Automatic back pressure control device

A technology of automatic control device and back pressure valve, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve problems such as high simulated temperature, burns, failure of back pressure control, etc., to achieve accurate experimental data, reduce the degree of influence, and use safely reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

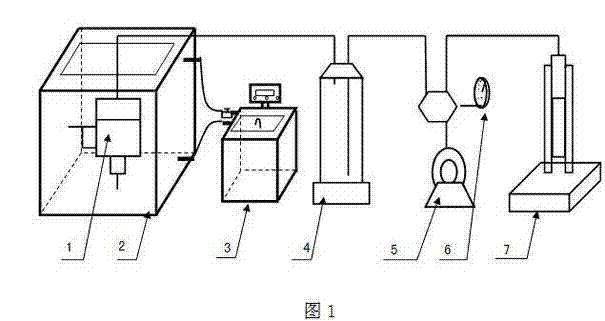

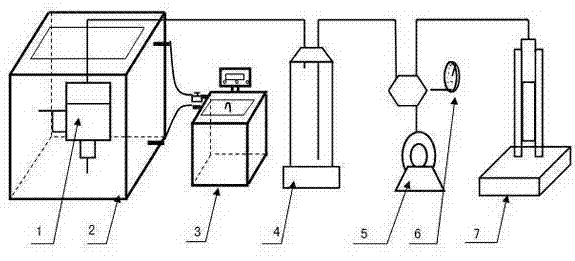

[0010] As shown in Figure 1, a back pressure automatic control device includes a back pressure valve 1, a thermostat 2, and is connected to an air compressor 5 and an automatic tracking pump 7, and the thermostat 2 is externally connected to it Automatic temperature control device. The function of setting the temperature automatic control device is to form a second temperature field in the thermostatic device equipped with a back pressure valve to realize automatic control of the temperature of the output material at the outlet of the system pipeline. The back pressure valve 1 is a double diaphragm piston type back pressure valve. The temperature automatic control device is a low temperature constant temperature circulator 3. The cryostat circulator 3 can realize precise adjustment and control over a larger temperature range. An intermediate container 4 is provided between the back pressure valve 1 and the air compressor 5, and the intermediate container 4 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com