Large-diameter anchor cable for mine

A large-diameter, anchor-cable technology, applied in mining equipment, bolt installation, earthwork drilling, etc., can solve the problems of high construction safety hazards, high noise pollution, and high labor intensity, and achieve low cost, convenient construction, and reduced diameter poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

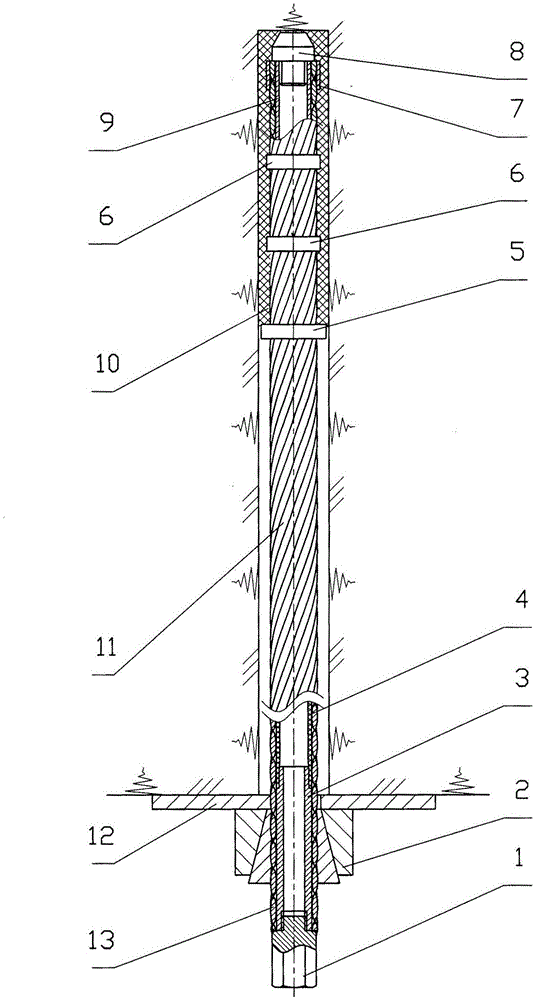

[0020] in figure 1 A structure of the present invention is shown in the figure, that is, the resin anchoring section of the cable body is a large-diameter mine anchor cable with a cable hoop-type enlarged diameter structure. It is composed of a cable body 11, an anchor 2, a supporting plate 12, and a mixing joint 1. The cable body 11 is composed of a cable body wire 13, a head rigid core tube 9, a flexible core tube 4, a tail rigid core tube 3, a choke hoop 5, a cable hoop 6, a head hoop 7, and a guide cable head 8.

[0021] The front part of the anchor cable body 11 is a resin anchoring section where the resin anchoring agent 10 is used for end anchoring. The anchor 2 and the supporting plate 12 are installed on the cable body 11 at the tail of the anchor cable. The stirring joint 1 is fixedly connected to the tail end of the cable body, that is, the rear end of the rigid core tube at the tail, and is fixedly connected to the cable body wire 13. In the figure, the upper part o...

Embodiment 2

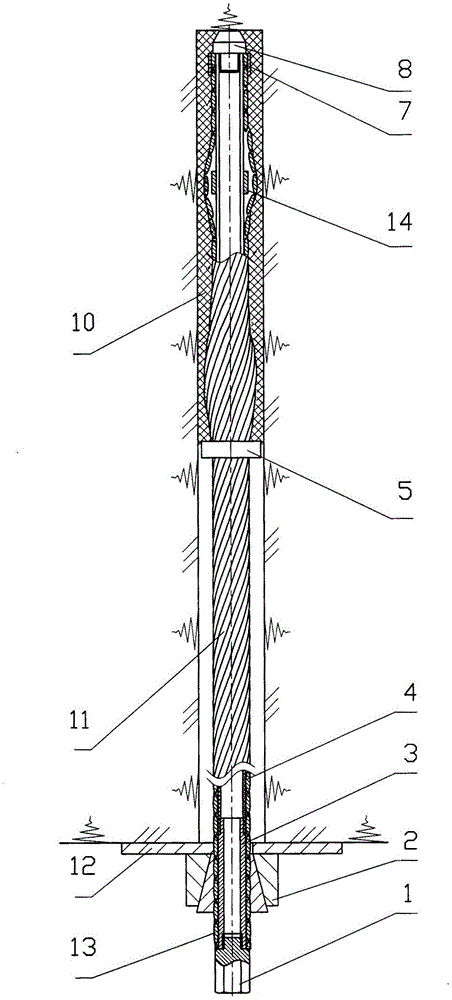

[0037] in figure 2 Another structural form of the present invention is shown in the figure, that is, the cable body resin anchoring section is a large-diameter mine anchor cable with a ring-expanded diameter structure. It is composed of a cable body 11, an anchor 2, a supporting plate 12, and a mixing joint 1. The cable body 11 consists of a cable body steel wire 13, a head rigid core tube 9, a flexible core tube 4, a tail rigid core tube 3, a choke hoop 5, a cable hoop 6, a head hoop 7, a guide cable head 8, and an expansion The ring 14 constitutes.

[0038] The expanded diameter structure adopted in the cable body resin anchoring section in this example is an expanding ring type, that is, the cable body high-strength steel wire in the resin anchoring section between the choke hoop 5 and the head hoop 7 on the cable body resin anchoring section An expansion ring 14 is added between 13 and the rigid core tube 9 of the head, so that the part where the expansion ring 14 is added ...

Embodiment 3

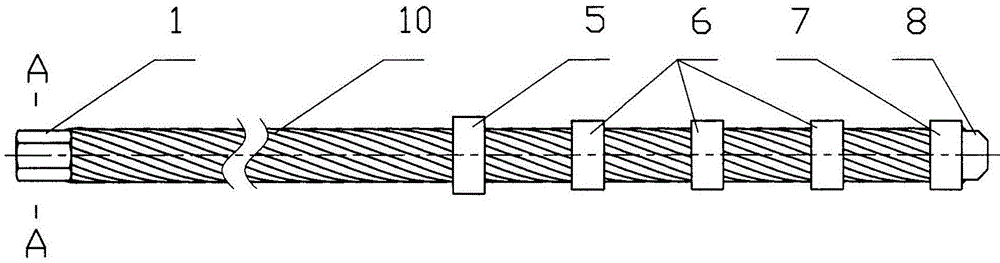

[0041] in Figure 5 The third structural form of the present invention is shown in the figure, that is, the resin anchoring section of the cable body is a large-diameter mine anchor cable with a steel wire outer-wound expanded diameter structure. It is composed of a cable body 11, an anchor 2, a supporting plate 12, and a mixing joint 1. The cable body 11 consists of a cable body steel wire 13, a head rigid core tube 9, a flexible core tube 4, a tail rigid core tube 3, a choke hoop 5, a cable hoop 6, a head hoop 7, a guide cable head 8, and outer It is constructed around steel wire 15.

[0042] The steel wire outer-winding type expansion structure, that is, a cable hoop 6 is arranged between the choke hoop 5 and the head hoop 7 on the resin anchor section of the cable body, and the cable hoop 6 is placed between the choke hoop 5 and the cable hoop 6 Between the hoop 6 and the head hoop 7, an outer winding steel wire 15 having a diameter larger than that of the cable body high-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com