Treatment equipment and process of oily sludge and sand

A treatment device and treatment process technology, applied in the petroleum industry, pyrolysis treatment of sludge, coking carbonaceous materials, etc., can solve the problems of hidden dangers of environmental pollution, land occupation, waste of resources, etc., achieve good social benefits, create social, Harmonious society effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

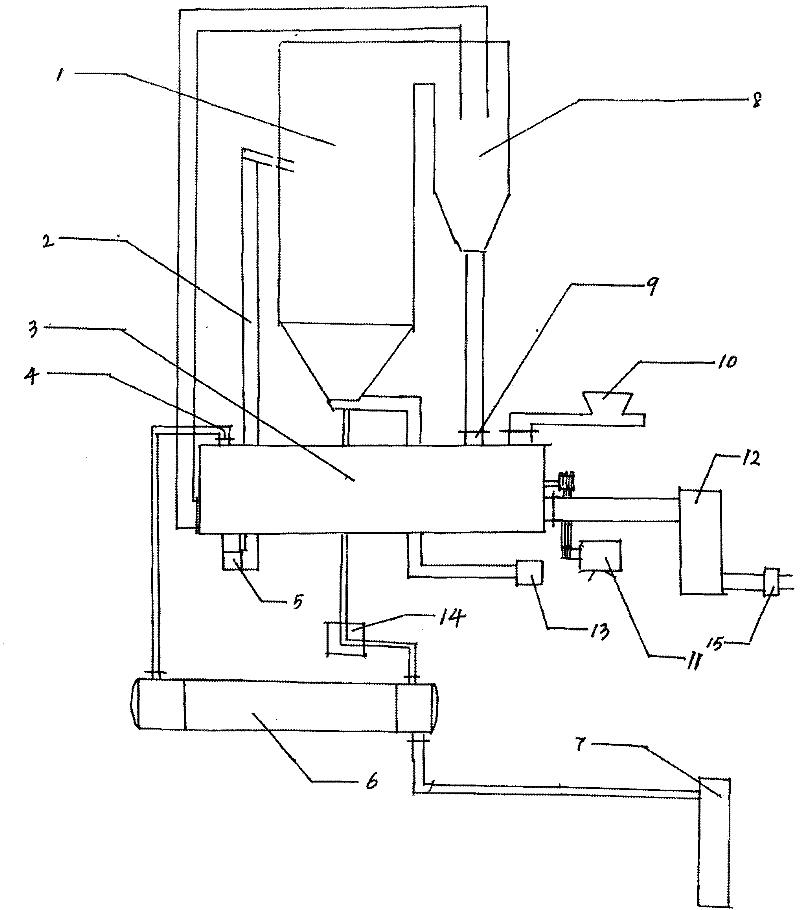

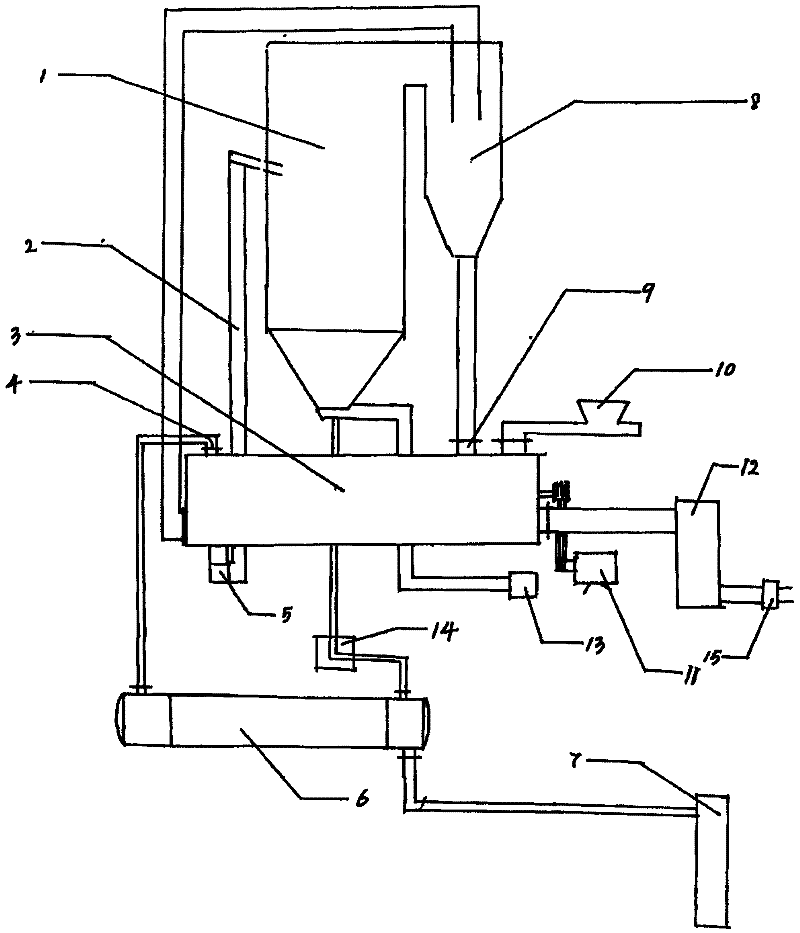

[0041] combined with figure 1 , to further describe the present invention:

[0042] An oil sludge sand treatment device, its technical proposal is mainly composed of a fluidized bed 1, a hopper 2, a rotary kiln 3, an oil and gas outlet 4, a thermosolid carrier outlet 5, a condenser 6, a liquid oil storage tank 7, and a cyclone separator 8. Thermosolid carrier return port 9, original oil sludge sand inlet 10, rotary kiln drive motor 11, blower 13, gas inlet fluidized bed pipeline 14, slag discharge port 15, one side of the rotary kiln 3 is provided with an original The oil sludge sand inlet 10, the heat solid carrier return port 9, the rotary kiln drive motor 11 and the slag discharge port 15, the other side is provided with an oil gas outlet 4 and a heat solid carrier discharge port 5, and the oil gas outlet 4 is connected to the condenser 6, The thermal solid carrier outlet 5 communicates with the fluidized bed 1 through the hopper 2, and the fluidized bed 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com