Composite lithium-rich anode material, its preparation method and its application

A lithium-rich material and mixed solution technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as limiting competitive advantages and wide applications, low stability and poor cyclability of lithium-rich materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

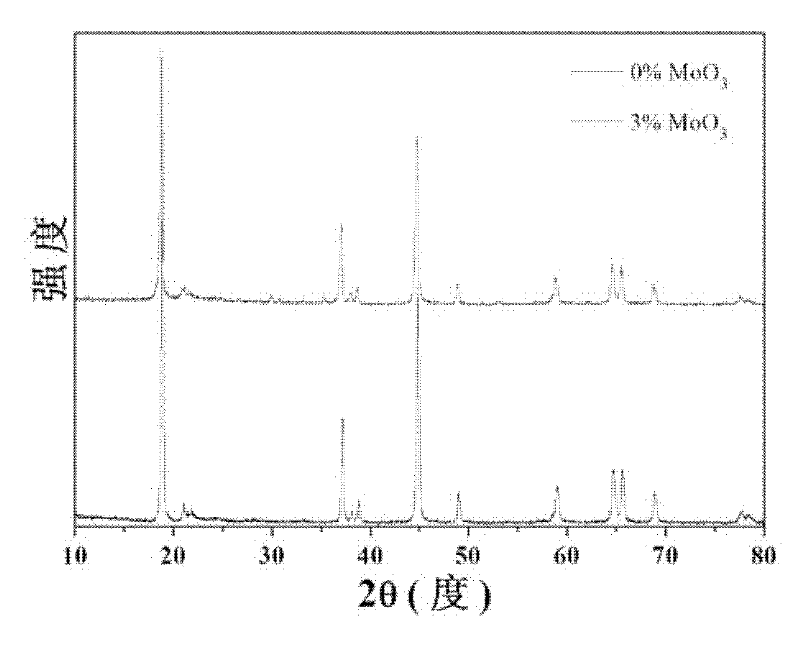

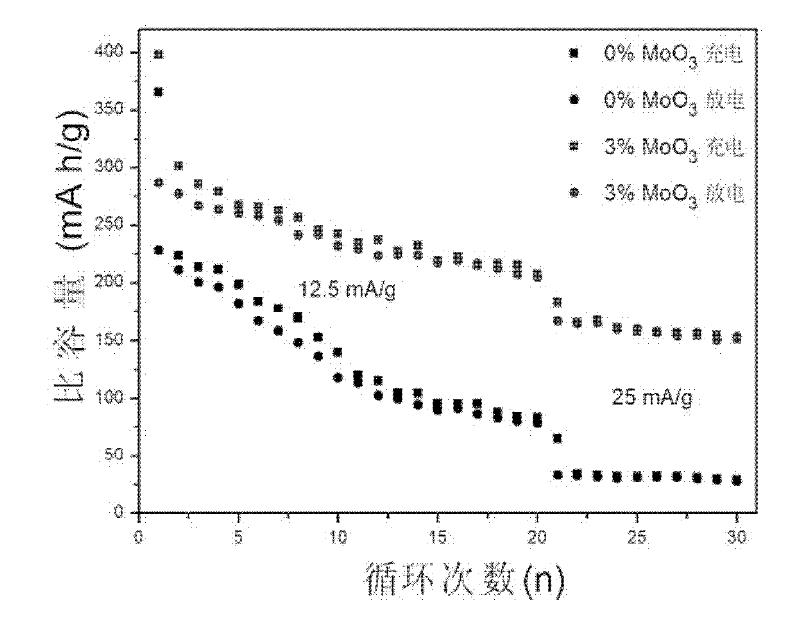

[0026] Embodiment 1, preparation Li[Li 1-x-y-z mn x co y Ni z ]O 2 Lithium-containing materials shown (x=0.5, y=z=0.2)

[0027] 1) According to the molecular formula Li[Li 0.1 mn 0.5 co 0.2 Ni 0.2 ]O 2 Mn(CH 3 COO) 2 , Co(CH 3 COO) 2 , Ni(CH 3 COO) 2 The mixed aqueous solution, the cation concentration is 0.2mol / L;

[0028] 2) Add the mixed solution and 10mol / L LiOH solution dropwise into the reaction vessel, control the pH value of the system at about 10.5, and heat the water bath to 60°C. After the reaction is completed, filter, wash, and dry for 8 hours in a vacuum oven at 100°C with a vacuum degree of -85KPa to obtain the precursor [Mn 0.56 co 0.22 Ni 0.22 ](OH) 2 ;

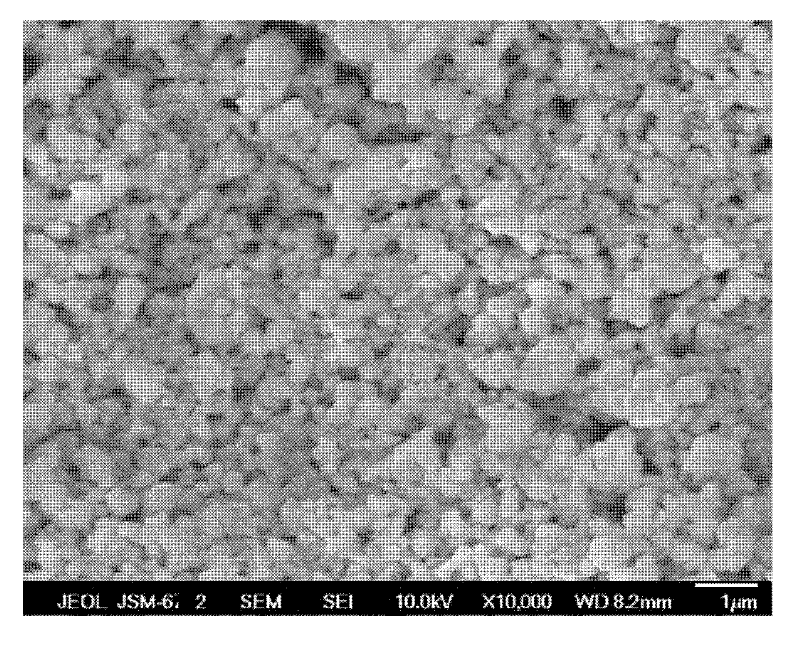

[0029] 3) Combine the precursor with LiOH·H 2 O according to the molecular formula Li[Li 0.1 mn 0.5 co 0.2 Ni 0.2 ]O 2 After the proportions in the mixture are uniformly mixed, pre-sintering is carried out at 450°C for 6h in an air atmosphere, and then calcined at 900°C for 12h to ob...

Embodiment 2

[0032] Embodiment 2, preparation Li[Li 1-x-y-z mn x co y Ni z ]O 2 The shown lithium-containing materials (x=0.5, y=z=0.2) and the corresponding composite lithium-rich cathode materials

[0033] 1) According to the molecular formula Li[Li 0.1 mn 0.5 co 0.2 Ni 0.2 ]O 2 Mn(CH 3 COO) 2 , Co(CH 3 COO) 2 , Ni(CH 3 COO) 2 The mixed aqueous solution, the cation concentration is 0.2mol / L;

[0034] 2) Add the mixed solution and 10mol / L LiOH aqueous solution dropwise into the reaction vessel, control the pH value of the system at about 10.5, and heat the water bath to 60°C. After reacting for 12 hours, filter, wash, and dry for 8 hours in a vacuum oven at 100°C with a vacuum degree of -85KPa to obtain the precursor [Mn 0.56 co 0.22 Ni 0.22 ](OH) 2 ;

[0035] 3) Combine the precursor with LiOH·H 2 O according to the molecular formula Li[Li 0.1 mn 0.5 co 0.2 Ni 0.2 ]O 2 After the proportions in the mixture are uniformly mixed, pre-sintering is carried out at 450°...

Embodiment 3

[0041] Embodiment 3, preparation Li[Li 1-x-y-z mn x co y Ni z ]O 2The shown lithium-containing materials (x=0.6, y=z=0.1) and the corresponding composite lithium-rich cathode materials

[0042] 1) According to the molecular formula Li[Li 0.2 mn 0.6 co 0.1 Ni 0.1 ]O 2 Mn(NO 3 ) 2 , Co(NO 3 ) 2 , Ni(NO 3 ) 2 mixed ethanol solution with a cation concentration of 0.5mol / L;

[0043] 2) Add the mixed solution and 5mol / L KOH aqueous solution dropwise into the reaction vessel, control the pH value of the system at about 12, and heat the water bath to 70°C. After reacting for 5 hours, filter, wash, and dry in a vacuum oven at 90°C with a vacuum degree of -95KPa for 10 hours to obtain the precursor [Mn 0.75 co 0.125 Ni 0.125 ](OH) 2 ;

[0044] 3) Combine the precursor with CH 3 COOLi according to the molecular formula Li[Li 0.2 mn 0.6 co 0.1 Ni 0.1 ]O 2 After the proportions in the mixture are uniformly mixed, pre-sintering is carried out at 400° C. for 8 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com