Double-layer polyethylene composite tubular product with ultrahigh molecular weight

A polyethylene composite pipe, ultra-high molecular weight technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., to achieve long service life, wide application range, and eliminate the pressure in the pipe or the effect of corrosion or damage by corrosive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

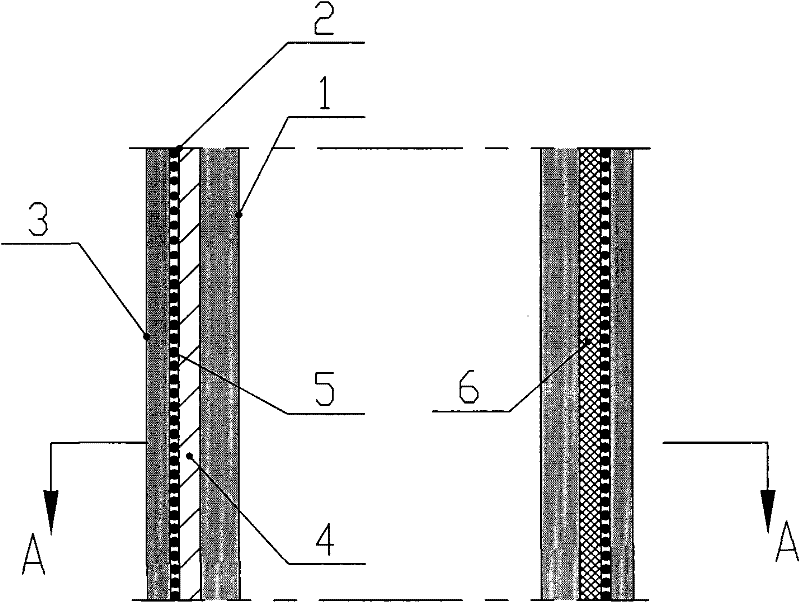

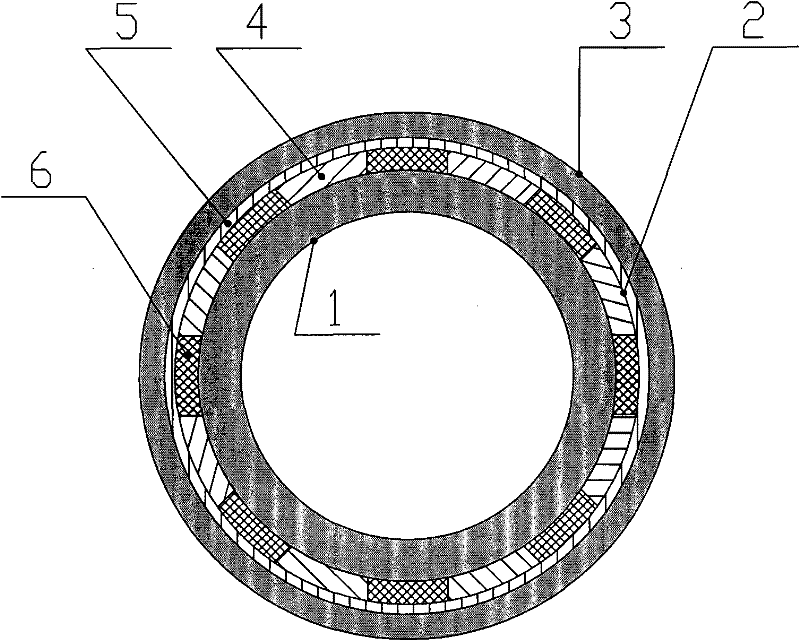

[0019] The invention as figure 1 As shown, a double-layer ultra-high molecular weight polyethylene composite pipe is provided as a four-layer composite structure, including an inner wall, a metal layer, and an outer wall. The metal layer is placed between the inner wall and the outer wall, and the steel strip layer and Composed of steel wire layers, the steel belt layer is placed between the steel wire layer and the inner wall, and the steel wire layer is placed between the steel belt layer and the outer wall.

[0020] The steel belt layers are equidistantly arranged along the direction parallel to the axis of the pipe, the thickness of the steel belts is 0.5-3 mm, and the distance between the steel belts is 10-20 mm.

[0021] The steel strip layer is coated with polyethylene hot-melt adhesive, which is available in the market, and its coating thickness is 0.7-3.0 mm.

[0022] The steel wire layer is in a spiral winding structure wrapped with a steel belt layer in a direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com