Thermal insulating coating and preparation method thereof

A technology of heat-insulating coatings and coatings, applied in the direction of polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of imperfect thermal insulation performance, increased raw material costs, high costs, etc., to ensure light transmission and insulation Effects of thermal performance, production cost reduction, and raw material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

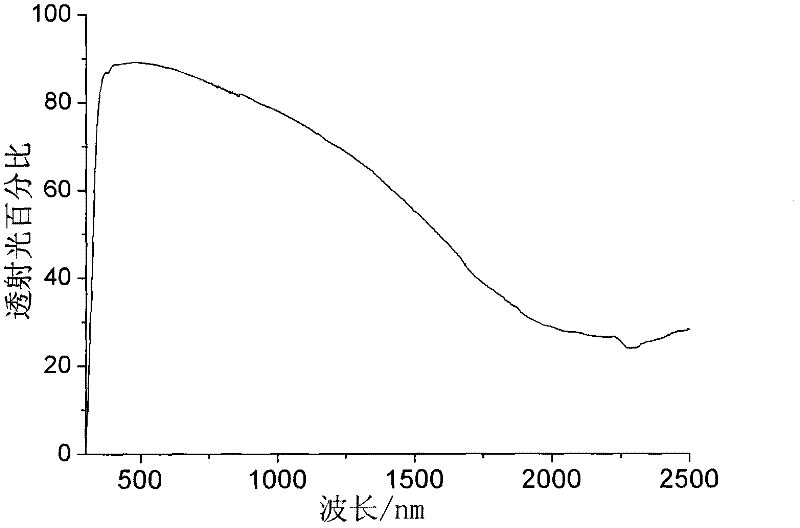

[0027] Do the following with the components specified in Table 1 below: Mix 5 parts of sulfide (Cu 1.4 S), 10 parts of ATO and / or ITO (5 parts of ATO, 5 parts of ITO), 1 part of dispersant (1 part of Hydropalat 3275), 35 parts of solvent (35 parts of water) are mixed to form a mixture; under stirring and ultrasonic conditions Disperse the mixture for 10 minutes; then disperse the mixture by ball milling for 10 hours at 550 rpm to form a thermal insulation slurry.

[0028] Add 49% film-forming agent (30% water-based polyurethane, 10% polyvinyl alcohol and 9% polyvinyl butyral) to the above-mentioned thermal insulation slurry under vigorous stirring to form a uniform thermal insulation coating. The coating was evenly brushed on the glass surface to form a coating film, and then the infrared blocking rate and visible light transmittance of the film were tested, and the measurement results are shown in Table 1.

Embodiment 2

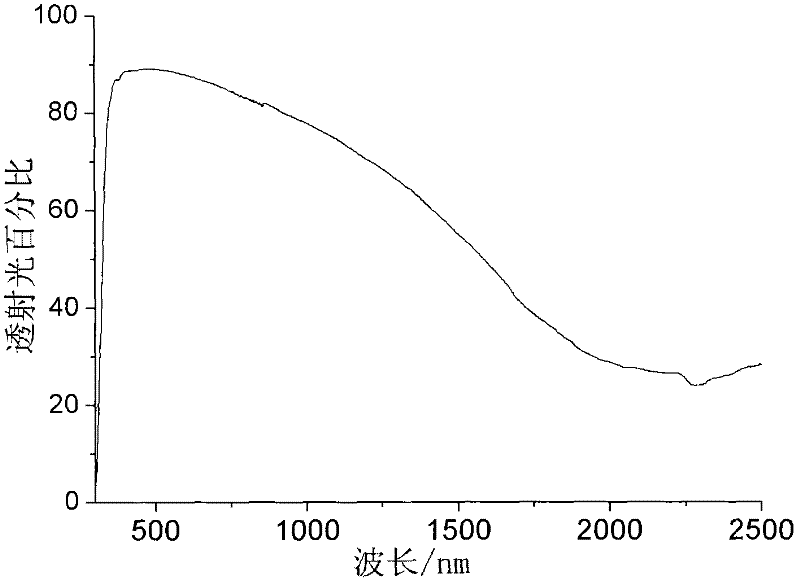

[0030] The method of Example 1 was repeated according to the content of each component and the process conditions specified in Table 1 below. See Table 1 for the measurement results of the infrared rejection rate of the thermal insulation coating film in this example.

Embodiment 3

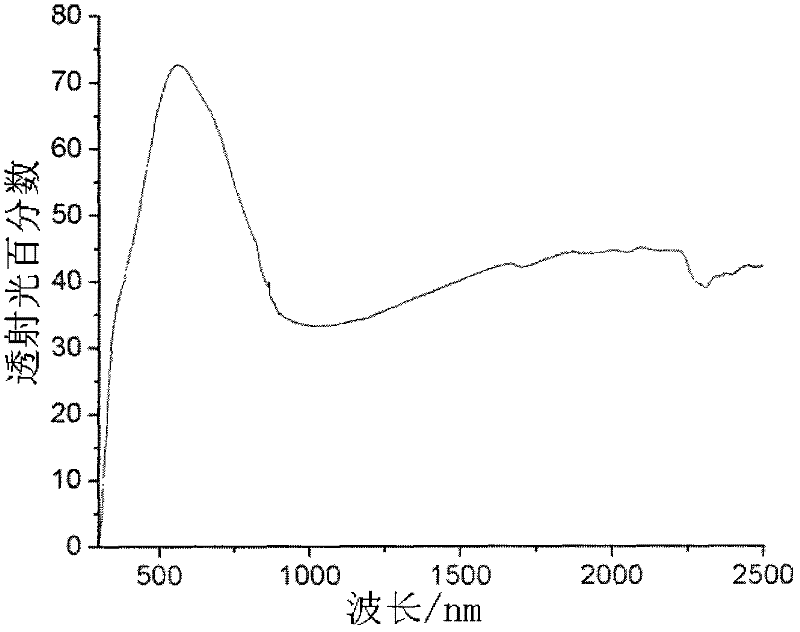

[0032] The method of Example 1 was repeated according to the content of each component and the process conditions specified in Table 1 below. See Table 1 for the measurement results of the infrared rejection rate of the thermal insulation coating film in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com