Synechococcus engineering bacterium capable of improving yield of cellulose, and preparation method and application thereof

A technology of engineering bacteria and cellulose, applied in the biological field, can solve problems such as pollution, unsuitable cultivation and production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

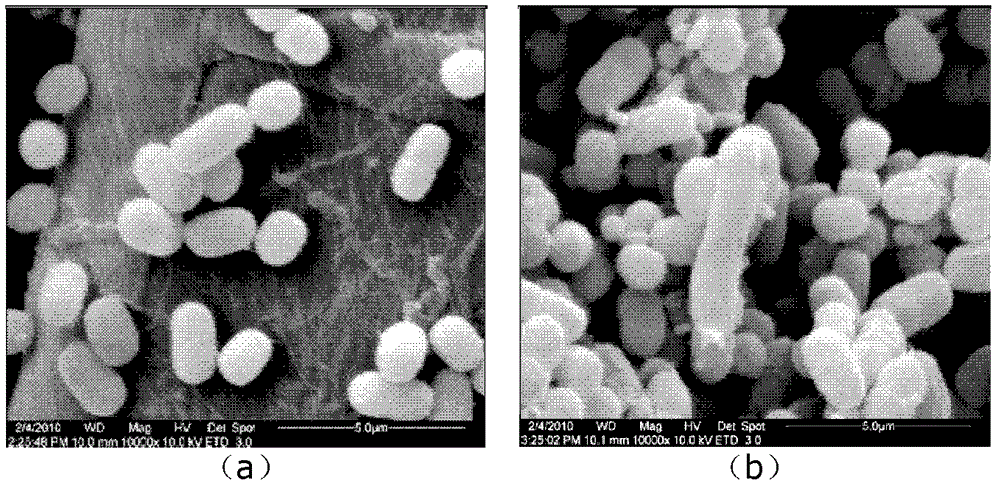

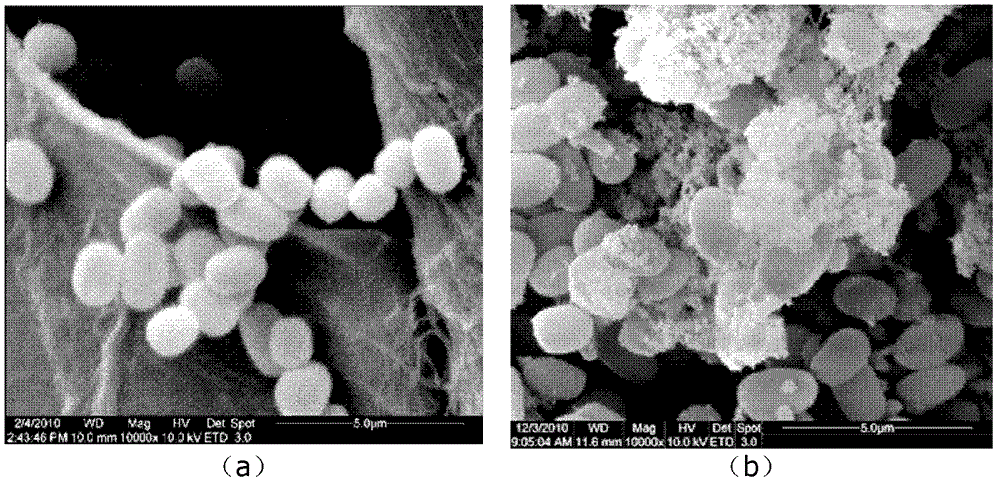

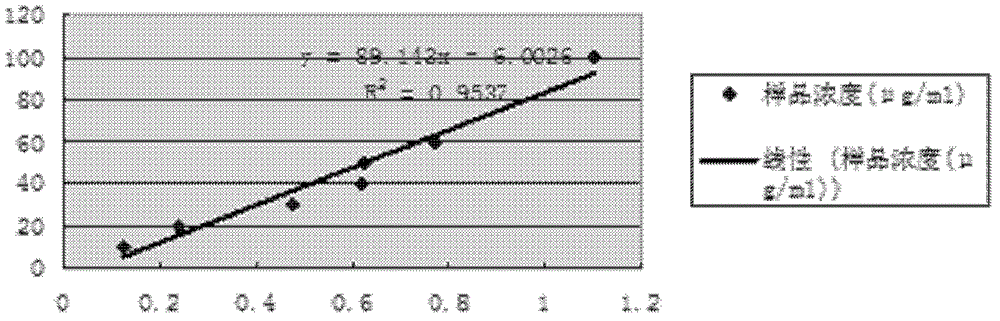

[0029] 1. First, the cellulose synthesis gene cesA (SEQ ID NO: 1) of the cyanobacterium Synechococcus sp. Select a suitable length of DNA fragments at the 5' and 3' ends of the target gene to be knocked out, generally from 400bp to 3Kb. A kanamycin resistance gene is inserted in the middle of the two fragments, and then The three connected fragments are inserted together into a vector that cannot be replicated in cyanobacteria, and the vector is transferred into cyanobacteria, and under the selection of kanamycin, homologous double exchange occurs on the cyanobacteria genome, so that the target gene is replaced by the antibiotic gene. Replaced, so as to achieve the knockout of the target gene. After gene knockout, the original cesA gene deletion, and completely replaced by the kanamycin resistance gene. In addition, the kanamycin resistance gene is inserted into cesA, and The method of not completely knocking out this gene can also make this gene lose its function. In this exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com