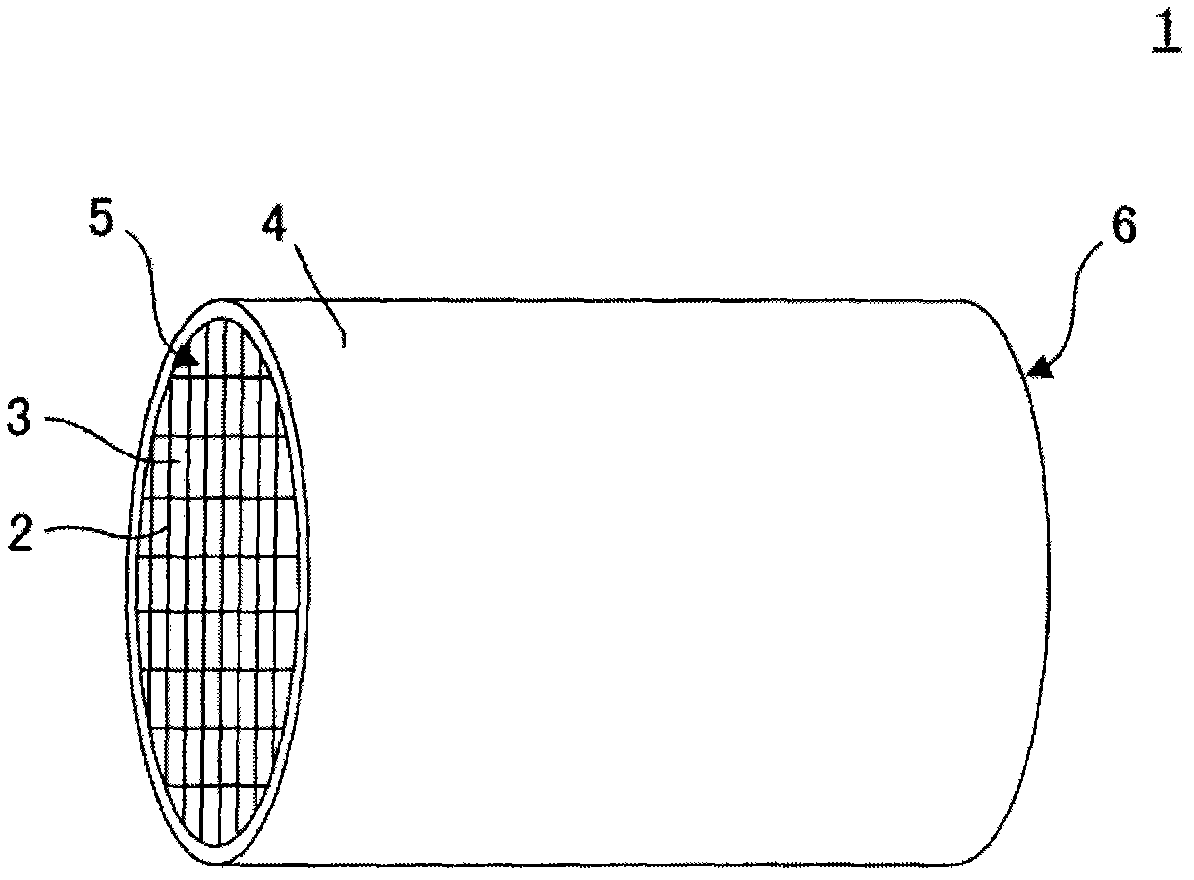

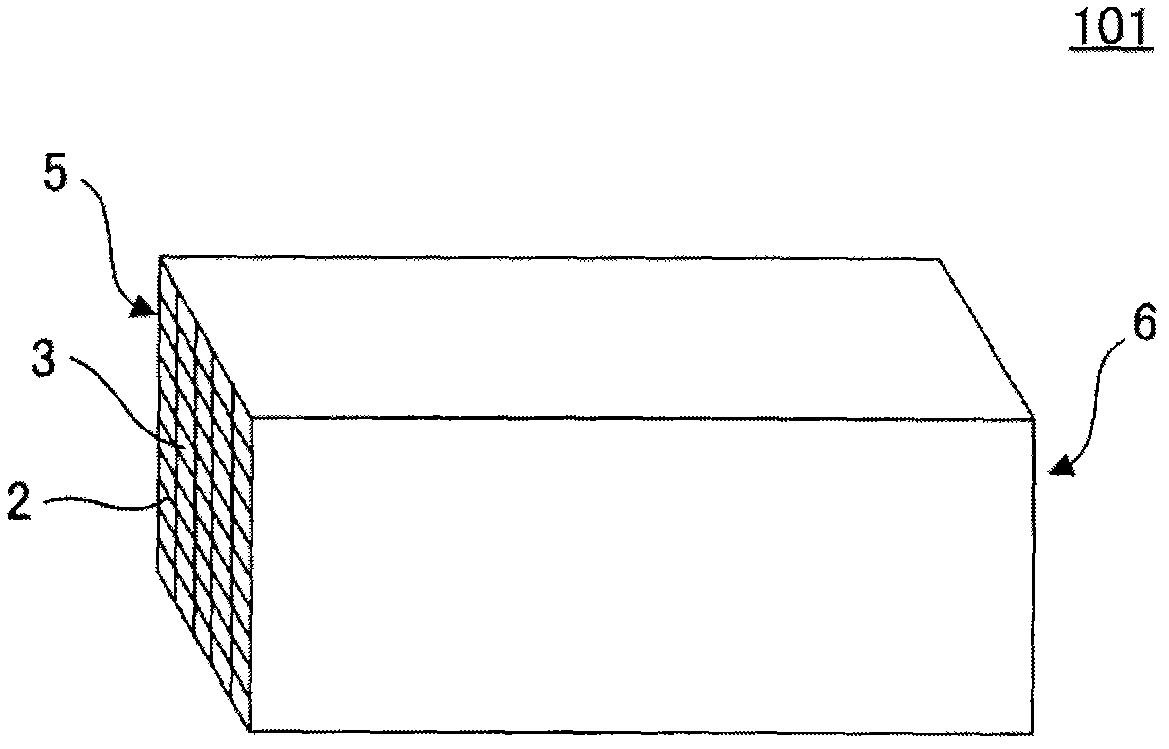

The present invention relates to a method of drying honeycomb formed bodies. More specifically, the present invention relates to a method of drying honeycomb formed bodies with which they cannot easily be affected by an atmosphere in a dry space and can be dried without occurrence of deformation and cracks of outer peripheries thereof even when partition walls thereof are thin. The method of drying a ceramic formed body comprising the step of performing dielectric drying on an unfired honeycomb formed body formed with a ceramic material as a main raw material under a condition that a power density is 5 to 20 [kW / kg (water)].

Description

technical field [0001] The present invention relates to a method for drying a formed honeycomb body. More specifically, it relates to a method for drying a formed honeycomb body that is less affected by the atmosphere in the drying space even when the partition walls are thin, and can be dried without deformation or cracks in the outer periphery. Background technique [0002] Honeycomb structures made of ceramics are widely used for catalyst supports, various filters, and the like. Recently, attention has been drawn to a diesel particulate filter (DPF) for capturing particulate matter (particulate matter) discharged from a diesel engine. [0003] In general, such a honeycomb structure can be obtained by adding forming aids and various additives to a dispersion medium such as a ceramic material and water to obtain a raw material composition, kneading the raw material composition, and forming a billet After soiling, extrusion molding is performed to produce a honeycomb-shape...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F26B3/34C04B38/00

CPCF26B3/347C04B35/6365F26B15/16C04B2235/606C04B35/6263F26B3/343C04B35/195F26B2210/02B28B11/241B28B11/243C04B38/0006C04B2111/00793C04B38/0054

Inventor 奥村健介高木周一

Owner NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com