Operation method of powder sintering device

An operation method and powder technology are applied in the field of operation of powder sintering equipment, which can solve the problems of increasing the scale of powder sintering equipment and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

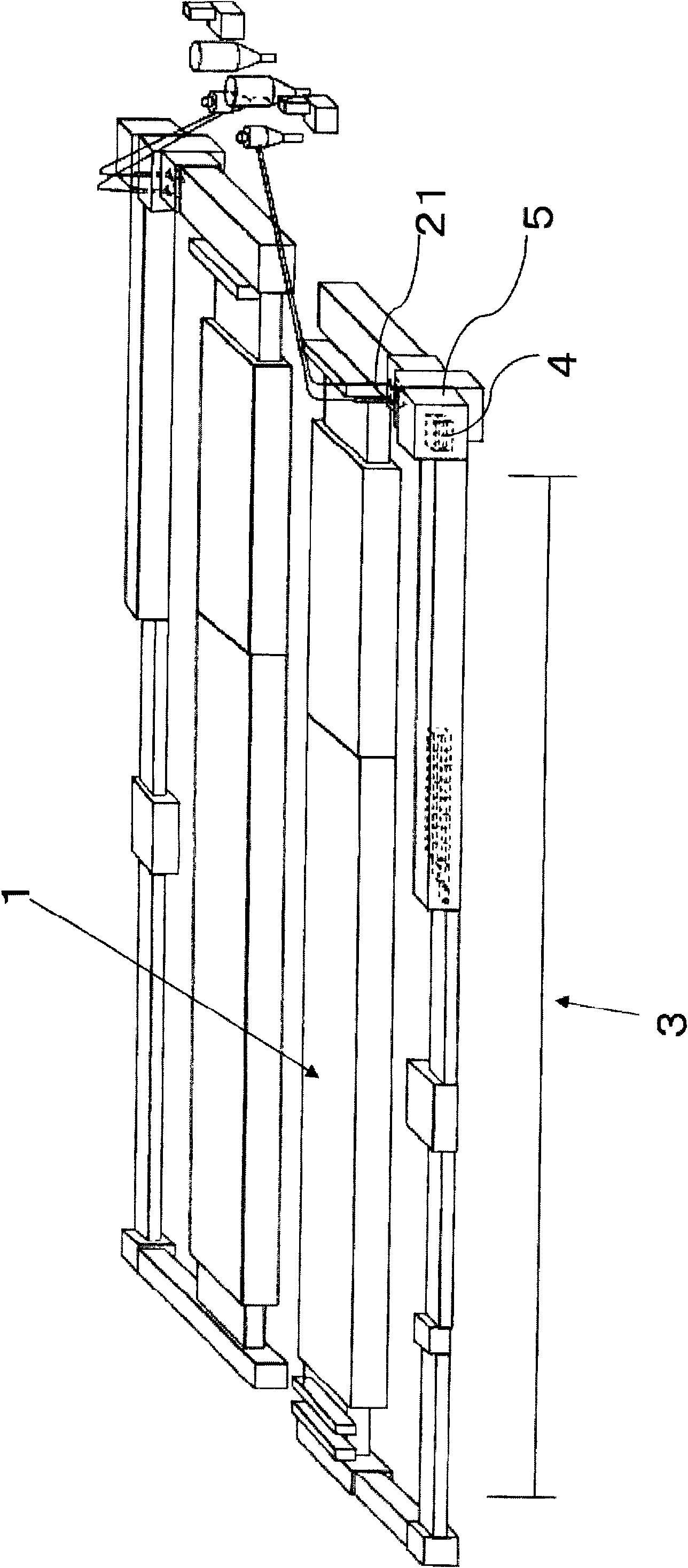

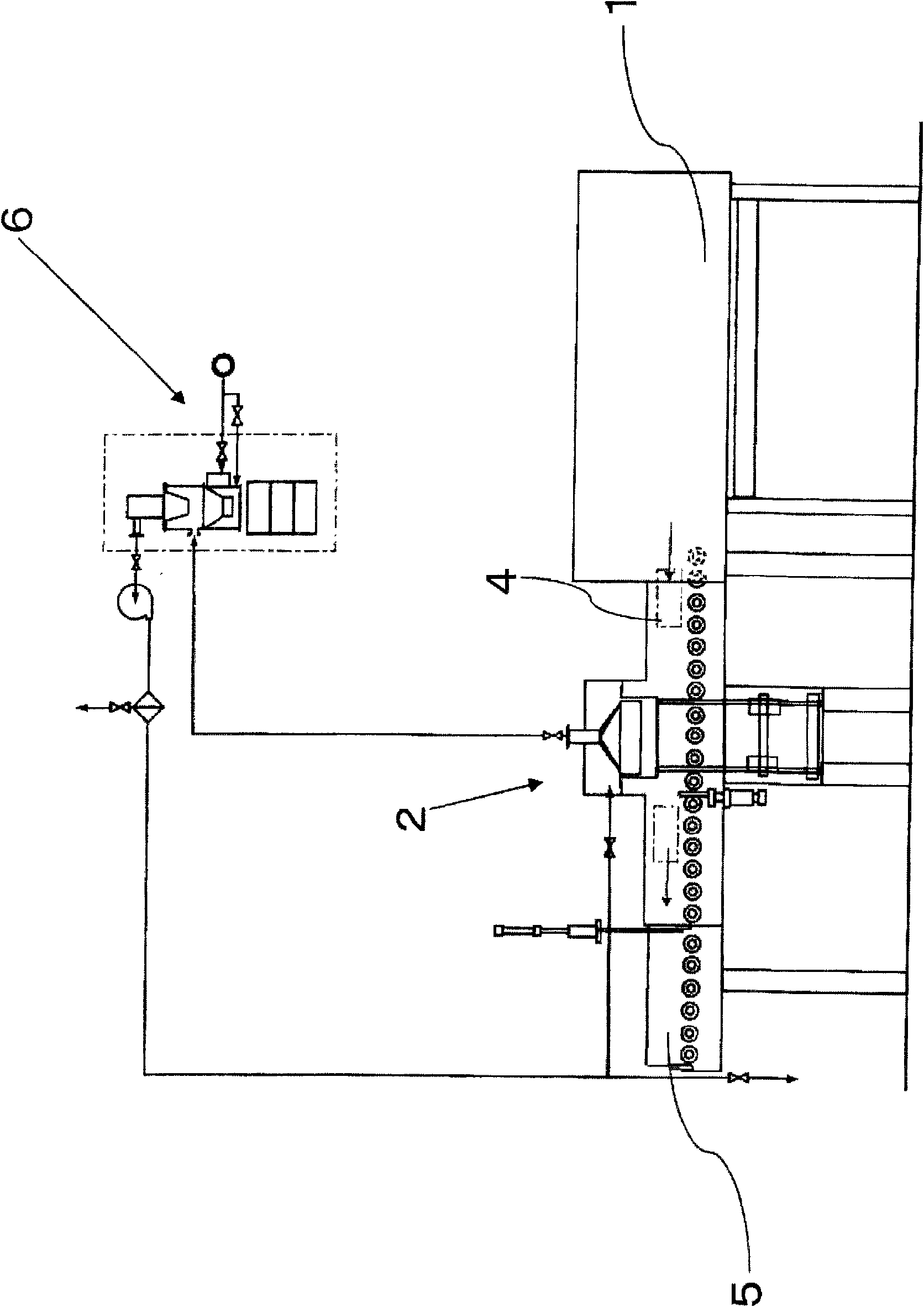

[0033] Next, preferred embodiments of the present invention are shown. figure 1 It is a diagram for explaining the overall structure of powder firing equipment, figure 2 It is a figure for explaining the powder recovery unit used in the powder recovery process, and in each drawing, 1 indicates a continuous firing furnace, 2 indicates a powder recovery unit, 3 indicates an empty sagger conveyance path, and 4 Indicates a sagger.

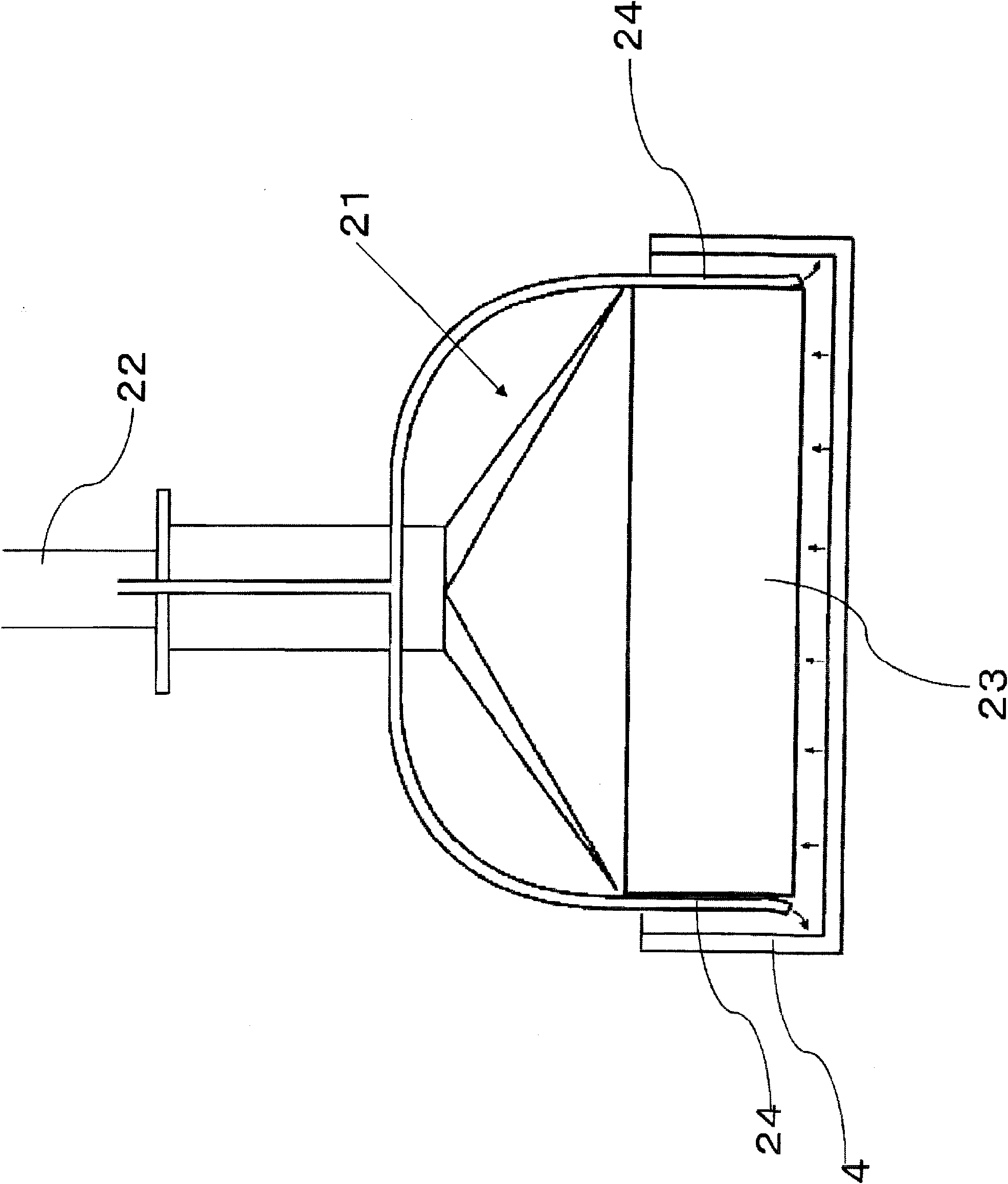

[0034] Such as figure 2 As shown, the powder recovery unit 2 has a powder suction nozzle 21 for sucking the powder in the sagger and a conveyance path 22 for conveying the powder sucked by the powder suction nozzle 21, and, as image 3 and Figure 4 As shown, the powder suction nozzle 21 has a scraper-shaped suction port 23 whose long side is approximately equal to the length of one side of the sagger, and has a gas nozzle 24 on the outer surface of the short side of the suction port 23 .

[0035] Such as figure 1 As shown, the powder sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com